Tail heat recycling rendering kettle

A technology of tail heat recovery and oil refining pot, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of low thermal efficiency and high energy consumption, and achieve the effect of improving utilization rate and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

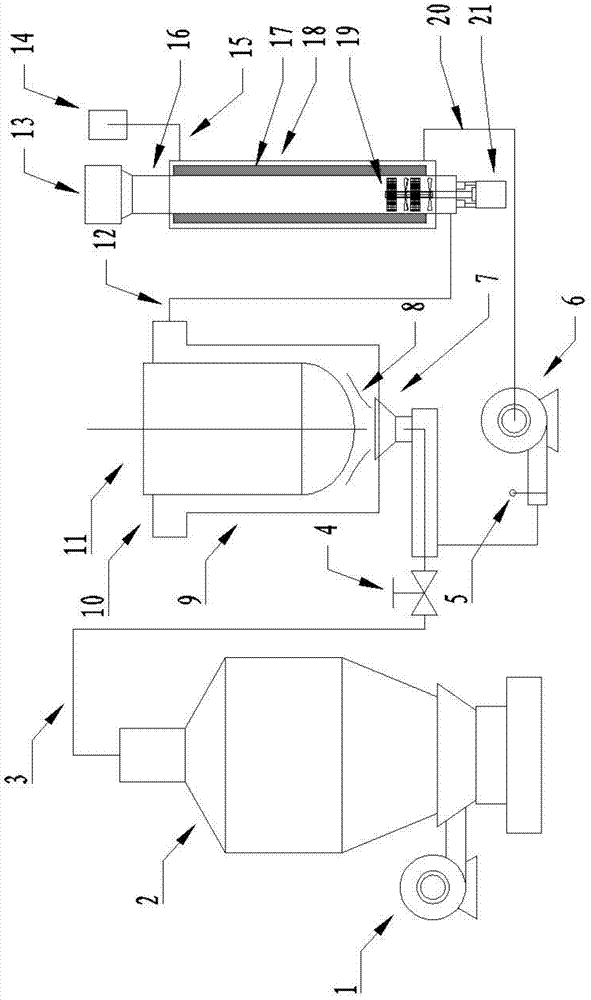

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

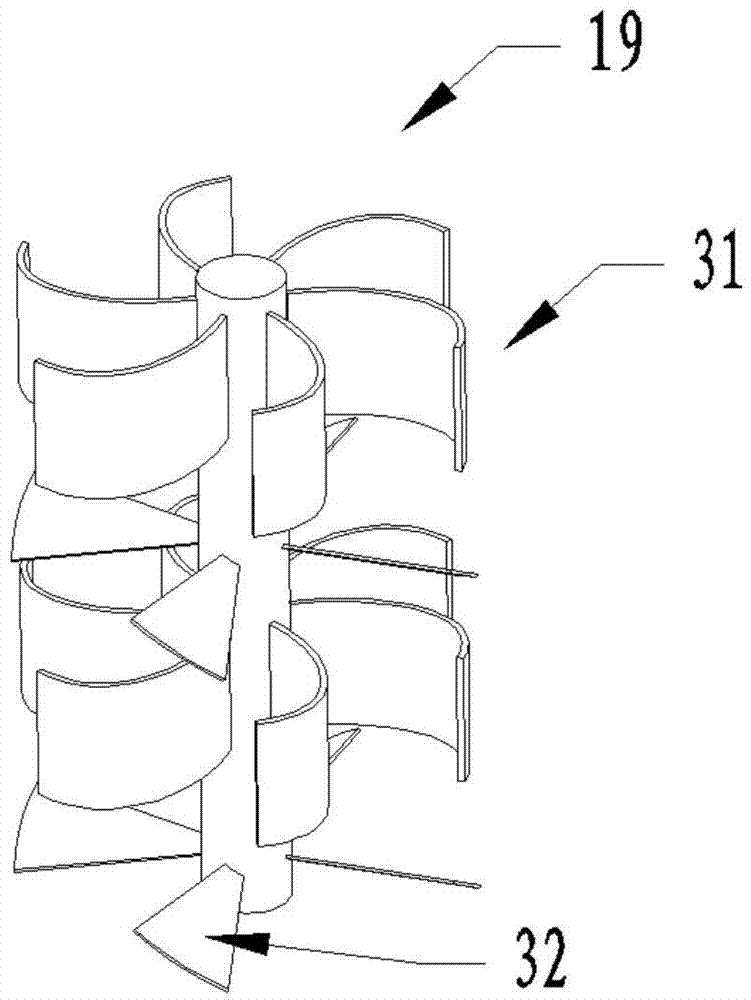

[0014] Such as figure 1 As shown, a tail heat recovery oil refining boiler includes a gas furnace blower 1, a gas furnace 2, and a pot body 11. The gas furnace blower 1 is connected to the gas furnace 2, and the gas furnace 2 is connected to the gas burner 7 through a gas pipe 3. The gas pipe 3 is provided with a gas control valve 4 for controlling gas in and out, a pot body 11 is disposed above the gas burner head 7, and a heat-insulating outer cylinder 9 is disposed on the periphery of the pot body 11. A gas collecting ring 10 is arranged on the top of the cylinder 9. The high-temperature exhaust gas collected by the gas collecting ring 10 is pumped by the rotor body 19 through the exhaust pipe 12 and enters the sleeve-type heat exchanger. The rotor body 19 is driven to rotate by the motor 21. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com