Dislocation wire lap joint point device

A technology for lap joints and wire rods, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of large fluctuations in the structure and performance of wire rods, poor cooling speed, and affecting quality, so as to solve the problem of large fluctuations in strength and improve quality , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

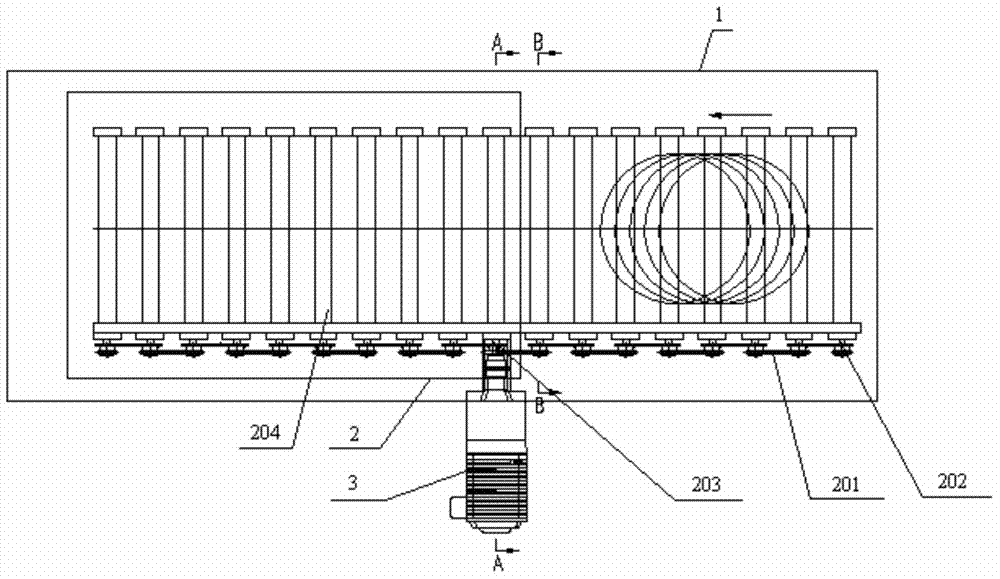

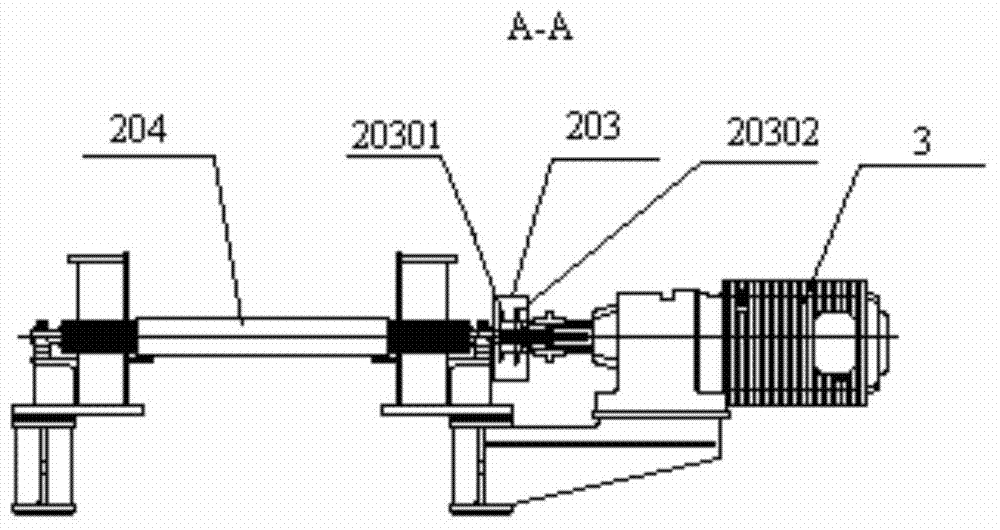

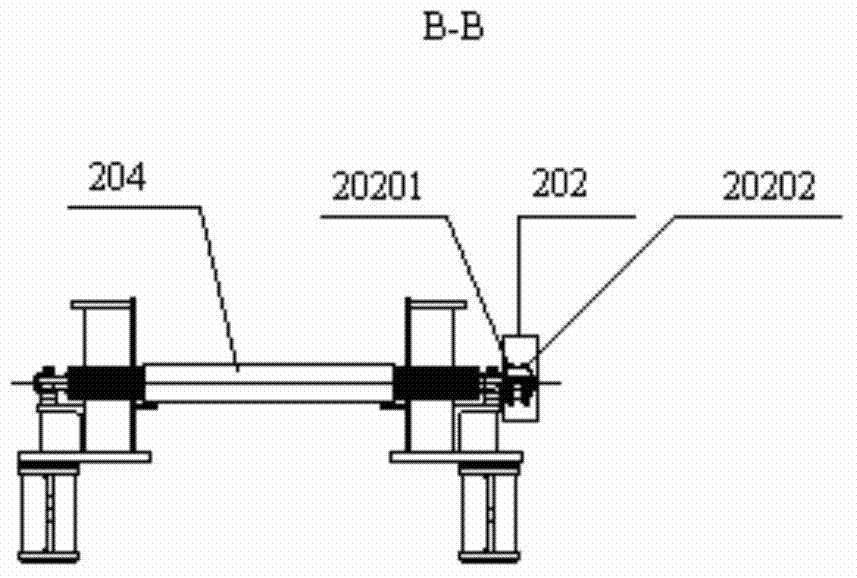

[0028] see Figure 1-3 , is a schematic diagram of the structure of the staggered wire overlapping point device provided in Embodiment 1 of the present invention.

[0029] A staggered wire overlap point device, comprising at least two adjacent single-stage roller table units 1; the single-stage roller table unit 1 includes at least one set of roller units 2, a transmission motor 3 that provides power to the roller units 2, and other conveying Rollers 204, wherein, the more roller units 2 are in quantity, the more frequent and easier the movement is; the roller unit 2 includes a transmission chain 201, a constant speed sprocket set 202, a variable speed sprocket set 203 and at least three rollers 204; on one roller 204 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com