Thermal transfer catalytic heat dissipation method

A heat dissipation method and heat transfer technology, used in heat transfer modification, heat exchange equipment, heat exchanger fixing, etc., can solve the problems of heat transfer bottlenecks and barriers, limited effectiveness, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

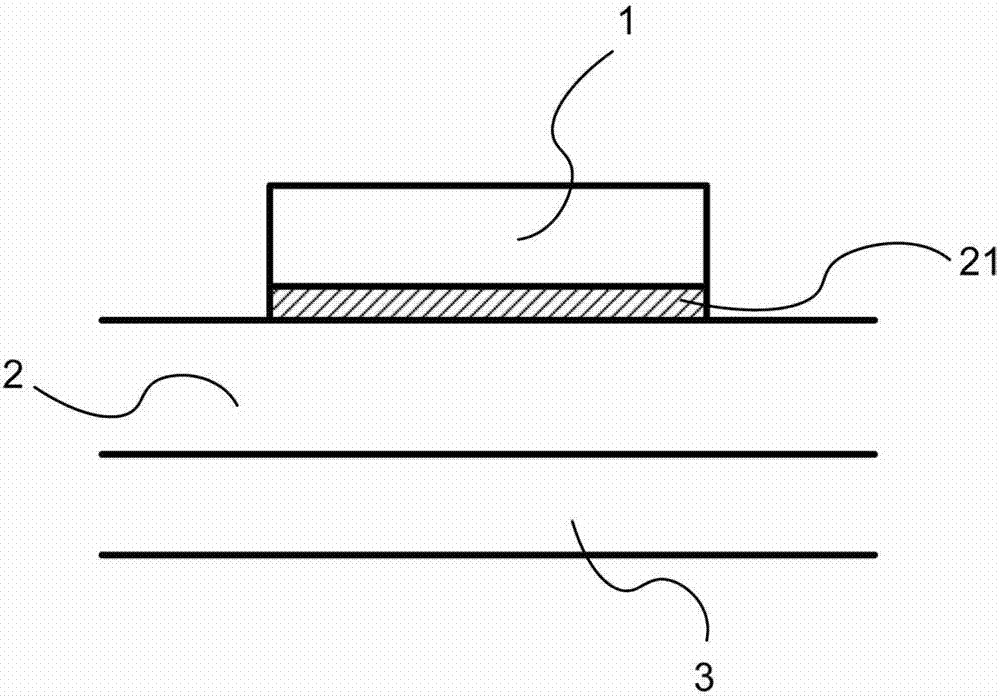

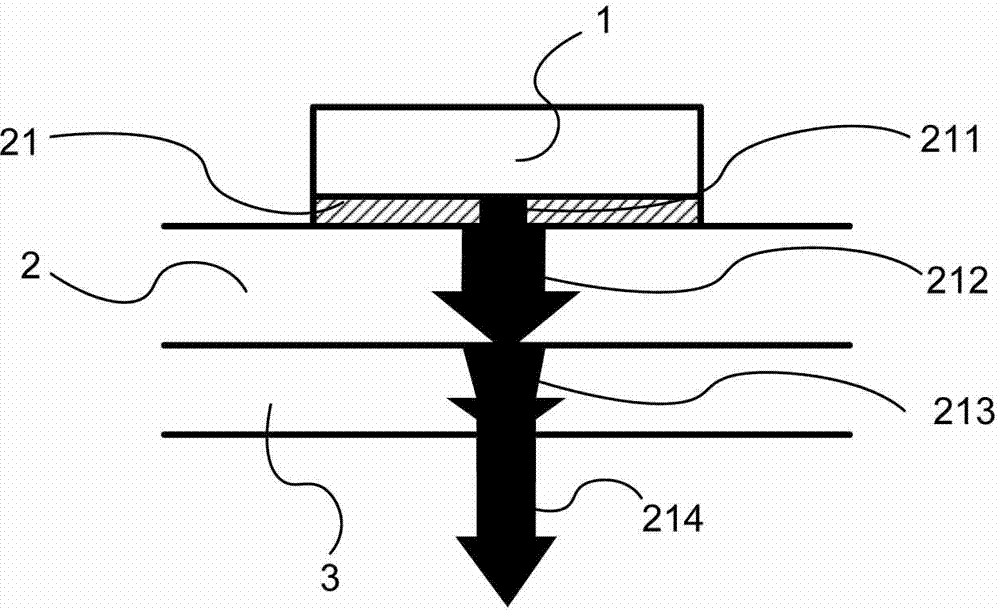

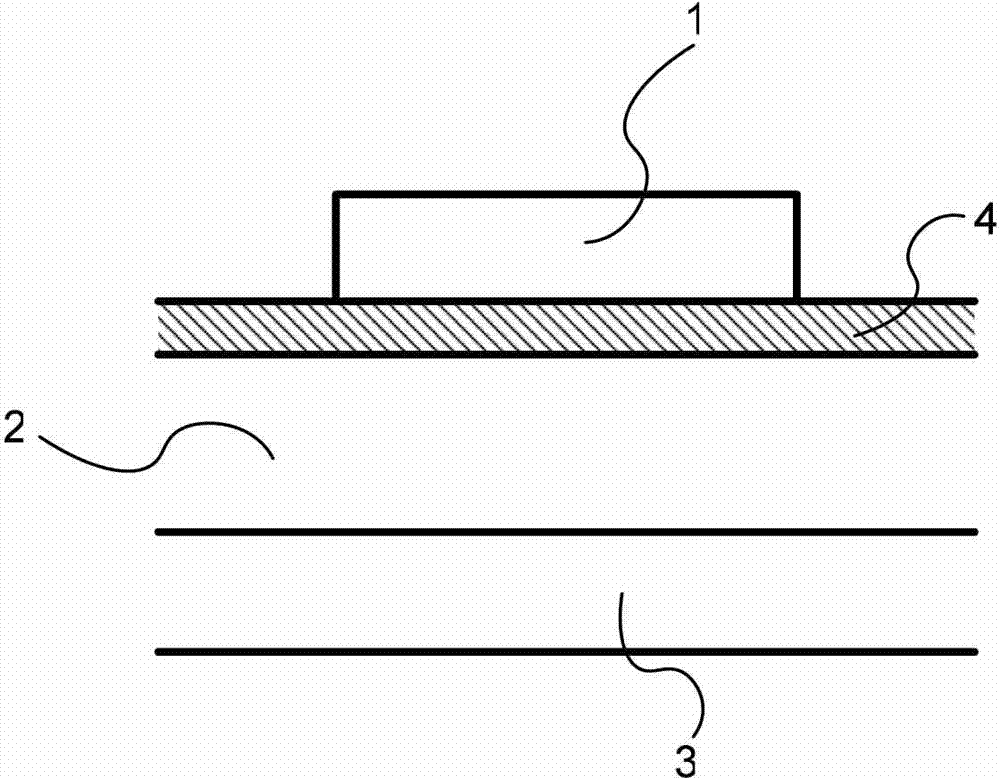

[0026] Please refer to FIG. 1 and FIG. 2 , which are respectively a schematic cross-sectional view of the first embodiment of the present invention and a schematic view of the heat transfer state of the first embodiment of the present invention. As shown in the figure: the present invention is a heat transfer catalytic heat dissipation method, which is provided with a heat transfer interface 2 on a heat source 1, and a six-membered ring carbon-based nano-carbon heat dissipation film 3 is provided on at least one side of the heat transfer interface 2 , so that after the heat transfer interface 2 absorbs the heat source, the six-membered ring carbon-based nano-carbon heat dissipation film 3 dissipates heat.

[0027] One surface of the heat transfer interface 2 is combined with the heat source 1, and the six-membered ring carbon-based nanocarbon heat dissipation film 3 is combined with the other surface of the heat transfer interface 2 (that is, the side of the heat transfer inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com