Catalyst for preparation of aldehyde through heterogeneous catalysis of fat primary alcohol dehydrogenation

A heterogeneous catalysis and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, preparation of carbon-based compounds, etc. There are 17% and other problems, to achieve the effect of high selectivity, simple recycling and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

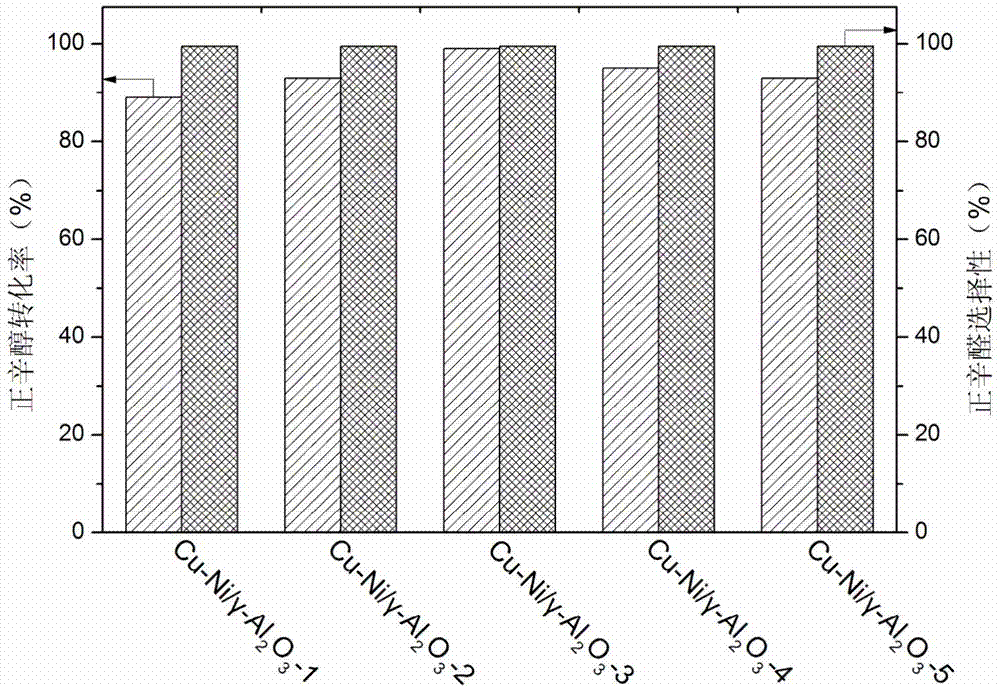

[0020] Example 1: Cu-Ni / γ-Al 2 o 3 Preparation of a series of catalysts

[0021] According to the mass content of Cu shown in Table 1, a copper nitrate solution with a suitable concentration was prepared, and the pH of the copper nitrate solution was adjusted to 9 with ammonia water. Put the above solution in an ice-water bath under stirring conditions, disperse 2g of activated alumina in the copper nitrate solution and stir for 3h, then dilute with a large amount of water, finally, filter and wash three times, dry at 80°C for 10h, and roast at 400°C for 6h , to obtain the catalyst precursor Cu / γ-Al 2 o 3 .

[0022] According to the mass ratio of Cu and Ni shown in Table 1, prepare a nickel nitrate solution with a suitable concentration, take 2g Cu / γ-Al 2 o 3 Add it and stir for 3h, dry at 80°C for 10h, and bake at 400°C for 6h. The obtained catalyst was reduced in a hydrogen atmosphere at 500° C. for 5 h before use.

[0023] Table 1

[0024]

