Rubber thermo-oxidative aging dynamic testing device and method for testing thermo-oxidation absorption curve

A technology of thermo-oxidative aging and testing equipment, which is applied in the direction of measuring equipment, scientific instruments, instruments, etc., can solve the problems such as the lack of uniform rubber thermal oxidation resistance, improve the efficiency of the test and the accuracy of the test results, improve the accuracy and objectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

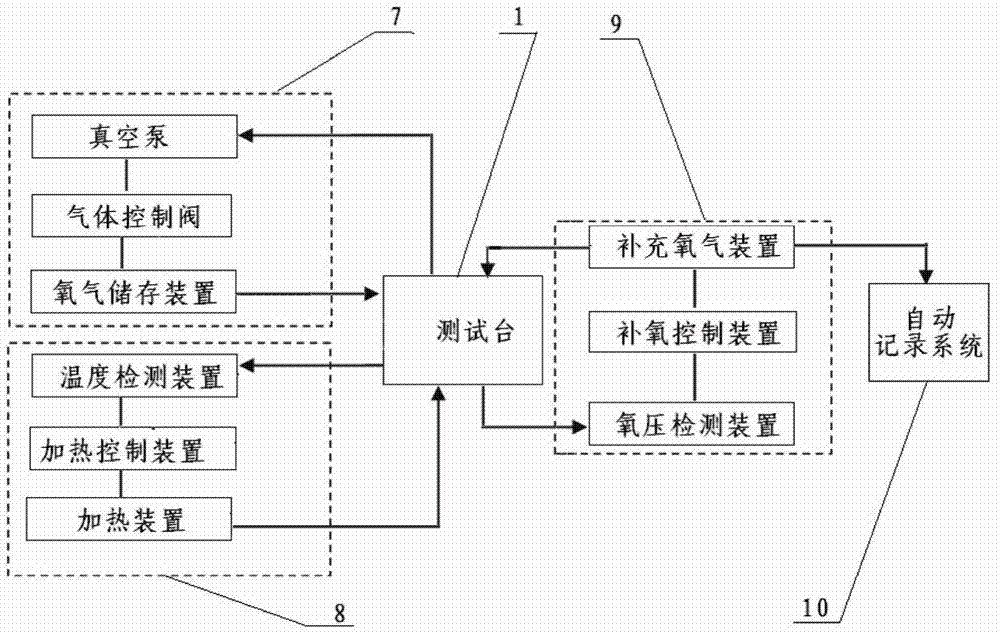

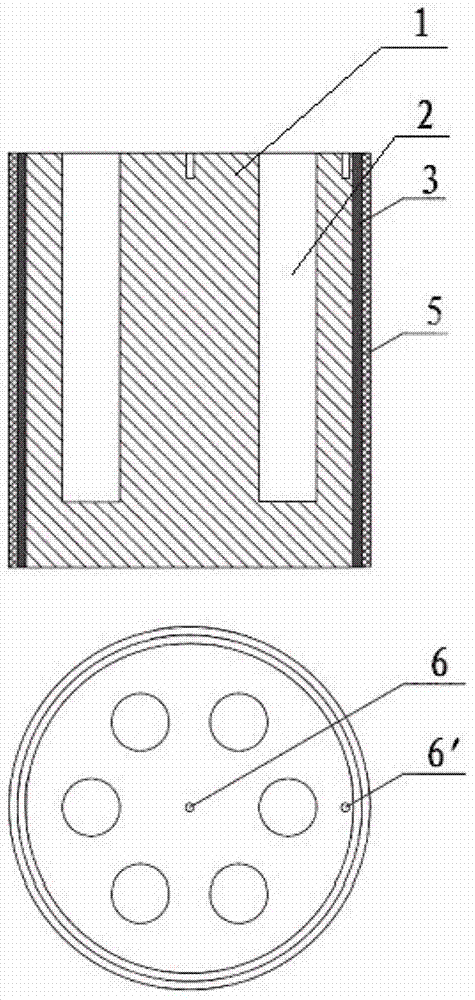

[0032] Rubber thermo-oxidative aging kinetics test device, including test bench 1, vacuum oxygen supply system 7, temperature control system 8, oxygen supply system 9, automatic recording system 10, wherein the test bench 1 is an integrated structure, the inside of the test bench The test chamber 2 is symmetrically arranged, the center and edge of the test bench 1 are respectively provided with a central temperature measuring sensor 6 and an edge temperature measuring sensor 6', and the periphery of the test bench 1 is provided with a heating belt 3 and an insulation layer 5 in sequence; the sealing end of the test chamber 2 is set The pressure sensor, the test chamber 2 are respectively connected with the evacuated oxygen supply system 7 and the oxygen supply system 9 , the heating belt 3 is connected with the temperature control system 8 , and the oxygen supply system 9 is connected with the automatic recording system 10 . Six test cavities are arranged symmetrically on the t...

