Method for calibrating numerical simulation results of inner flow field in centrifugal pump

A numerical simulation, internal flow field technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve the problems of high price, low specific speed, and the difficulty of transparent materials to withstand large pump stress, and achieve short cycle times. , Low experimental cost, avoid the effect of reopening the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

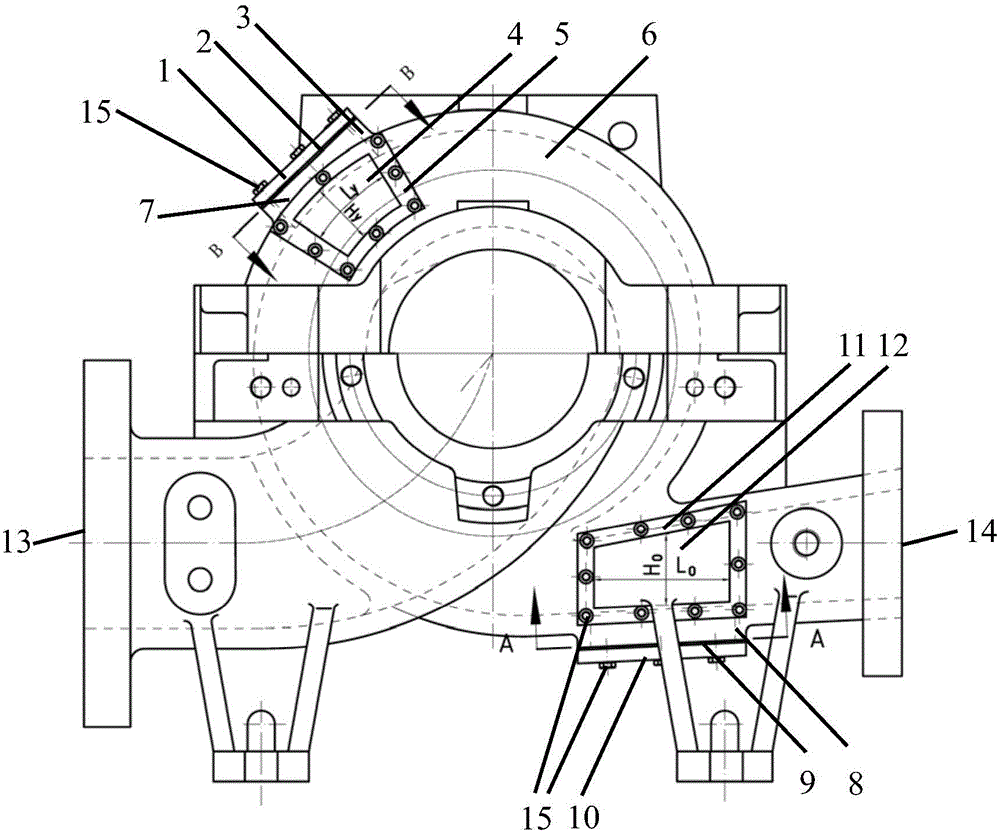

[0037] The present invention will be further explained below with reference to the drawings and examples.

[0038] Such as Figure 1-3 As shown, taking a double-suction centrifugal pump as an example, the specific implementation of the present invention is:

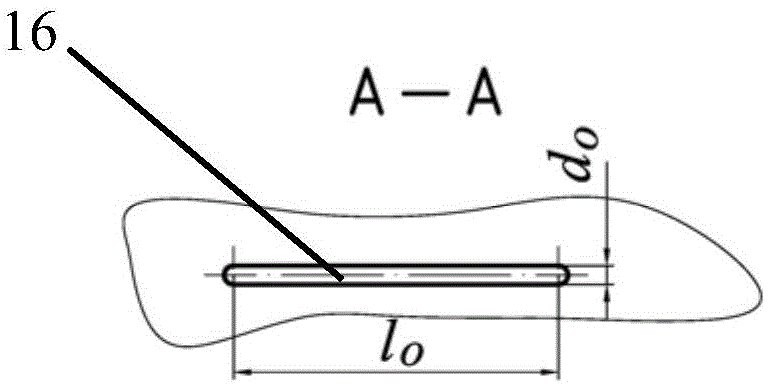

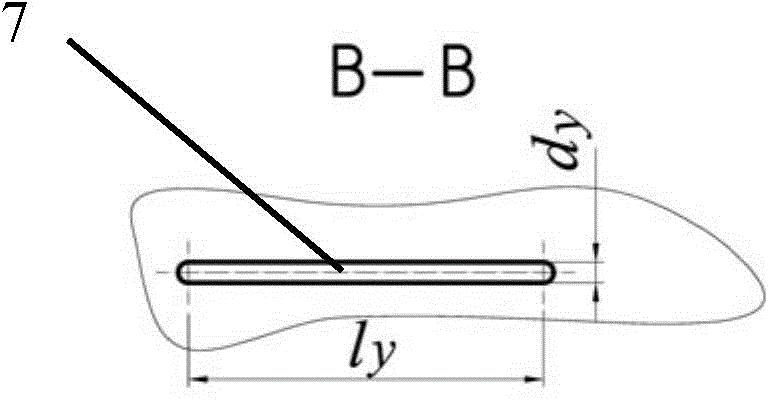

[0039] First of all, the partial mechanical modification of the prototype pump body of the double-suction centrifugal pump is carried out to meet the requirements of PIV measurement and lay a good foundation for obtaining the flow field in the pump. The transformation means that there are 1~3 fan-shaped windows 4 approximately centered on the central axis of rotation of the impeller in the tip clearance of the pressurized water chamber of the volute of the centrifugal pump, and an approximately rectangular and rectangular window is opened on the upstream side of the outlet 14 of the pressurized water chamber. A window 12 that is close to parallel to the center rotation surface of the centrifugal pump impeller. The windows ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com