Positioning system and positioning method for aeromotor installing vehicle

An aircraft engine and positioning system technology, applied in aircraft assembly, aircraft parts, and mechanical devices, etc., can solve the problems of inaccurate positioning, small action distance, difficult implementation, etc., to ensure efficiency and quality, accurate positioning methods, and improve The effect of the action distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

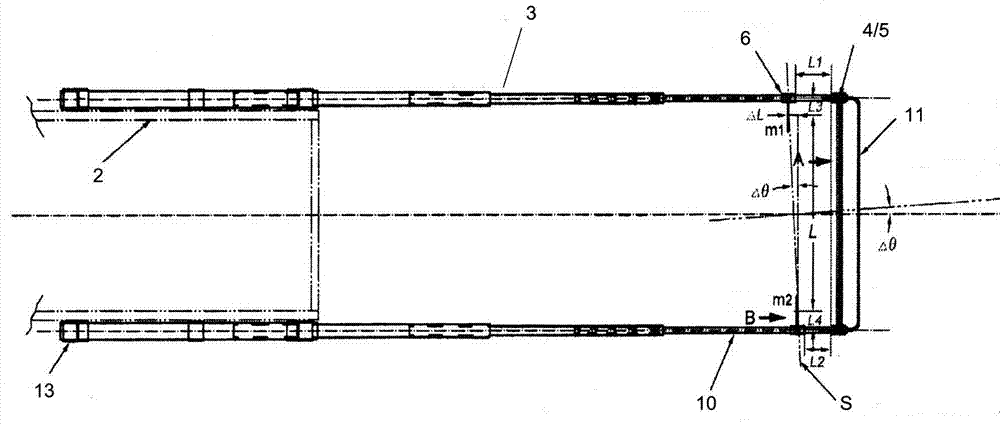

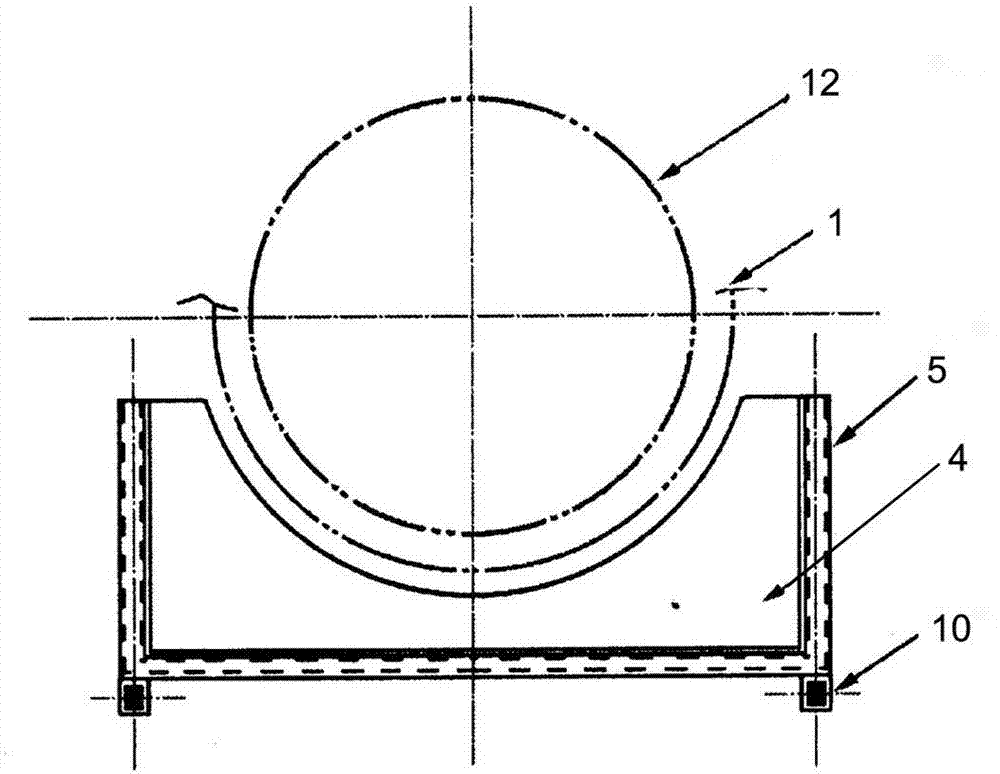

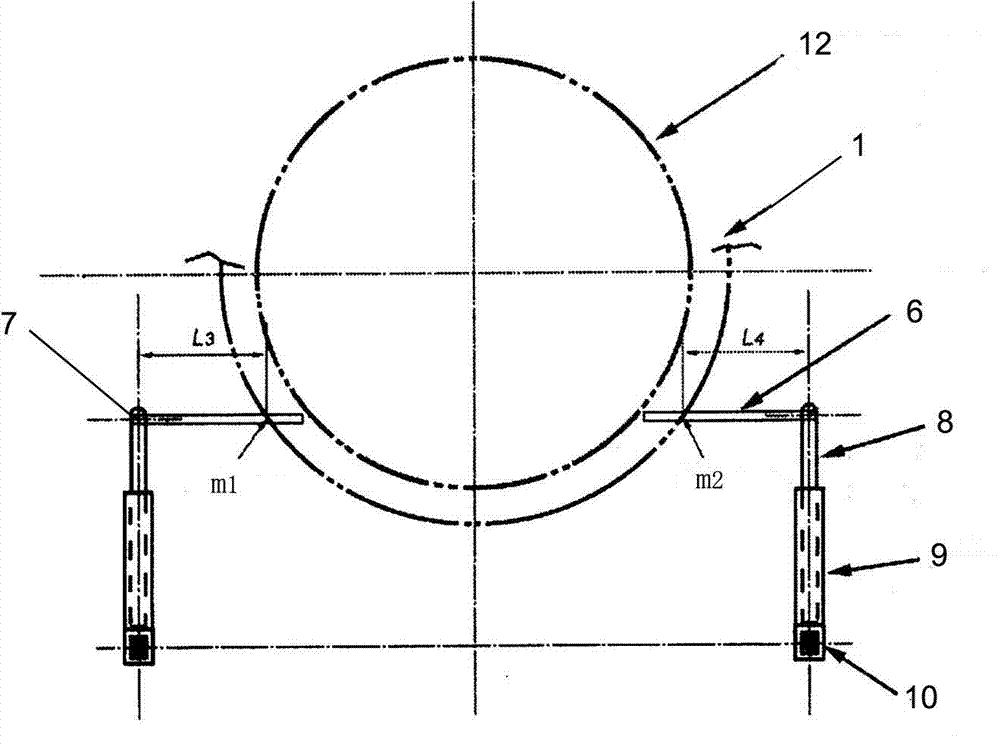

[0020] Such as figure 1 As shown, the aircraft engine is equipped with a vehicle positioning system, which includes two sets of multi-section telescopic arms 3, a clamp 4, a clamp base 5 and a pair of measuring arms 6, wherein the two sets of telescopic arms 3 are placed in parallel and They are respectively installed on the outside of the two longitudinal guide rails 2 at the front end of the installation vehicle. The telescopic support arm 3 adopts a multi-section telescopic structure, and the last support arm at the rear end is fixedly connected with the longitudinal guide rail 2 as a fixed section. The movable section can be stretched or shortened freely, and the first section of the support arm 10 at the front end is engraved with a scale line. The clamping plate 4 and the clamping plate base 5 are installed laterally on the end of the first section support arm 10 at the front end, and a beam handle 11 is connected to the front of the clamping plate base 5 .

[0021] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com