Embodiment 2

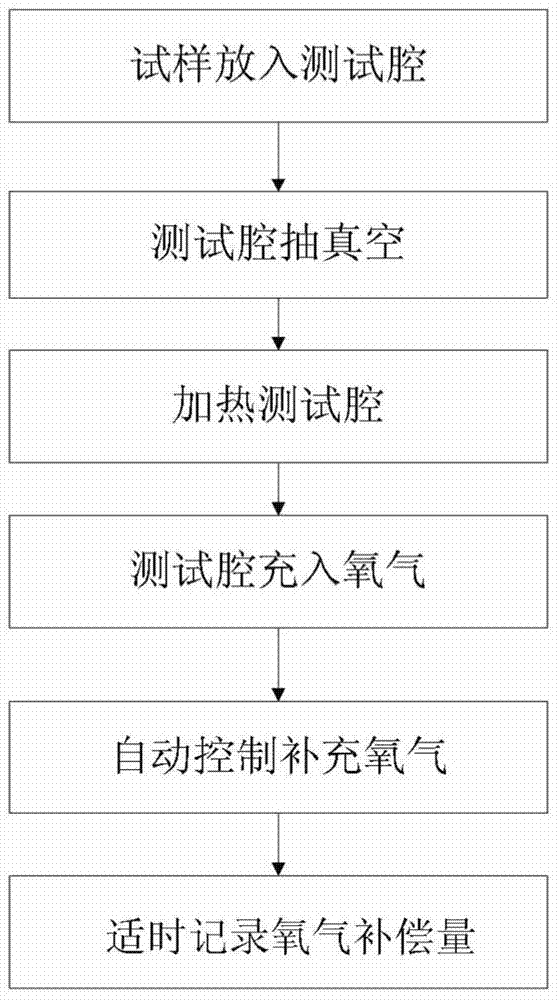

[0034] Start the temperature control system, heat the test chamber, and stop heating when it reaches 150°C; put the samples to be tested into the test chamber after numbering, and close the test chamber; start the vacuum pumping and oxygen supply system, and first vacuum the test chambers respectively , when the pressure in the test chamber is lower than 10pa, stop vacuuming, open the gas control valve and fill the test chamber with 1 bar of oxygen; the oxygen supply system will automatically supplement oxygen to the test chamber according to the pressure value of the pressure sensor; the automatic recording system will record in time Supplement the amount of oxygen, and output the thermal oxidation curve after the test.

Embodiment 3

[0036] Start the temperature control system, heat the test chamber, and stop heating when it reaches 200°C; put the samples to be tested into the test chamber after numbering, and close the test chamber; start the vacuum pumping and oxygen supply system, and first vacuum the test chambers respectively , when the pressure in the test chamber is lower than 10pa, stop vacuuming, and then open the gas control valve to fill the test chamber with 1bar oxygen; the oxygen supply system will automatically supplement oxygen to the test chamber according to the pressure value of the pressure sensor; the automatic recording system will timely Record the amount of supplemental oxygen, and output the thermal oxidation curve after the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com