Bi-layer structure material of CoPt/Ta vertical magnetic film and preparation method thereof

A double-layer structure and vertical magnetization technology, applied in the field of information storage, can solve the problems of reduced magnetic anisotropy, achieve the effects of improving coercive force, high chemical properties, and weakening exchange coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In the preparation method provided by the invention, following preferred processing parameters can be adopted:

[0041] The power of the sputtering Co target and the CoPt alloy target is 15W-200W (a further preferred value is 20W), and the sputtering Ar pressure is 0.45Pa-1.0Pa (a further preferred value is 0.5Pa).

[0042] The sputtering Ta target power is 15W-200W (more preferably 25W), and the sputtering Ar gas pressure is 0.45Pa-1.0Pa (more preferably 0.5Pa).

[0043] The annealing temperature is 600°C-850°C, and further, the annealing time of CoPt / Ta and CoPt is 10min-1h.

[0044] The CoPt / Ta structure of the present invention and the preparation method using Ta as the CoPt protective layer can adopt methods such as sputtering, chemical vapor deposition, evaporation, atomic layer deposition, metal-organic thermal decomposition, or laser-assisted deposition. any one of the preparation methods.

Embodiment 1

[0046] In this embodiment, the magnetron sputtering method is used to prepare CoPt / Ta and CoPt magnetic thin films.

[0047] The substrate is Si(100), and a CoPt alloy target with a diameter of 100 mm and a thickness of 5 mm (atomic ratio Co:Pt=1:1) is prepared, and the purity of the target is 99.999% (atomic percentage). Using the method of magnetron sputtering, Ar gas with a purity of 99.999% is introduced during sputtering.

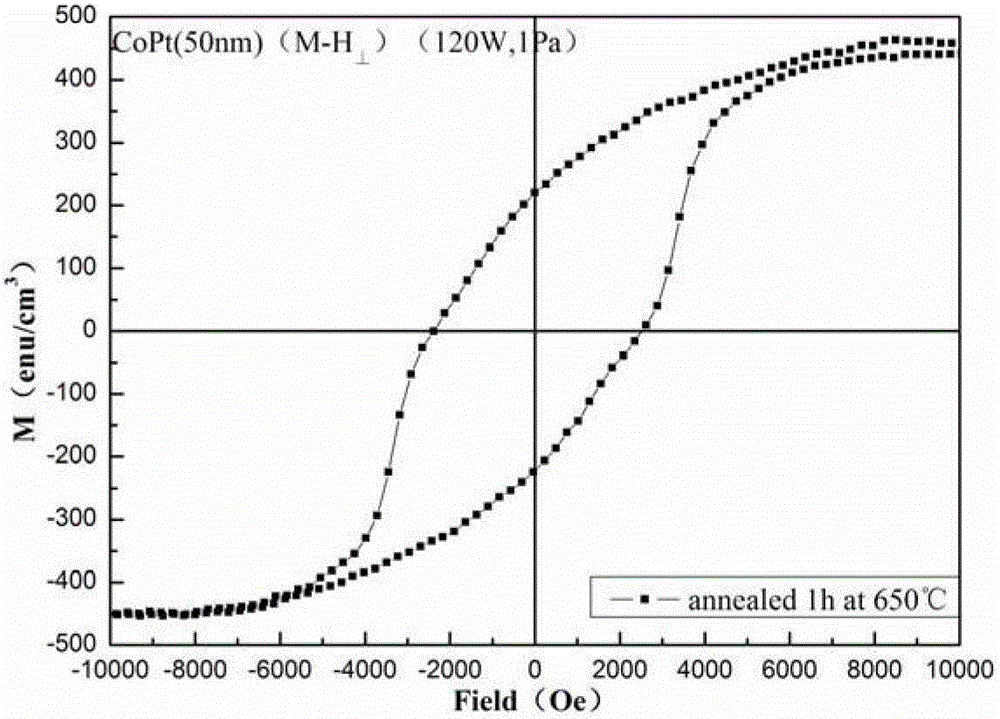

[0048] The specific process parameters are as follows: CoPt alloy target adopts DC power supply, sputtering power is 120W; sputtering Ar pressure is 1Pa; pre-sputter for 1 hour before each sputtering to ensure that the oxide layer on the surface of CoPt alloy target is completely removed. The thickness of the film was measured by a step meter to prepare a 50nm CoPt magnetic film. The vertical magnetic properties of CoPt (50nm) thin films were tested by VSM. figure 2 From the vertical magnetization curve of CoPt shown, it can be seen that the vertica...

