Thermo-mechanical coupling loading method for thermal strength tests

A technology of thermal coupling and thermal strength, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unsatisfactory heating belt, large influence of rubber, low thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

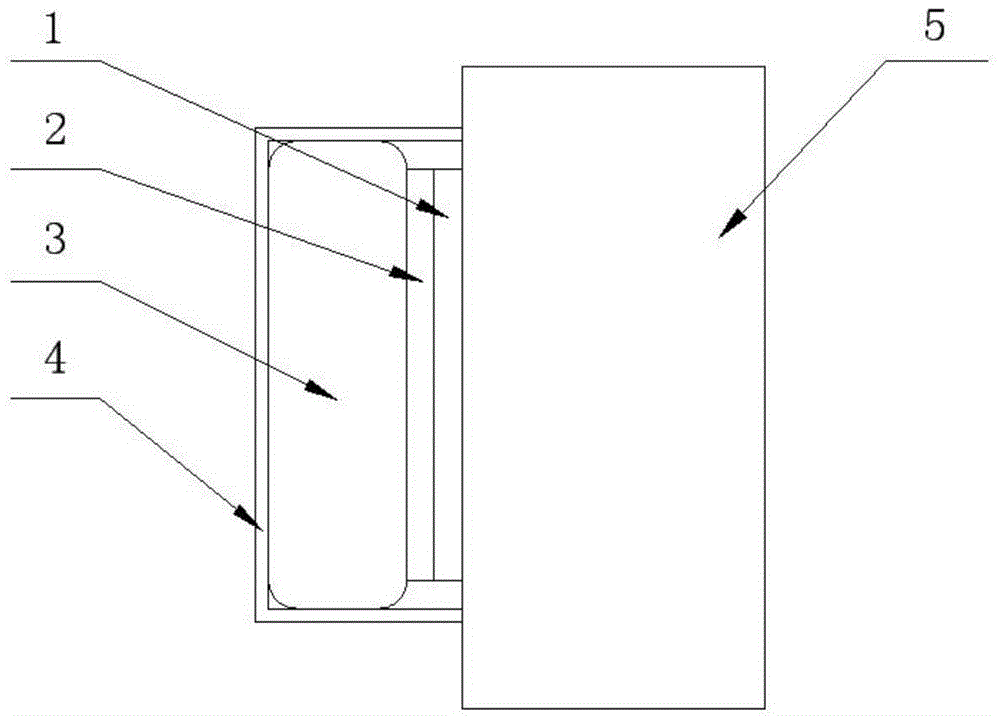

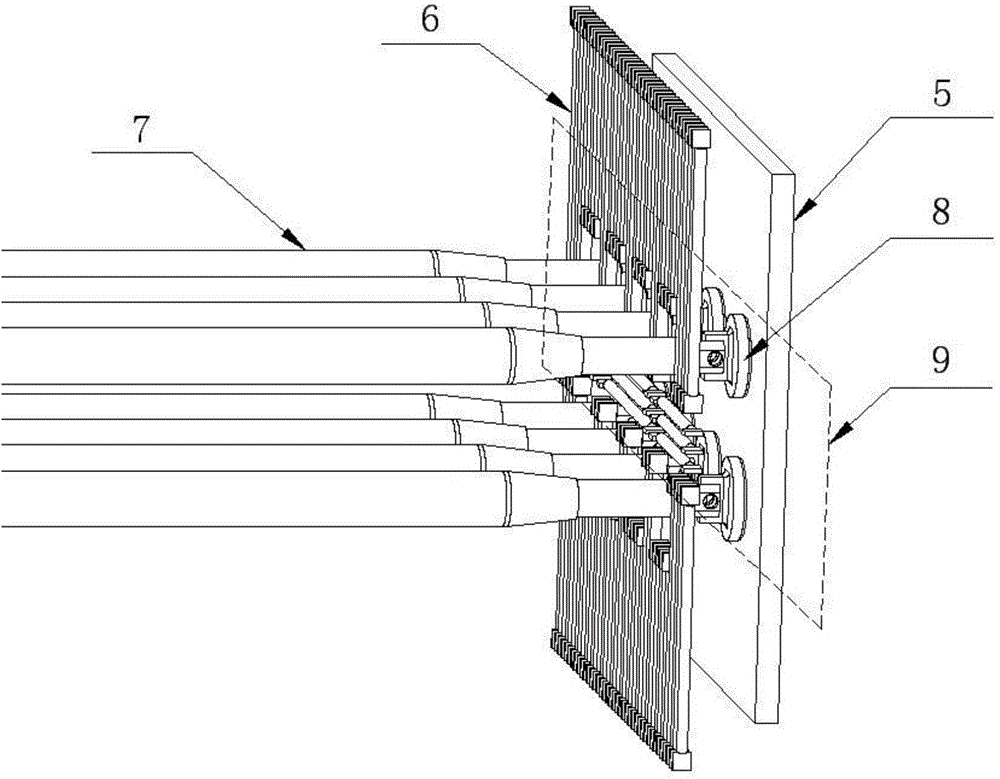

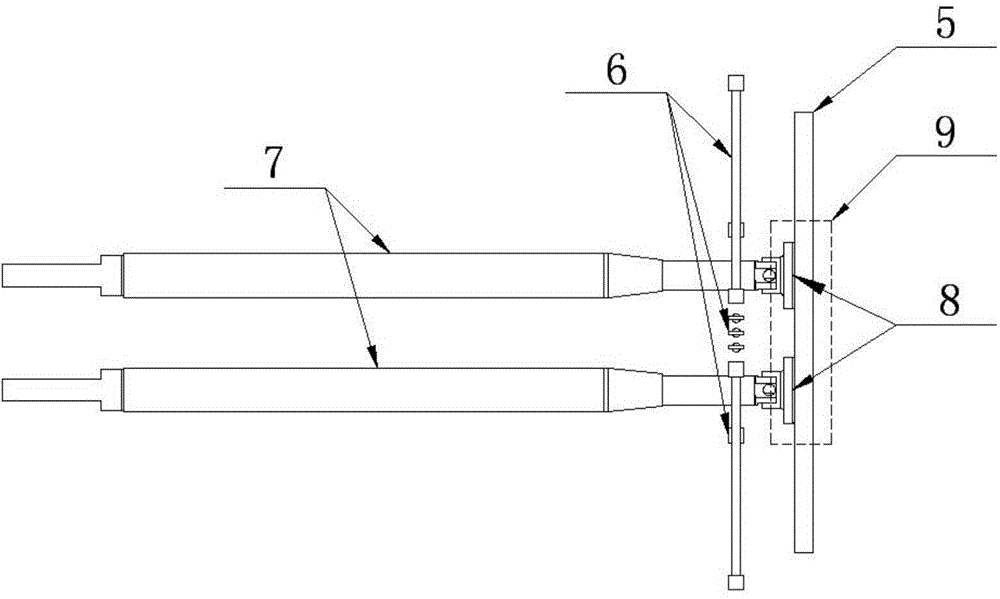

[0037] see figure 2 , image 3 and Figure 4 , which is a schematic diagram, a front view and a side view of the loading effect of the quartz lamp tube combined with the push rod pushing the loading block of the present invention, including the test piece 5, the quartz lamp tube 6, the push rod 7, the loading block 8 and the test piece loading area 9. The quartz lamp tubes 6 are arranged, and the quartz lamp tubes 6 are controlled in partitions. The arrangement range of the quartz lamp tubes is required to cover the edge of the test piece 5 and leave a space in the loading area 9 of the test piece. Connect the ejector rod 7 to the loading block 8, and pass through the area where the quartz lamp tubes 6 are arranged so that the loading block 8 is in uniform contact with the test piece 5. During the test, according to the load distribution requirements of the test piece loading area 9, the loading blocks are coordinated to load, so that the quartz lamps in each area under hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com