A kind of olefin oligomerization catalyst and its preparation and use method

A catalyst and co-catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of low product yield, harsh reaction conditions, and raw material production efficiency Low-level problems, to achieve the effect of simple and efficient preparation and operation, simplification of steps and costs, and improvement of raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

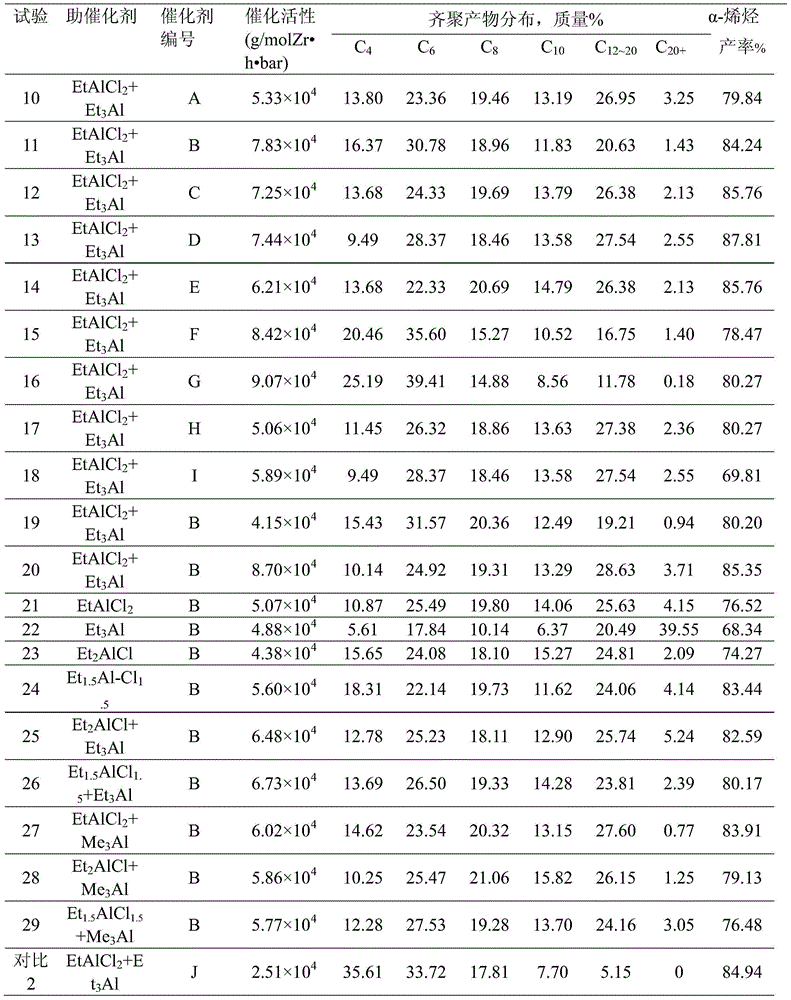

Examples

preparation example Construction

[0028] The steps of the preparation method of olefin oligomerization catalyst are as follows:

[0029] 1) 1-10 mmol of zirconium tetrachloride is placed in the reactor, 40-100 ml of reaction medium is added under the protection of nitrogen, the stirring is started, and the temperature is raised in a water bath, the reaction temperature is 50-90°C, preferably 60-80°C 0.5-2h, obtain the suspension of zirconium tetrachloride;

[0030] 2) Quickly add ArOH compounds with a syringe, the molar ratio of ArOH to zirconium tetrachloride is 1-12:1, heat up, the reaction temperature is 80-120°C, preferably 80-90°C, and at the same time cool to reflux and continue to stir , Keep for 2-6h to obtain olefin oligomerization catalyst, which can be used directly without separation.

[0031] The reaction medium is one or both of aromatic hydrocarbons and halogenated aromatic hydrocarbons. Benzene or toluene is preferred.

[0032] The method of using the olefin oligomerization catalyst: under a...

Embodiment 1

[0041] The following examples prepare oligomerization catalyst systems described in the present invention.

[0042] Accurately weigh 5 mmol ZrCl in the glove box 4 Place in a preparation reactor, add 20ml of toluene as a reaction medium under the protection of nitrogen, start stirring, heat with a water bath to 70°C and keep for 1h to obtain a suspension of zirconium tetrachloride in toluene. Quickly add 10mmol of phenol with a syringe, that is, the Zr:phenol molar ratio is 1:2, heat up to 85°C while cooling to reflux and keep stirring for 4h. According to the elemental analysis results, it is determined that the structure of the generated aryloxy zirconium compound is Zr(OC 6 h 5 ) 2 Cl, cooled to room temperature to obtain Zr(OC 6 h 5 ) 2 Cl solution in toluene A.

Embodiment 2

[0044] Add reaction system with 20mmol phenol, i.e. Zr: the phenol molar ratio is 1:4, and all the other operations are identical with embodiment 1, obtain aryloxy zirconium phenoxide compound structure as Zr(OC 6 h 5 ) 3 Cl·C 6 h 5 OH, Zr(OC 6 h 5 ) 3 Cl·C 6 h 5 OH solution in toluene B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com