Covalent triazine skeleton doped hybrid membrane preparation method

A technology of covalent triazine skeleton and hybrid membrane, which is applied in the field of membrane separation, can solve the problem of low alcohol content, and achieve the effects of high repeatability, wide application, simple and efficient preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 covalent triazine framework material

[0031] Add 0.4 g of terephthalonitrile into the microwave reaction kettle, then add 2 milliliters of trifluoromethanesulfonic acid, quickly close the reaction kettle, put it into the microwave reactor and heat the reaction. The process adopts a temperature program, and the temperature is raised to 100 ° C in 3 minutes, and the temperature is raised to 100 ° C in 1 minute. The temperature was raised to 130°C in 30 seconds, then kept at 130°C for 30 minutes, and the temperature was naturally lowered after the reaction was completed. The product was washed with deionized water, ethanol, acetone, and tetrahydrofuran, respectively, and dried under vacuum at 180°C overnight to remove traces of trifluoromethanesulfonic acid.

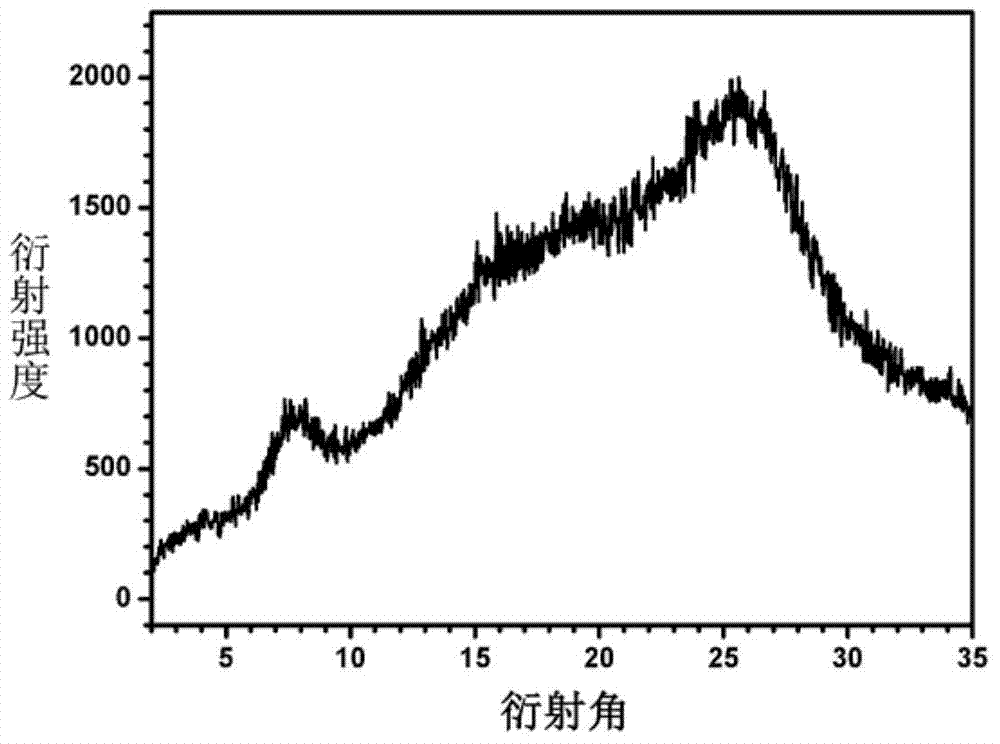

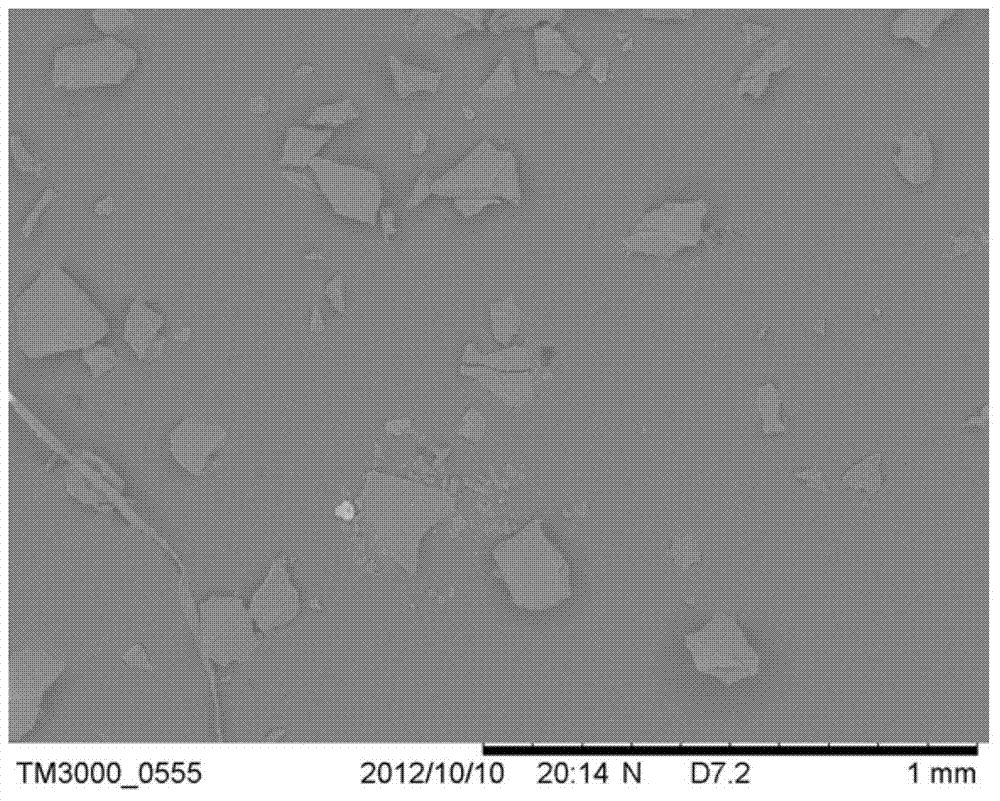

[0032] X-ray diffraction confirms that the product has a certain crystal form (such as figure 1 ), characteristic peak packets appear at 7°, 15° and 25°, respectively. Scanning elec...

Embodiment 2

[0033] The preparation of embodiment 2 covalent triazine framework material

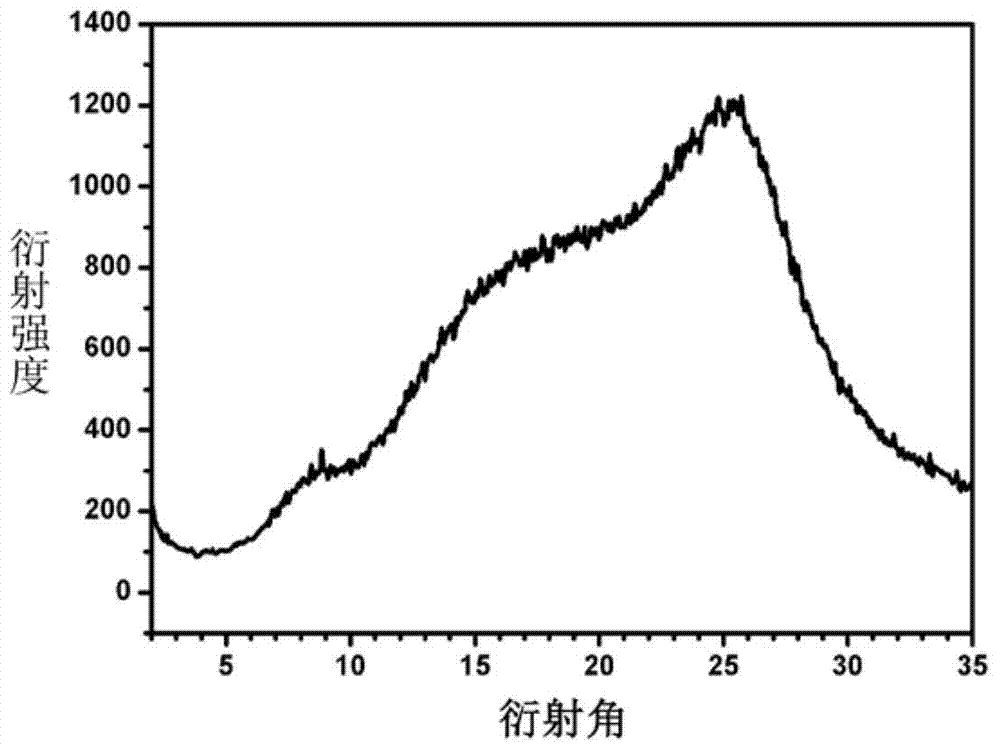

