A multi-stage filter type natural gas compressor

A technology for natural gas and compressors, which is applied in the field of multi-stage filter natural gas compressors. It can solve the problems of complex structure of filter devices, inability to ensure the purity of compressed natural gas, and difficult cleaning, so as to save labor costs, save space, and save equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

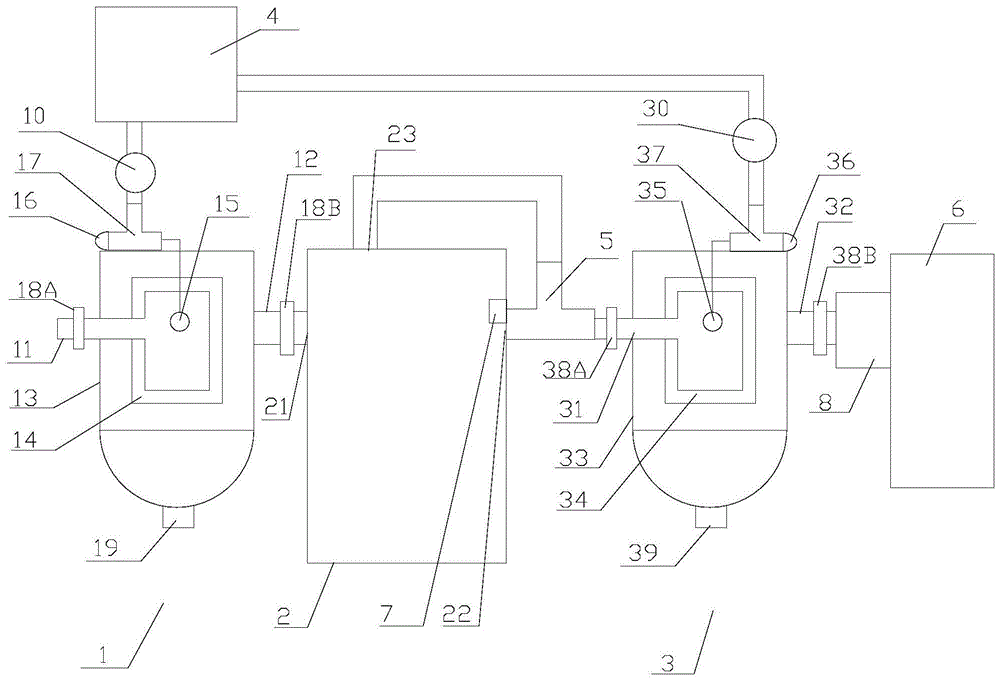

[0023] refer to figure 1 , A multi-stage filter type natural gas compressor proposed by the present invention includes: a first filter device 1, a cylinder 2, a second filter device 3, a cleaning liquid storage tank 4, a first three-way valve 5, a gas storage device 6 and control module.

[0024] The first filter device 1 includes a first suction pump 10, a first input pipe 11, a first output pipe 12, a first housing 13, a first filter element 14, a first spherical nozzle 15, a first fan 16 and a first three Through valve 17.

[0025] The first filter element 14 is installed in the cavity in the first shell 13 , the first input pipe 11 passes through the first shell 13 and communicates with the first filter element 14 , and the first output pipe 12 communicates with the cavity in the first shell 13 . The cavities are connected, the first input pipe 11 and the first output pipe 12 are respectively installed with a first shut-off valve 18A and a second shut-off valve 18B, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com