Precombustion tar-removal coal gas preparation method

A technology of coal gas and tar, which is applied in the field of gas preparation for pre-burning tar, can solve the problems of toxic phenol water and environmental pollution, and achieve the effects of prolonging the reaction time, avoiding environmental pollution, and avoiding phenol water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

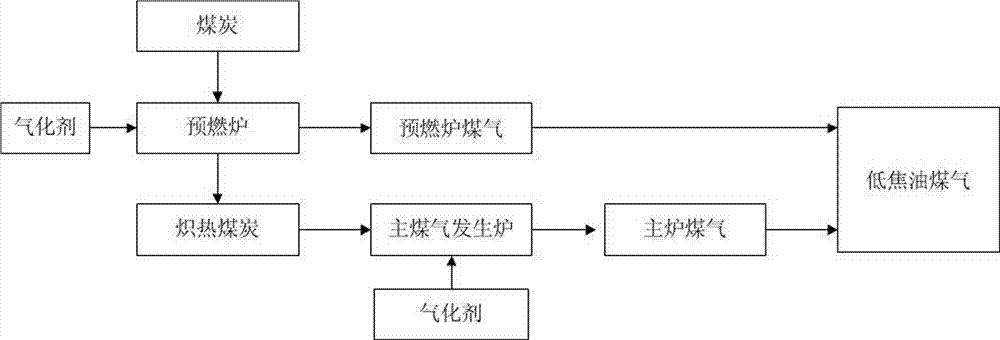

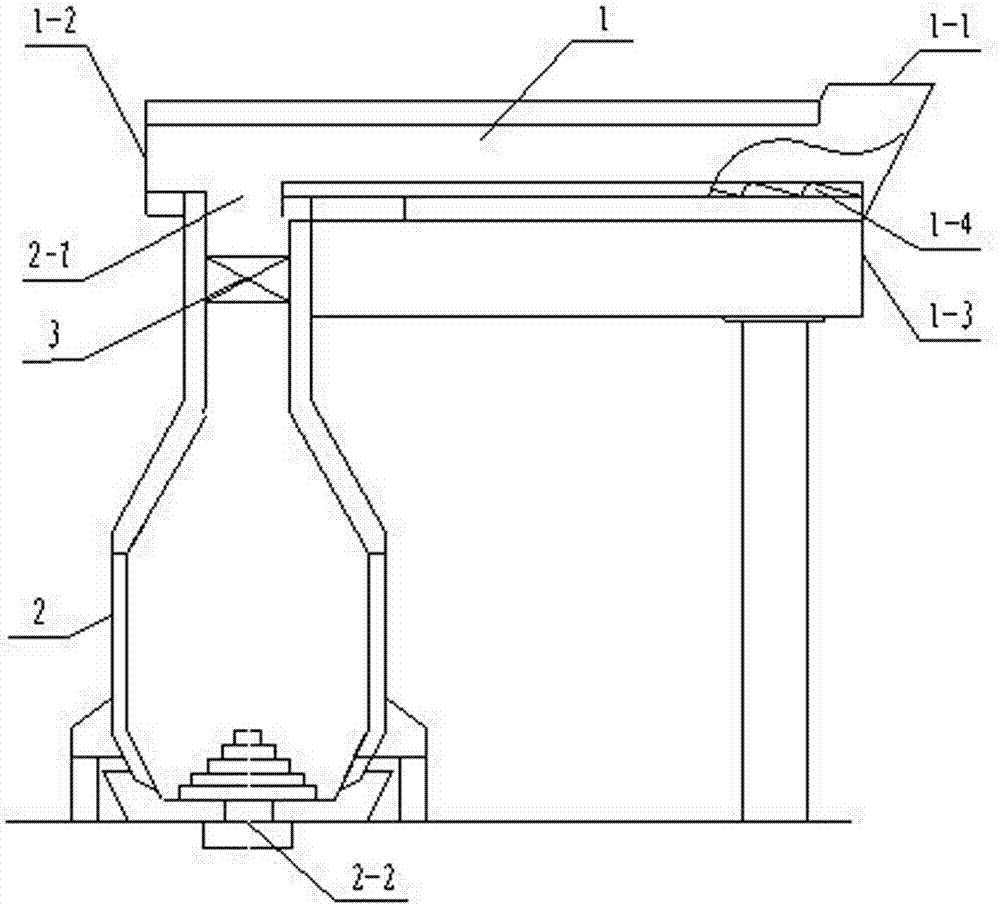

[0018] refer to Figure 1-2 In Example 1, coal is added into the pre-combustion furnace 1 from the coal inlet 1-1 of the pre-combustion furnace, and the furnace flame temperature of the pre-combustion furnace 1 is above 1300 ° C. 1. Air and a certain amount of water vapor are introduced into the chamber, and their functions are to support combustion and cool down the grate respectively, and part of the water vapor also acts as a gasifying agent. Under the high temperature condition above 1300°C in the pre-combustion furnace 1, macromolecules of volatile phenol (tar) are decomposed, and some of them are oxidized to release heat and generate CO 2 And water, so the tar component in the pre-combustion furnace gas is greatly reduced. Use the grate 1-4 in the pre-combustion furnace (it can be a reciprocating grate or a chain grate) to push the hot coal 3 in the pre-combustion furnace 1 into the main gas generator 2, and the hot coal 3 is in the main gas generator 2 Inner stacking ...