Embodiment 2

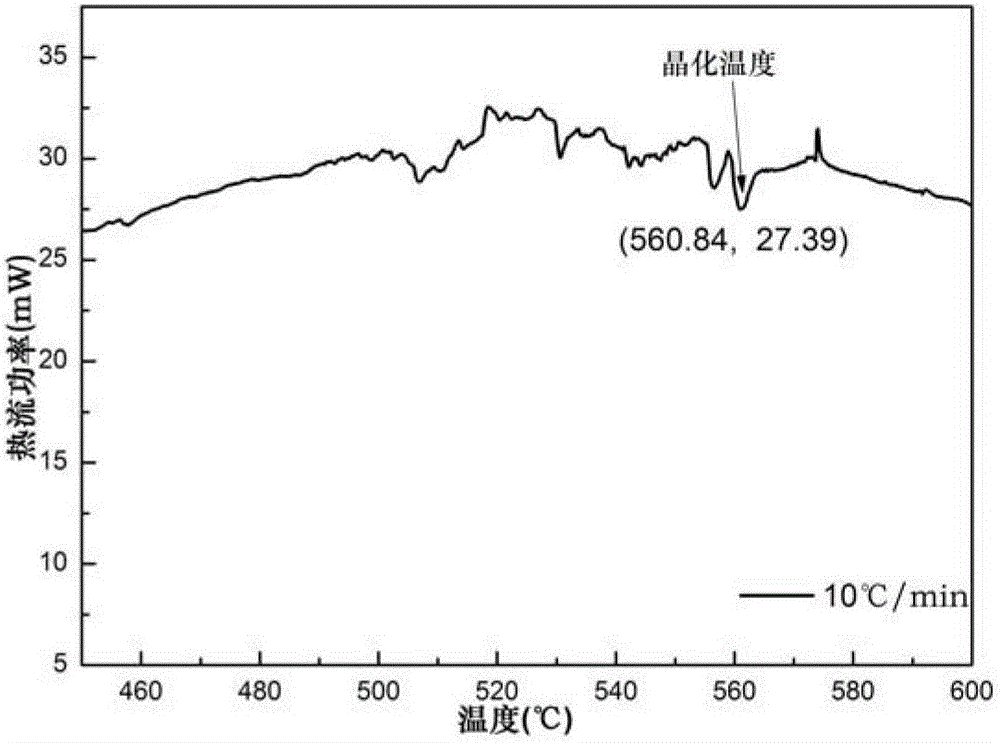

[0050] The phase transition temperature of CoPt thin film was investigated.

[0051] The substrate is Si(100), and a Co target with a diameter of 100 mm and a thickness of 5 mm is prepared. The purity of the target is 99.999% (atomic percentage). The Pt sheet with a size of 2*10 mm is evenly pasted on the Co target. The atomic ratio of Co to Pt was adjusted to be 1:1 by changing the number of Pt flakes. Then, the method of magnetron sputtering is used, and Ar gas with a purity of 99.999% is introduced during sputtering.

[0052] The specific process parameters are as follows: the Co target adopts a DC power supply, and the sputtering power is 20W; the sputtering Ar pressure is 0.5Pa; each sputtering is pre-sputtered for 1 hour to ensure that the oxide layer on the surface of the Co target is completely removed. CoPt magnetic films with different atomic ratios can be obtained by changing the number of Pt sheets attached to the Co target each time. By analyzing with the energy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com