Down-the-hole drilling

A technology for down-the-hole drilling and drill racks, which is applied to drill pipes, drill pipes, and drilling equipment. It can solve problems affecting construction progress, blockage of impactors, and high fuel consumption, so as to save construction time, reduce friction loss, The effect of walking and moving is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

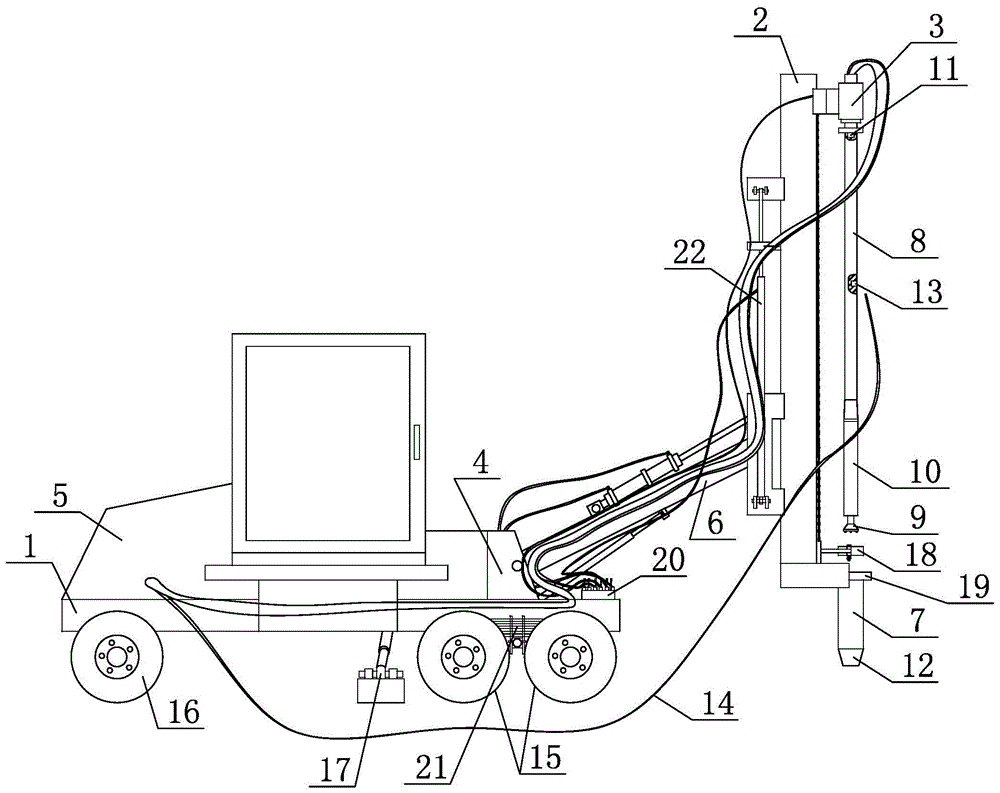

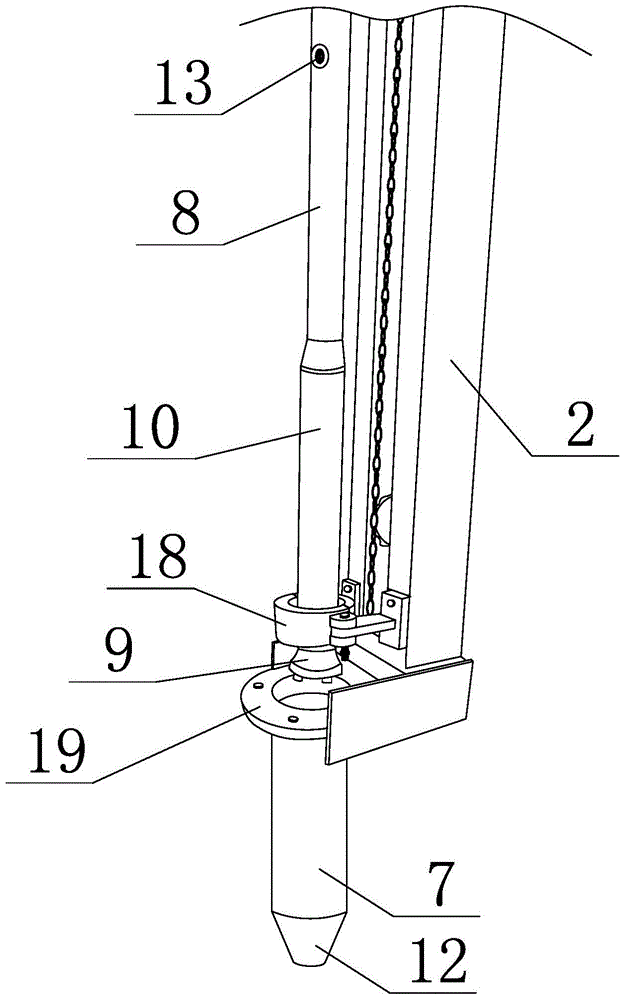

[0015] refer to figure 1 and figure 2 As shown, the down-the-hole drill disclosed by the present invention includes a frame 1, a drill frame 2, a rotary air supply mechanism 3 and a drilling tool, and the frame 1 is equipped with a walking chassis, a hydraulic system 4, an air supply system 5 and a drilling arm 6. The drill arm 6 is a straight arm, and the joint between the drill arm 6 and the drill frame 2 is provided with a drill frame lift compensation cylinder 22. The drill frame lift compensation cylinder 22 can lift the drill frame 2 to three to four meters, and can Boreholes are drilled in water and sand above three meters. The drilling arm 6 has a large rotation range and a wide construction range. The drilling tool includes a main drill rod 8, a drill bit 9 and a hammer 10. Inverter valve 11, impactor 10 is equipped with a stamping hammer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com