Method for improving coercive force of neodymium iron boron quick-quenching nanocrystalline magnetic powder

A nanocrystalline, NdFeB technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems such as the inability to effectively improve the coercive force of magnets, waste of resources, and poor results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

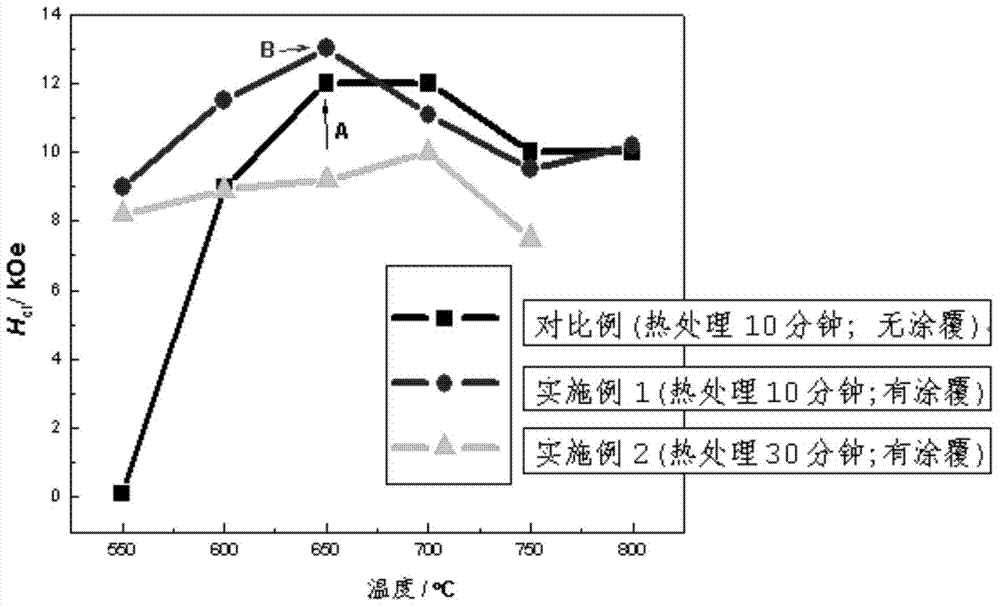

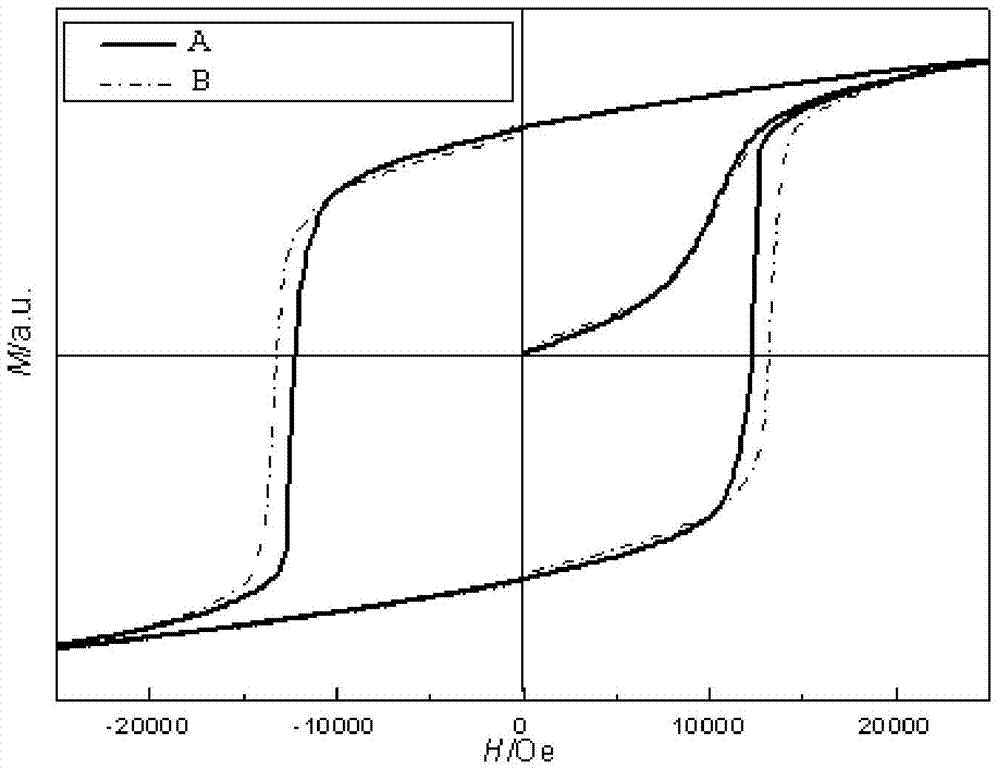

Embodiment 1

[0032] The nominal composition (atomic percentage) of the low melting point alloy used is Nd 70 Cu 30 , Alloy ingots were prepared by vacuum arc melting. The protective gas is high-purity argon, and the front and back are smelted four times.

[0033] The alloy ingot is put into a disc mill for disc grinding for 10 minutes to obtain alloy powder.

[0034] The disc-milled alloy powder was put into a gasoline-protected planetary ball mill jar and ball-milled for 100 minutes to obtain alloy powder, which was then vacuum-dried.

[0035] Mix the dried alloy powder with absolute ethanol at a mixing weight ratio of 1:4, and stir thoroughly to form a suspension.

[0036] The nominal composition (atomic percentage) of NdFeB quenching powder is Nd 11.8 Dy 0.5 Fe 79.7 Zr 0.8 Nb 0.8 Cu 0.4 B 6 , with an average particle size of 300 microns. Mix the NdFeB quick-quenching powder with the above-mentioned suspension, and stir thoroughly to make the NdFeB quick-quenching powder fully...

Embodiment 2

[0040] The nominal composition (atomic percentage) of the low melting point alloy used is Nd 70 Cu 30 , the alloy ingot was prepared by vacuum arc melting, the protective gas was high-purity argon, and the reverse side was smelted four times.

[0041] Put the alloy ingot into the disc mill, and disc mill for 10 minutes.

[0042] The disc-milled alloy powder was ball-milled for 100 minutes in a gasoline-protected planetary ball mill jar to obtain alloy powder, and then the powder was dried.

[0043] Mix the dried powder with absolute ethanol at a mixing weight ratio of 1:4, stir well to form a suspension.

[0044] Mix the same NdFeB quick-quenching powder as in Example 1 with the suspension, and stir thoroughly to make the NdFeB quick-quenching powder fully contact with the particles in the suspension. Then use a 300-mesh sieve to filter out the NdFeB quick-quenching powder, and dry it in a vacuum environment.

[0045]The above-mentioned dried NdFeB quick-quenching powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com