Large-scale marine pipeline initial point recognition and location method and system based on CCD

A positioning method and starting point technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not suitable for large-scale pipeline welding, rare research and application, and not suitable for precise positioning, etc. Improve the level of automation and welding efficiency, reduce manual positioning errors, and save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

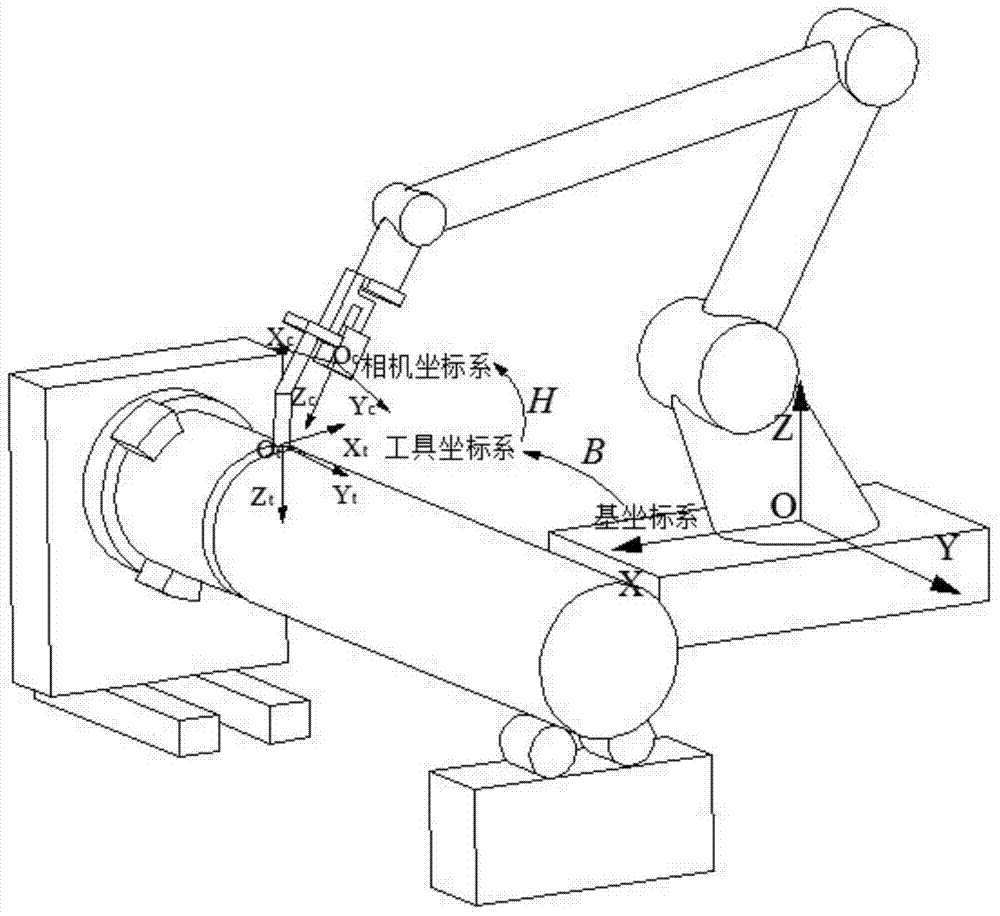

[0031] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings, but the implementation of the present invention is not limited thereto.