Embodiment 2

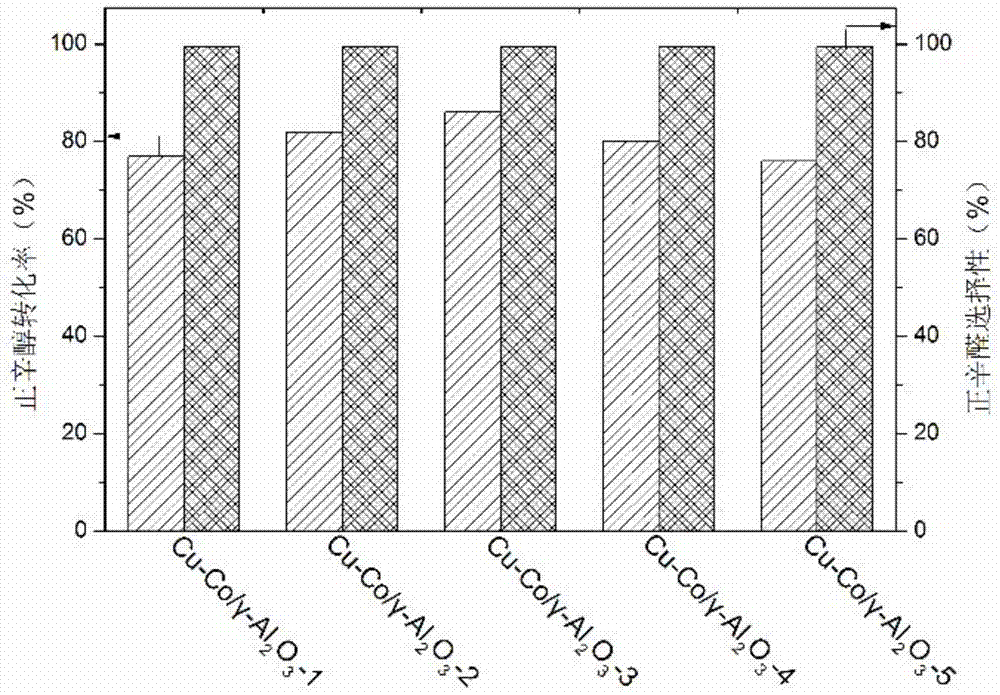

[0025] Example 2: Cu-Co / γ-Al 2 o 3 Preparation of a series of catalysts

[0026] According to the mass content of Cu shown in Table 2, a copper nitrate solution with a suitable concentration was prepared, and the pH of the copper nitrate solution was adjusted to 9 with ammonia water. Put the above solution in an ice-water bath under stirring conditions, disperse 2g of activated alumina in the copper nitrate solution and stir for 3h, then dilute with a large amount of water, finally, filter and wash three times, dry at 80°C for 10h, and roast at 400°C for 6h , to obtain the catalyst precursor Cu / γ-Al 2 o 3 .

[0027] According to the mass ratio of Cu and Co shown in Table 2, prepare a cobalt nitrate solution with a suitable concentration, take 2g Cu / γ-Al 2 o 3 Add it and stir for 3h, dry at 80°C for 10h, and bake at 400°C for 6h. The obtained catalyst was reduced in a hydrogen atmosphere at 500° C. for 5 h before use.

[0028] Table 2

[0029]

Embodiment 3

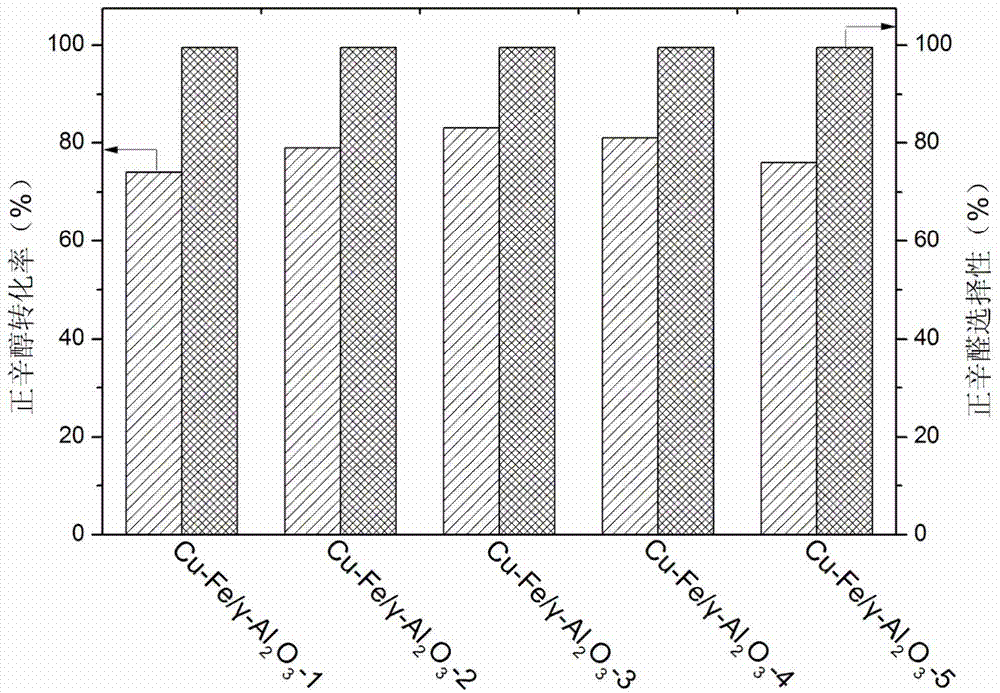

[0030] Example 3: Cu-Mn / γ-Al 2 o 3 Preparation of a series of catalysts

[0031] According to the mass content of Cu shown in Table 3, a copper nitrate solution with a suitable concentration was prepared, and the pH of the copper nitrate solution was adjusted to 9 with ammonia water. Put the above solution in an ice-water bath under stirring conditions, disperse 2g of activated alumina in the copper nitrate solution and stir for 3h, then dilute with a large amount of water, finally, filter and wash three times, dry at 80°C for 10h, and roast at 400°C for 6h , to obtain the catalyst precursor Cu / γ-Al 2 o 3 .

[0032] According to the mass ratio of Cu and Mn shown in Table 3, prepare a manganese nitrate solution with a suitable concentration, take 2g Cu / γ-Al 2 o 3 Add it and stir for 3h, dry at 80°C for 10h, and bake at 400°C for 6h. The obtained catalyst was reduced in a hydrogen atmosphere at 500° C. for 5 h before use.

[0033] table 3

[0034]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap