Lathe facilitating scrap iron collection

A technology for lathes and iron filings is applied in the field of lathes that are easy to collect iron filings, which can solve the problems of increasing the difficulty of handling, being easy to injure others, and not having obvious effects, and achieving the effects of simple structure, convenient operation, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

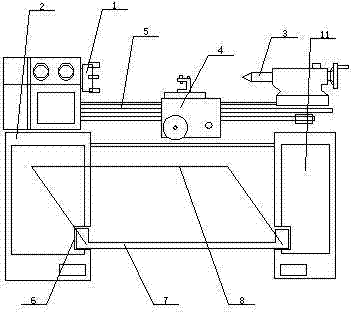

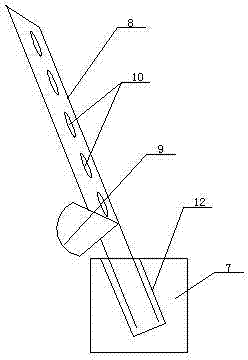

[0014] see figure 1 and figure 2 , the specific embodiment adopts the following technical solutions: it includes workpiece fixture 1, left frame 2, central rotating shaft 3, tool holder 4, screw mandrel 5, slot 6, drawer 7, baffle plate 8, angle adjustment device 9, magnet Block 10, right frame 11; workpiece fixture 1 is arranged on the left frame 2, is provided with several screw mandrels 5 between the left frame 2 and the right frame 11, is provided with adjustable tool rest 4 in the middle of the screw mandrel 5 , the right frame 11 is provided with a central rotating shaft 3, the symmetrical positions of the left frame 2 and the bottom of the right frame 11 are provided with a slot 6, the drawer 7 is movably arranged in the slot 6, and the outside of the drawer 7 is movably connected with a baffle plate 8. An angle adjustment device 9 is provided at the bottom of the baffle 8, and several magnet blocks 10 are arranged inside the baffle 8.

[0015] Preferably, the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com