Aromatic hydrocarbon extraction method

An aromatic hydrocarbon extraction and aromatic hydrocarbon technology, which is applied in the directions of extraction and purification/separation, multi-stage series-connected refining process treatment, etc. The effect of backwash strength, small footprint, and wide adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

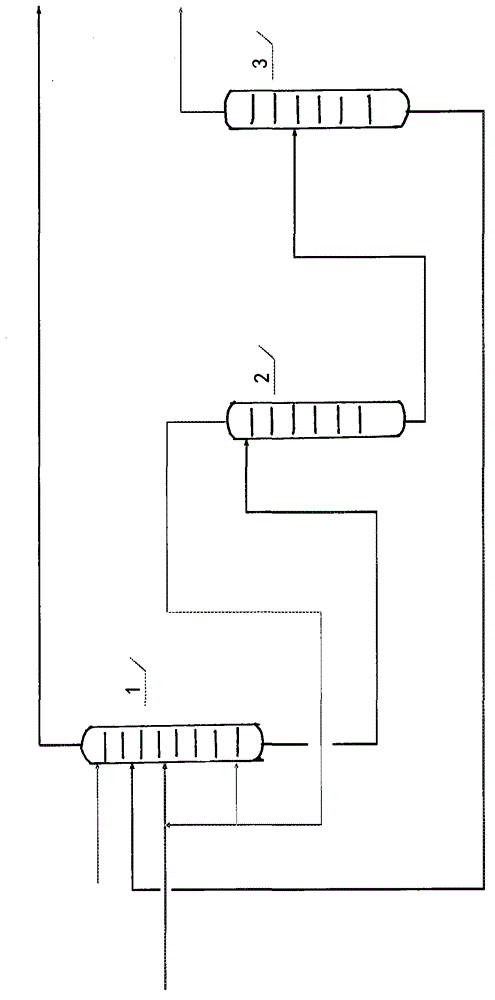

[0024] Such as figure 1 Shown is a schematic flow diagram of an embodiment of the present invention, and some auxiliary equipment such as tanks, pumps, heat exchangers, condensers, etc. are not marked in the figure, but this is well known to those skilled in the art.

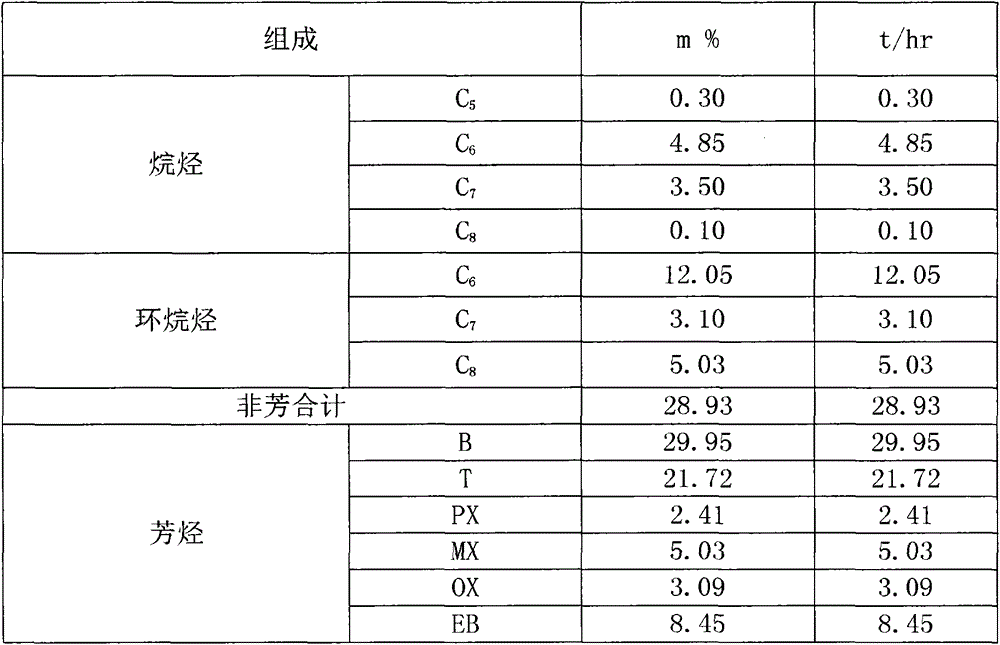

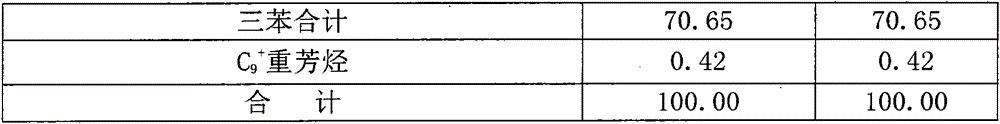

[0025] Such as figure 1 Shown, C6-C9 component gasoline, aromatics content is 70.65% (see Table 1-1 for raw material properties) with the flow rate of 100 tons / hour and the flow rate of 300 tons / hour with solvent and add extraction tower 1 together and extract, The temperature of the extraction tower 1 is 90° C., the pressure is 0.7 MPa, the solvent ratio is 3, the solvent used is sulfolane, the aromatics content of the obtained raffinate is 0.3%, and the solvent content is 2 ppm. Washing water enters the upper part of the extraction tower at a flow rate of 3.0 tons / hour, and the obtained raffinate oil after washing is sent out of the device at a flow rate of 28.96 tons / hour. The first rich solvent obtained fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com