Coffee flower tea and making method thereof

A coffee flower and coffee technology, applied in the field of food deep processing, can solve the problems of high cost, no flower effect, large energy consumption, etc., and achieve the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

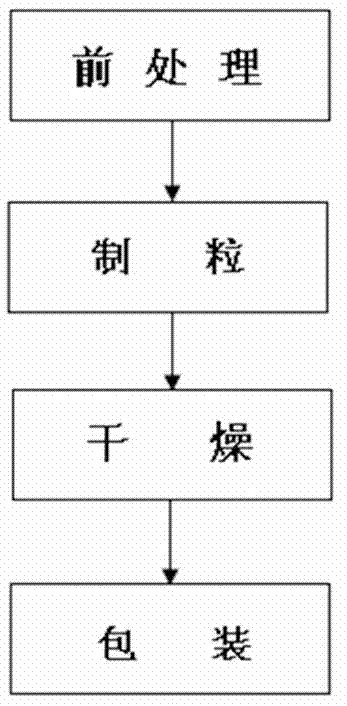

[0021] The preparation method of coffee scented tea of the present invention includes the steps of pretreatment, granulation, drying, and packaging inspection, which specifically includes:

[0022] A. Pre-treatment: Weigh the raw materials according to the proportion, crush them and sieve them for later use;

[0023] B. Granulation: granulate each raw material separately, mix evenly and granulate again to obtain the target;

[0024] C. Drying: drying the target;

[0025] D. Packaging inspection: Pack the dried target at 1~3 g / bag, and issue an inspection report when the packaging is completed.

[0026] The crushing and sieving described in step A is crushing through a 100-200 mesh sieve.

[0027] The moisture content of the raw materials before pulverization is controlled at 8-10%, and the drying method for raw materials with higher moisture content is to use baking, the baking temperature is 55°C to 65°C, and the baking time is 1 to 2 hours.

[0028] The drying described in step C uses...

Embodiment 1

[0032] Directly pulverize the coffee flower raw materials through a 200-mesh sieve, and pulverize the dried coffee flower through a 30-mesh sieve. First, pass the Pu-erh tea powder through the 18-mesh sieve granulated Pu-erh tea particles, then mix the Pu-erh tea particles and the coffee pollen evenly to granulate again The target product is obtained, dried for 3 hours at a baking temperature of 55°C to a moisture content of 10%, and the flower pregnant tea is packaged at 1g / bag, and a qualified inspection report is issued after the inspection is qualified.

Embodiment 2

[0034] Weigh 50 Kg of raw coffee flower and 50 Kg of green tea. The raw green tea is ultra-finely pulverized and passed through a 200-mesh sieve, and dried coffee flower is pulverized through a 30-mesh sieve. First, the green tea powder is passed through 18-mesh sieve granulated Pu-erh tea particles. Mix it with coffee pollen evenly and granulate again to obtain the target, and dry it at a baking temperature of 55°C for 3 hours to a moisture content of 10%. Pack the flower pregnant tea at 1g / bag, and issue a qualified inspection report after passing the inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com