Polysilane and resin composition containing polysilane

一种树脂组合物、聚硅烷的技术,应用在涂层等方向,能够解决复杂、分子设计溶解性限制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

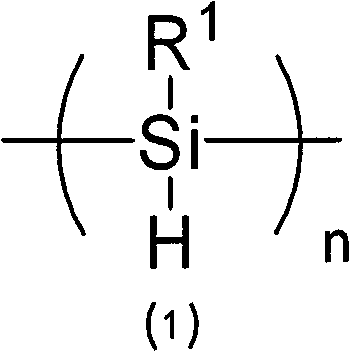

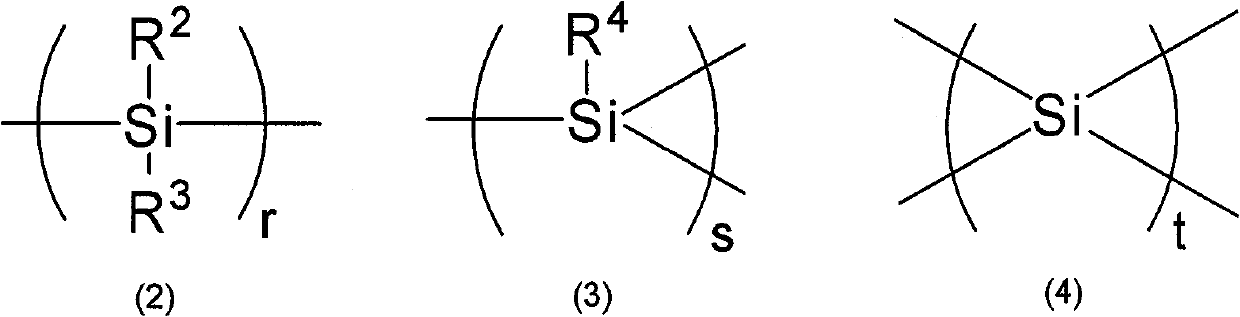

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0167](Example 1) Add 25g of magnesium particles (particle size: 20-1000m) and 20g of lithium chloride catalyst to a round bottom flask (internal volume: 1000ml) with a three-way cock, heat at 50°C and 1mmHg (=133Pa) under low pressure The contents of the reaction vessel (flask) were dried. Then, dry argon gas was introduced into the reaction vessel, 500 ml of tetrahydrofuran (THF) pre-dried using sodium-benzophenoneketyl was added thereto, and the mixture was stirred at 25° C. for about 60 minutes. 63.5 g (0.3 mol) of phenyltrichlorosilane purified by distillation and 34.5 g (0.3 mol) of methyldichlorosilane purified by distillation were added to the reaction mixture by syringe, and the resulting mixture was stirred at 25° C. for about 24 hours. After the reaction was completed, 1000 ml of 1N (=1 mol / L) hydrochloric acid was added to the reaction mixture, and the reaction mixture was extracted with 500 ml of toluene. Utilize 200ml aliquots of pure water to wash the toluene l...

Embodiment 2

[0169] (Example 2) 11.2 g of a copolysilane having a carboxyl group (yield: 100%) was obtained in a similar manner to Example 1 except that 5.0 g of ethyl acrylate in Example 1 was replaced with 3.7 g (50 mmol) of acrylic acid.

Embodiment 3

[0170] (Example 3) 11.2 g of a copolysilane having a carboxyl group (yield: 100%) was obtained in a similar manner to Example 2, except that 0.41 g of AIBN in Example 2 was replaced by 0.061 g of dibenzoyl peroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com