Preparation method and use of biocompatible temperature-sensitive gel microspheres

A biocompatible, temperature-sensitive gel technology, applied in the preparation of biocompatible temperature-sensitive gel microspheres and its application field, can solve problems such as cross-immunity, increase in raw material cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of biocompatible thermosensitive microspheres of the present invention:

[0022] First disperse 12-hydroxystearic acid (HSA) gel factor with a mass fraction of 1-10wt% into commercially available soybean oil or peanut oil, take 1-5ml of the above mixed solution into 5-30ml of pure water, and then put The GEX600 ultrasonic probe of Sonics&Materials Company is placed at the water-oil interface, 20-50kHz, 30-600W ultrasonic for 3-10min to obtain nano-microscale microspheres suspended in water.

Embodiment 2

[0024] Measurement of the performance of the biocompatible thermosensitive microspheres of the present invention:

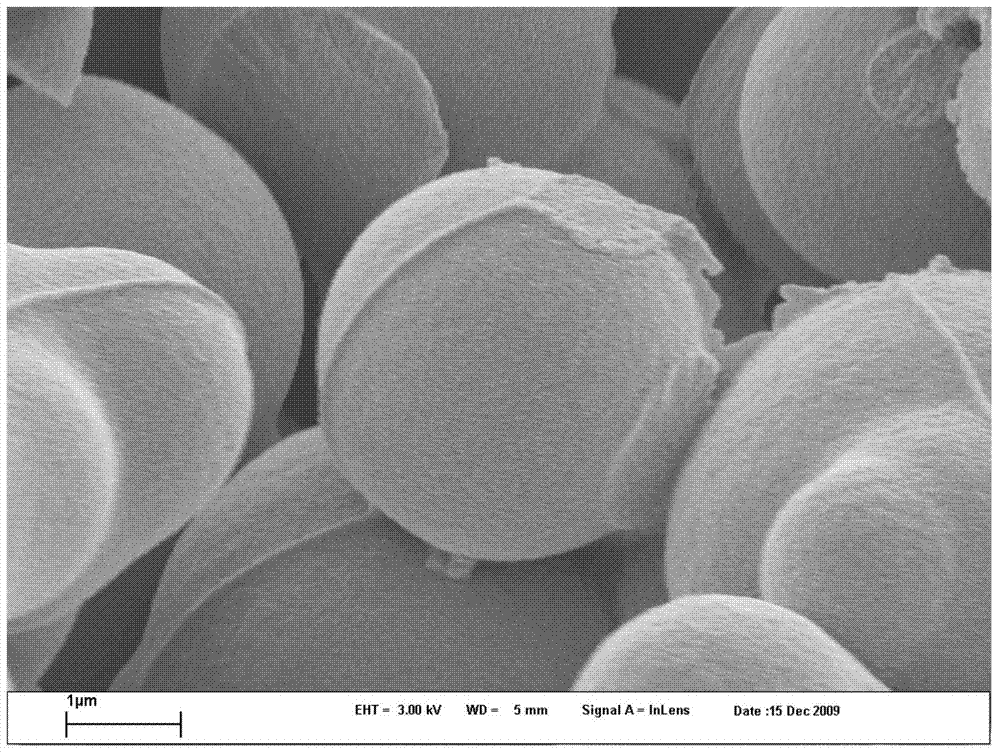

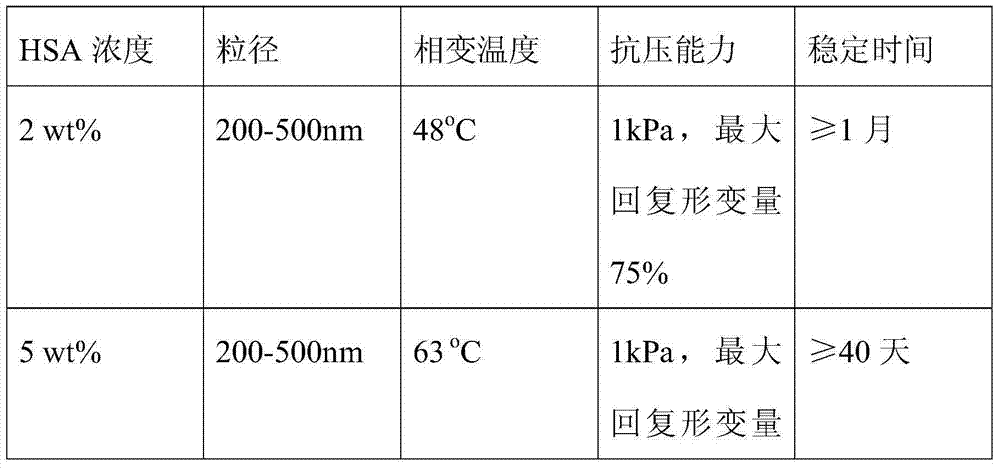

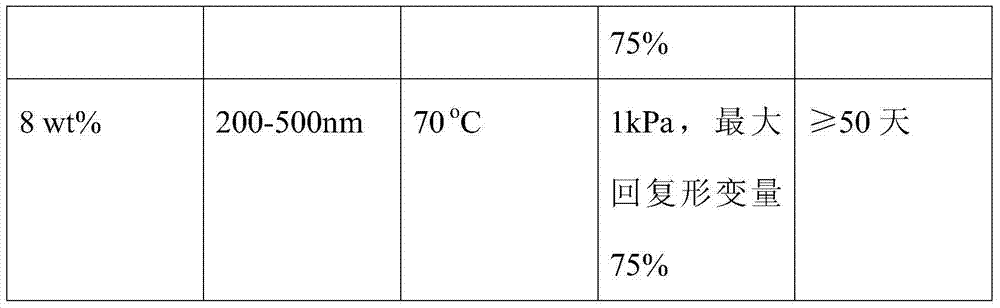

[0025] Microsphere properties mainly include its physical properties and its performance as a carrier. Among them, physical properties include microsphere particle size, phase transition temperature (ie temperature sensitivity), mechanical properties, structural stability, etc.; they are detected by particle size analyzer, thermometer, atomic force microscope and scanning electron microscope. Taking the microspheres prepared by ultrasonic frequency-intensity of 25Hz-50W / cm2 as an example, the properties of the microspheres change with the concentration adjustment as shown in the following table:

[0026]

[0027]

[0028] As shown in the table, the phase transition temperature and structural stability can be achieved by adjusting the concentration of HSA in the preparation process

[0029] The particle size control of microspheres can be realized by adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com