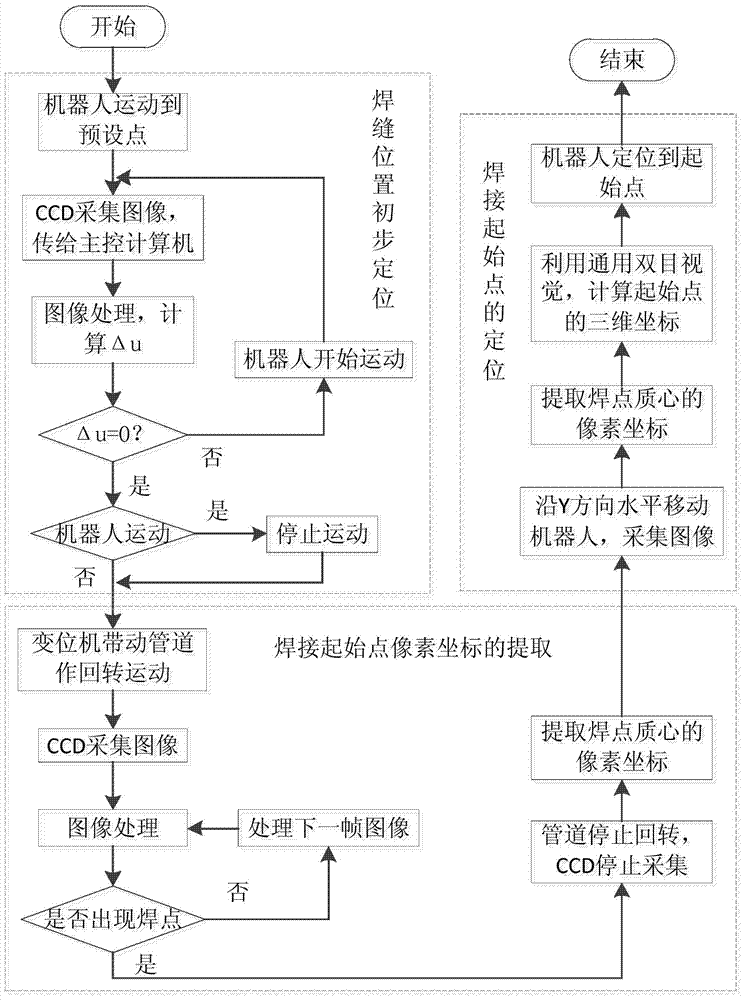

[0032] Please refer to figure 1 As shown, the present invention is based on the CCD large-scale marine pipeline welding starting point identification and positioning method, which includes the following steps:

[0033] Step 1: Preliminary positioning of the weld position

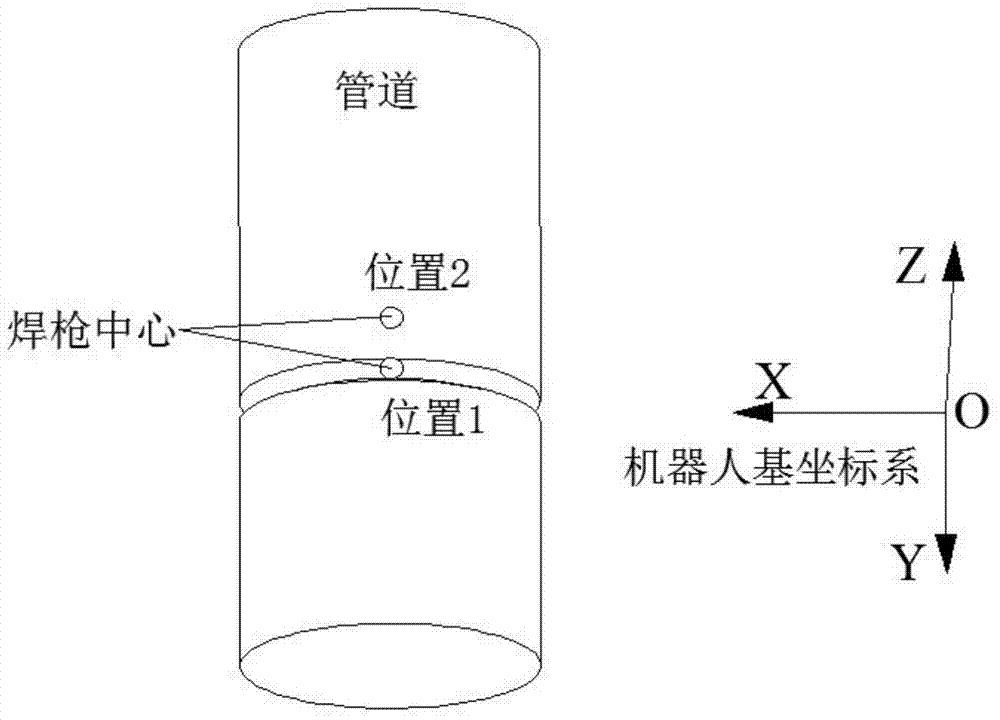

[0034] (a) Keep the pipeline to be welded still, the welding robot moves to the preset position, and the weld seam image of the pipeline to be welded is collected by the CCD industrial digital camera, and the main control computer receives the picture through the USB line and performs image processing. Preliminary Identify the weld, extract the center line of the weld, sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com