Embodiment 2

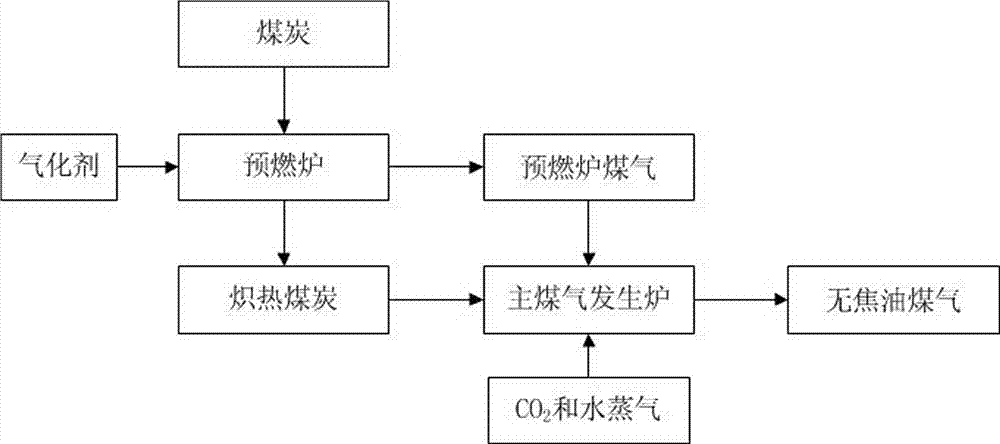

[0020] refer to Figure 3-4 In Example 2, coal is fed into the pre-combustion furnace 1 from the coal inlet 1-1 of the pre-combustion furnace. Air and an appropriate amount of water vapor are fed in, and their functions are to support combustion and cool down the grate, and part of the water vapor also acts as a gasifying agent. Under the high temperature condition above 1300°C in the pre-combustion furnace 1, macromolecules of volatile phenol (tar) are decomposed, and some of them are oxidized to release heat and generate CO 2 And water, so the pre-combustion furnace gas contains only a very small amount of tar components. Utilize the grate 1-4 in the pre-combustion furnace (it can be a reciprocating grate or a chain grate) to push the hot coal 3 in the pre-combustion furnace 1 into the main gas generator 2 through the double-layer sealed material door 4, and the hot coal 3 is piled up in the main gasifier 2 and forms a full-height carbon layer space thermal field. The dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com