Method for detecting explosive peroxide TATP

A technology of explosives and peroxidation, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of TATP effective detection, heat, collision, friction sensitivity, and increase the difficulty of detection, etc., to achieve effective Detection and Sensitivity Improvement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

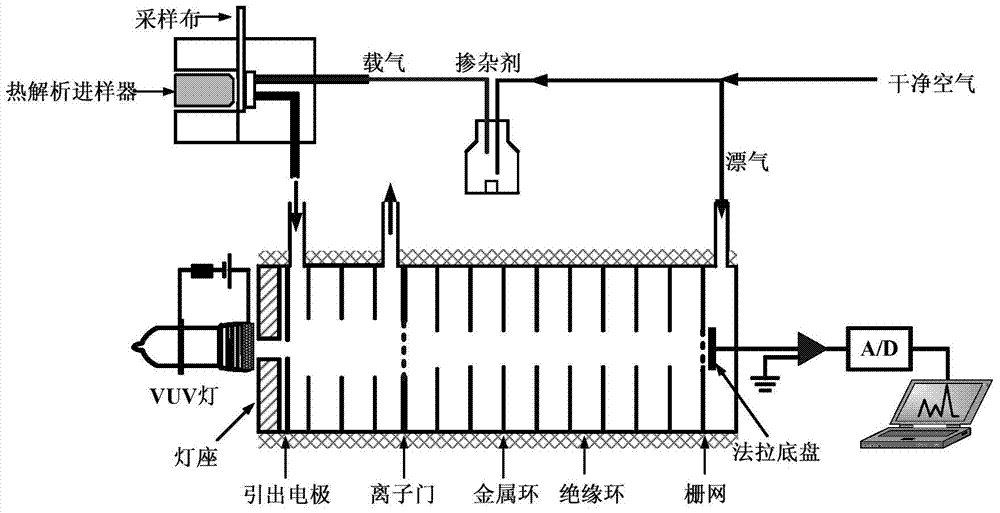

[0026] figure 1 It is a diagram of a dopant-assisted photoionization source ion mobility spectrometry device, which includes a photoionization source ion transfer tube, a dopant bottle, a thermal desorption sampler, a data acquisition system, a gas system, a heating system, etc.

Embodiment 2

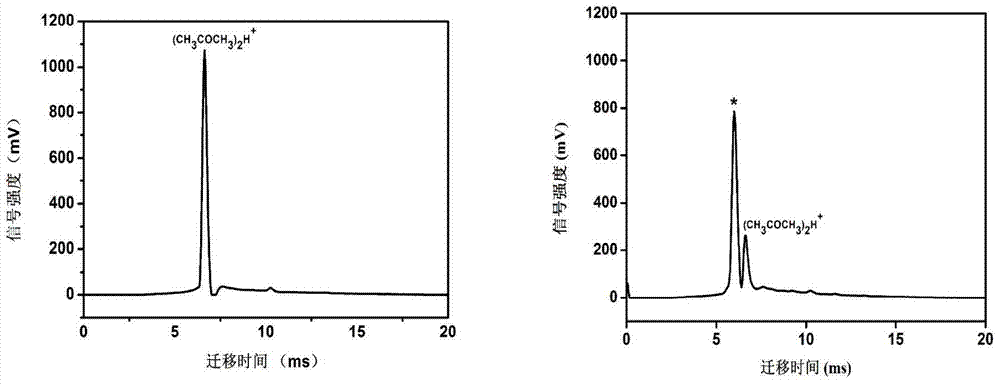

[0028] figure 2 In the positive ion mode, 25ppm acetone dopant is placed in the carrier gas, and the ion mobility spectra of no sample and 200ngTATP are compared. During the experiment, the transfer tube temperature was 120°C, the injector temperature was 60°C, the carrier gas (air) and drift gas (air) flow rates were 200mL / min and 500mL / min, respectively, and the humidity was controlled below 0.1ppm. The detection results show that for the detection of TATP, the dopant is placed in the carrier gas, and the ion mobility spectrometry as a dopant-assisted photoionization source has a good detection effect. Because the use of radioactive ionization sources can be avoided, and stable reagent ions can be generated under the conditions of photoionization sources, the detection sensitivity is improved, which is at least 100 times higher than the existing literature reports.

Embodiment 3

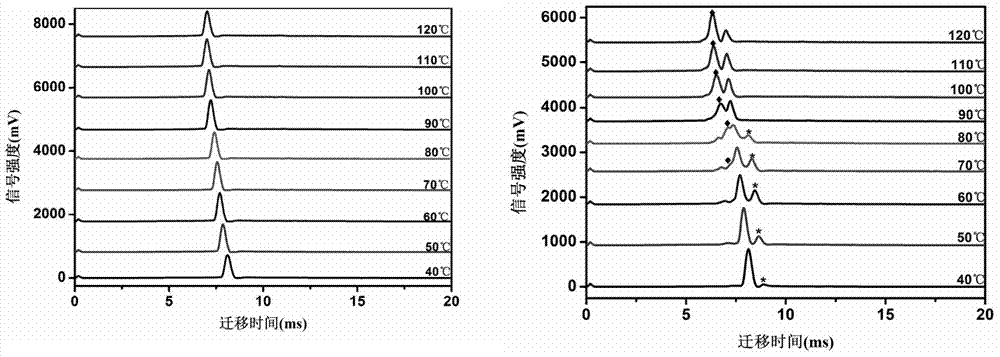

[0030] image 3 Ion mobility spectrograms showing the effect of different transfer tube temperatures on the detection of acetone reagent ions and TATP by dopant-assisted ionization source ion mobility spectrometry. Figure 4 are the signal intensity changes of product ion peaks at different transfer tube temperatures and the assignment of product ions. During the experiment, the temperature of the transfer tube was 40°C to 120°C, the temperature of the injector was 60°C, and the flow rates of carrier gas (air) and drift gas (air) were 200mL / min and 500mL / min, respectively. It can be seen from the figure that when the temperature of the transfer tube is controlled at 120°C, the optimal separation effect can be obtained. This is because when the transfer tube temperature is high, the TATP product ion peak is in front of the reagent ion peak, and the characteristic is relatively strong, and as the transfer tube temperature increases, the signal intensity is stronger

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com