Ecological environment-friendly treatment method of dye or dye intermediate

A technology for dye intermediates and environmental protection treatment, which is applied in the direction of purification/separation of organic dyes, carboxylic acid nitriles, purification/separation of amino compounds, etc., and can solve problems such as the content does not meet the limit requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

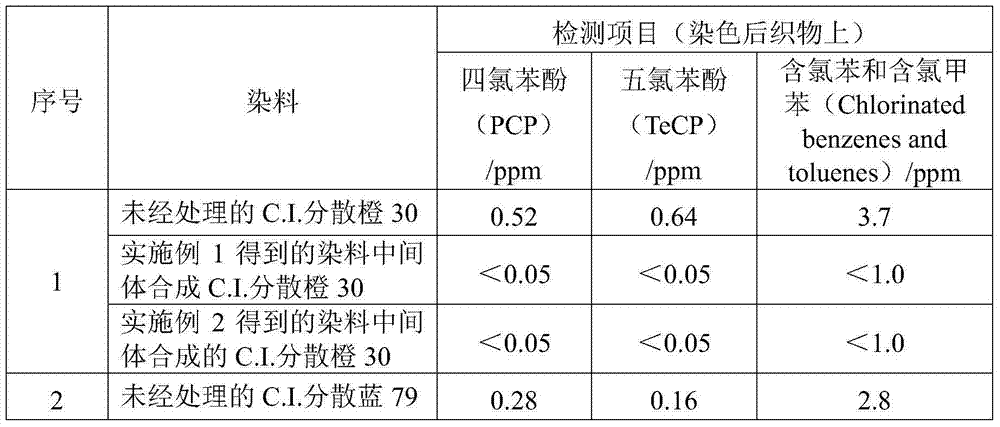

Examples

Embodiment 1

[0015] Add 135g of water to a 500ml three-necked flask, then add 40g of 2,6-dichloro-4-nitroaniline (p-nitroaniline synthesized by chlorination reaction) (100% amount, 0.19mol) and 30% hydroxide Sodium solution 25g (0.19mol), heated up to 60°C under normal pressure, and stirred and reacted at this temperature for 3 hours, after the reaction was completed, it was prepared by suction filtration and water washing.

Embodiment 2

[0017] Add 85g of water to a 500ml three-necked flask, then add 50g of 2,6-dichloro-4-nitroaniline (commercially available product), 75g of 20% ammonia water (0.43mol) and dichloro Ethane 100g (1mol), heat up to 75°C under normal pressure, and stir at this temperature for 4 hours. After the stirring time is up, distill and recover the organic solvent dichloroethane at 60-95°C under normal pressure. The recovered dichloroethane It can be applied mechanically next time, and then the reaction solution is suction-filtered and washed with water.

Embodiment 3~17

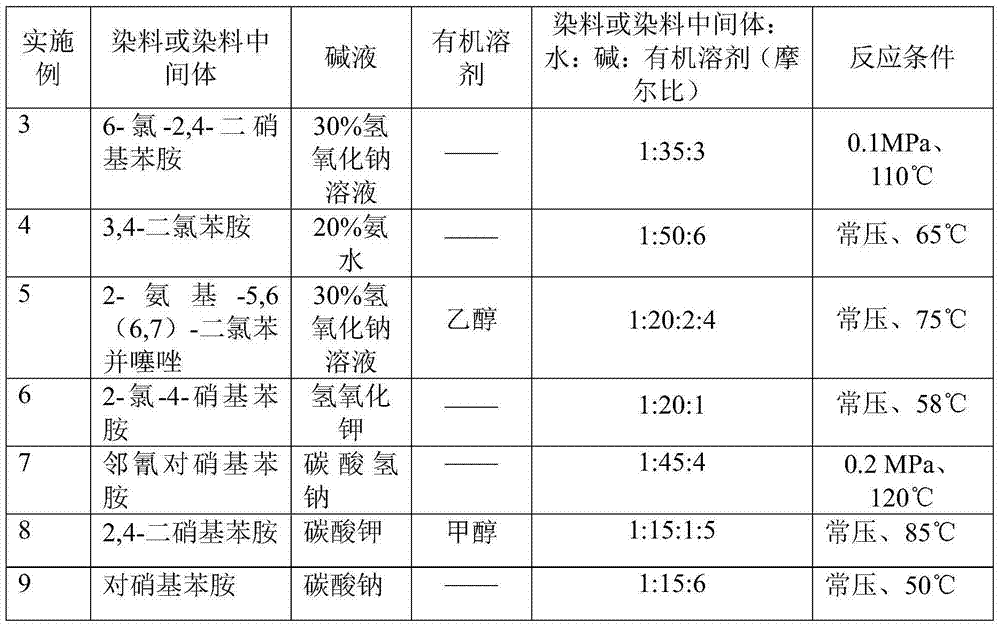

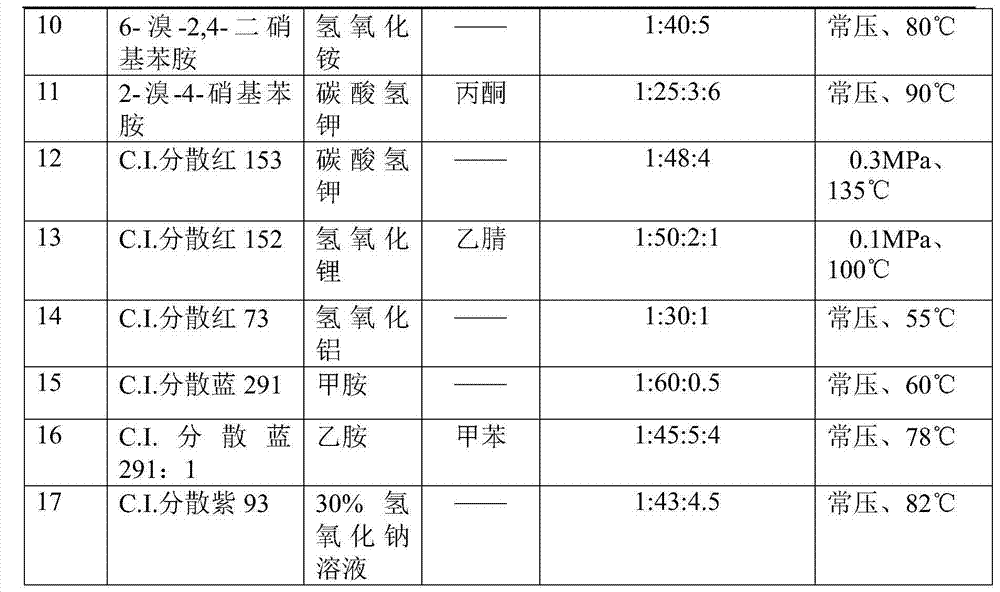

[0019] According to the method described in the above examples, after mixing the dye or dye intermediate, water, alkali agent and organic solvent according to the ratio in Table 1 (the amount of water in the table is the amount of water added separately), and then according to the respective reaction conditions Stir the reaction for 3-5 hours. If an organic solvent is added, the organic solvent is recovered by distillation under reduced pressure at 60-95°C after the reaction is completed, and finally the reaction solution is filtered and washed with water.

[0020] Table 1

[0021]

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com