[0034] The same operation as in Example 1, but the addition of raw materials and the heating program are increased. 1g of terephthalonitrile powder is first added to the microwave reactor, and then 5 milliliters of trifluoromethanesulfonic acid catalyst is added. The heating program is 1 minute by room temperature. The temperature was raised to 90°C, then raised from 90°C to 110°C in 30 seconds, and then kept at 110°C for 30 minutes to allow the reaction to fully proceed, and finally the temperature was naturally lowered. X-ray diffraction confirms that the product also has a certain crystal form (such as image 3 ). This synthesis method can achieve one-time synthesis of a large number of CTF materials.

Embodiment 3

[0035] Example 3 Preparation of Covalent Triazine Framework Material Doped Silicone Rubber Hybrid Membrane

[0036] The CTF material is mixed into polymethylphenylsiloxane at a ratio of 10wt%, and the membrane solution is prepared as follows:

[0037] Solution (1): After mixing 0.2 g of CTF material and 3.3 g of isooctane, ultrasonically disperse the CTF material in a water bath for 5 minutes at room temperature;

[0038] Solution (2): Mix 0.02 g of organotin with 0.2 g of tetraethylorthosilicate, 2 g of polymethylphenylsiloxane, and 3.3 g of isooctane, and ultrasonicate in a water bath for 5 minutes.

[0039] Transfer the solution (2) into the solution (1), disperse the probe evenly by ultrasound at 0°C, immerse the prepared alumina tube or sheet in the membrane solution for 10 seconds, and then pull up to form a membrane. It is 60 mm / min; with the change of the viscosity of the film liquid, a film is pulled and prepared at regular intervals, and the film thickness becomes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com