Atomic magnetic sensor for magnetometer and method of removing detection dead zones of magnetometer

A magnetic sensor and magnetometer technology, applied in magnetic resonance measurement and other directions, can solve the problems of inability to detect optical signals, affecting the size of detection signals, and inability to adapt to real-time detection of mobile platforms, so as to improve reliability and eliminate detection blind spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the present invention and cannot be understood as limiting the scope of protection of the present invention. Those skilled in the art can Some non-essential improvements and adjustments have been made to the present invention based on the above-mentioned content of the invention.

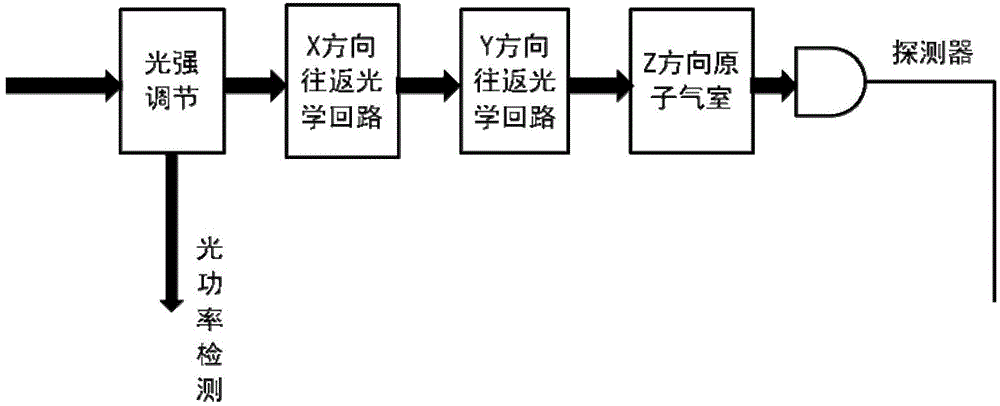

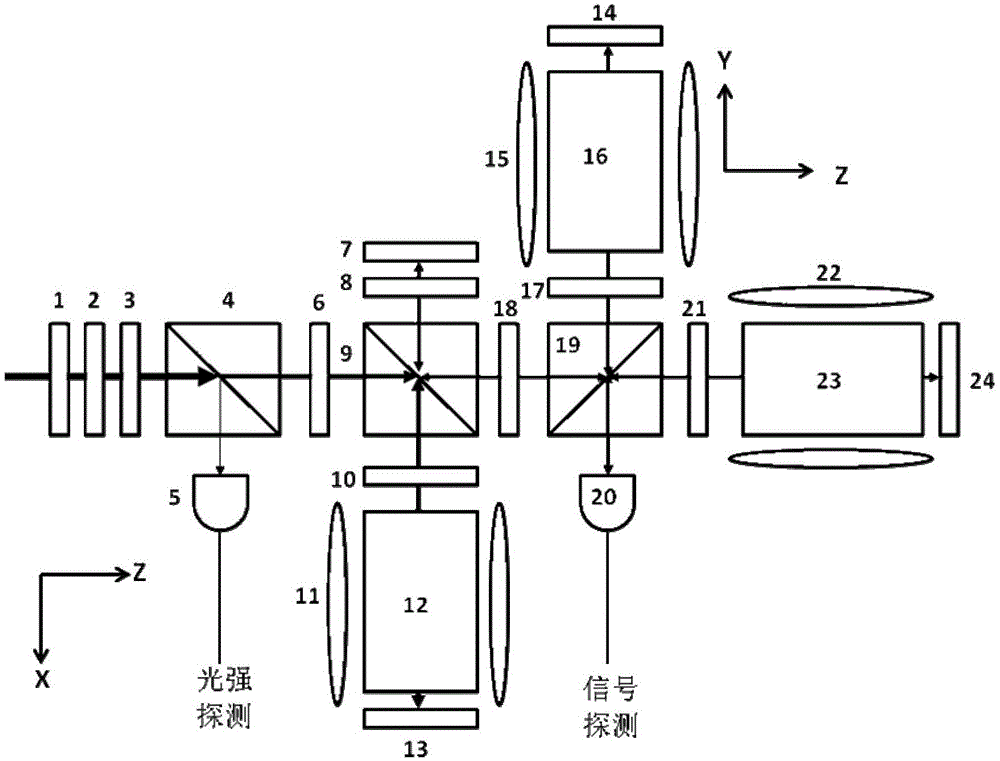

[0028] Such as figure 1 Shown is a schematic diagram of the main functional modules of the present invention, which includes a light intensity adjustment module without polarization influence. A part of the light is split and can be used to detect changes in optical power to stabilize the power of the laser, including X-direction round-trip optics The circuit forms the X-axis magnetic detection, including the Y-direction reciprocating optical circuit, forming the Y-axis magnetic detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com