Multi-cylinder diesel engine crankshaft and manufacturing method thereof

A technology for diesel engines and crankshafts, applied in the fields of multi-cylinder diesel engine crankshafts and diesel engine crankshafts, it can solve the problems that are not conducive to lubricating oil film gaps and affect the establishment of oil films, and achieve the effects of reducing the total mass, ensuring the reliability of the crankshaft, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

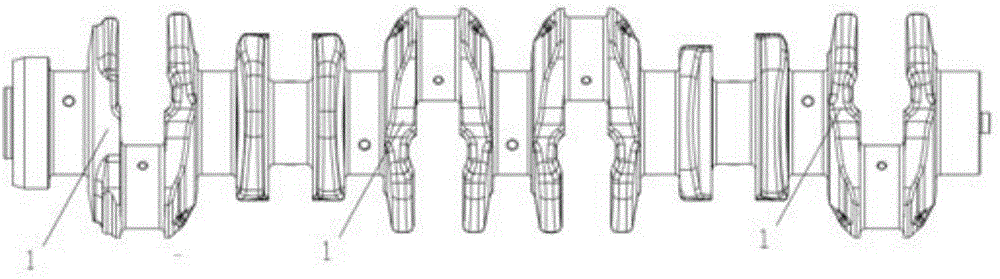

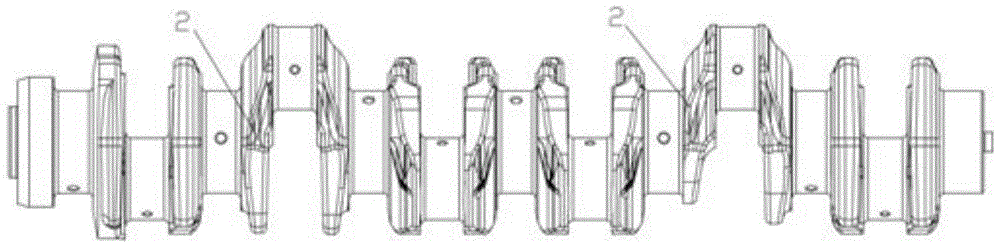

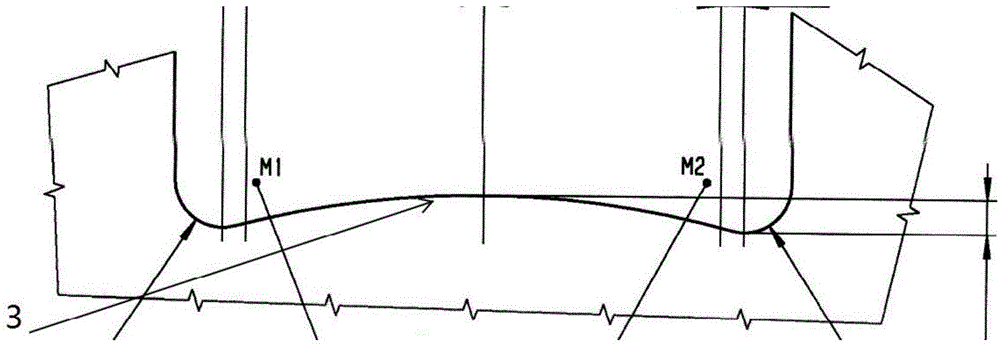

[0033] The crankshaft of a multi-cylinder diesel engine includes a main journal 5, a crank 8 and a connecting rod journal 6. The main journal 5 is connected with a number of parallel cranks 8, and the crank 8 and the crank 8 are connected through the connecting rod journal 6. The crank 8 is provided with a balance weight at the end far away from the center of the connecting rod journal. The balance weight is in a symmetrical arc shape, and the symmetrical center line of the balance weight is not on the same line as the axis of the crank main journal and the connecting rod journal, but forms a an acute angle.

[0034] The balance block is in a symmetrical arc shape, and the balance mass on each crank arm is different, and the mass-diameter product is distributed symmetrically or antisymmetrically, so as to ensure that the addition of all masses can make the crankshaft achieve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com