Cold-resistant aqueous film forming foam extinguishing agent

A foam fire extinguishing agent and water film-forming technology, which is used in the field of foam fire extinguishing agent and water film-forming foam fire extinguishing agent, can solve the problems of inability to meet the storage and use requirements in extremely cold areas, and achieve small changes in main performance, long product shelf life, Good degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

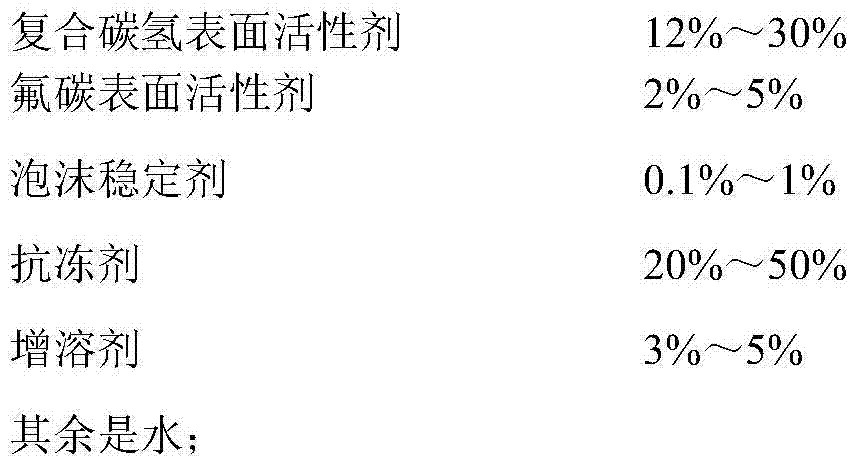

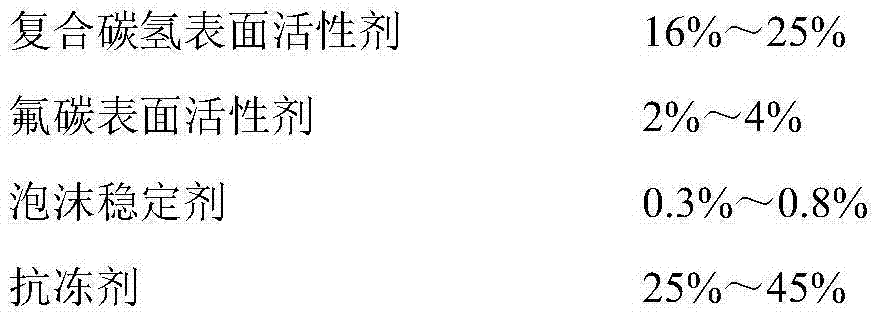

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (6%AFFF product)

[0035] During production of the cold-resistant aqueous film-forming foam fire extinguishing agent of this embodiment, under normal temperature and pressure, first weigh 0.3 kg of sodium alginate and 53.7 kg of water and add them to the kettle to fully stir and pre-dissolve, and then weigh cocamide Propyl betaine 10kg, alkyl polyglycoside (APG0810 produced by Yangzhou Chenhua New Material Co., Ltd.) 5kg, fluorinated alkyl betaine 2kg, ethylene glycol 25kg, urea 4kg, add in the reactor and fully stir and mix, Obtain the cold-resistant type aqueous film-forming foam fire extinguishing agent product of about 100kg.

Embodiment 2

[0037] During the production of the cold-resistant aqueous film-forming foam fire extinguishing agent of this embodiment, under normal temperature and pressure, first weigh 0.5 kg of sodium alginate and 35.9 kg of water and add them to the kettle to fully stir and pre-dissolve, and then weigh cocamide Propyl betaine 14kg, alkyl polyglucoside (APG0810 produced by Yangzhou Chenhua New Material Co., Ltd.) 7kg, fluorinated alkyl betaine 3kg, ethylene glycol 35kg, urea 4.6kg, add in the reaction kettle and fully stir and mix , to obtain about 100kg of cold-resistant type aqueous film-forming foam fire extinguishing agent product.

Embodiment 3

[0038] Embodiment 3 (3%AFFF product)

[0039] During production of the cold-resistant aqueous film-forming foam fire extinguishing agent of the present embodiment, under normal temperature and pressure, first weigh 0.8 kg of xanthan gum and 21.2 kg of water and add them to the kettle to fully stir and pre-dissolve, and then weigh cocamide propane Alkyl betaine 16kg, alkyl polyglycoside (APG0810 produced by Yangzhou Chenhua New Material Co., Ltd.) 8kg, fluorinated alkyl betaine 4kg, ethylene glycol 45kg, urea 5kg, add in the reactor and fully stir and mix to obtain About 100kg of cold-resistant aqueous film-forming foam fire extinguishing agent products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com