Railway T-shaped beam integration super-high strength concrete-micro-porous ceramic compound sound barrier

A technology of ultra-high-strength concrete and microporous ceramics. It is applied in the field of sound-absorbing sound barriers and high-speed railway noise control. It can solve problems such as complex sound barrier structures, environmental pollution, and secondary noise, so as to avoid sound reflection and ensure stable quality. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential claims made by those skilled in the art based on the above-mentioned content of the present invention Improvements and adjustments also belong to the protection scope of the present invention.

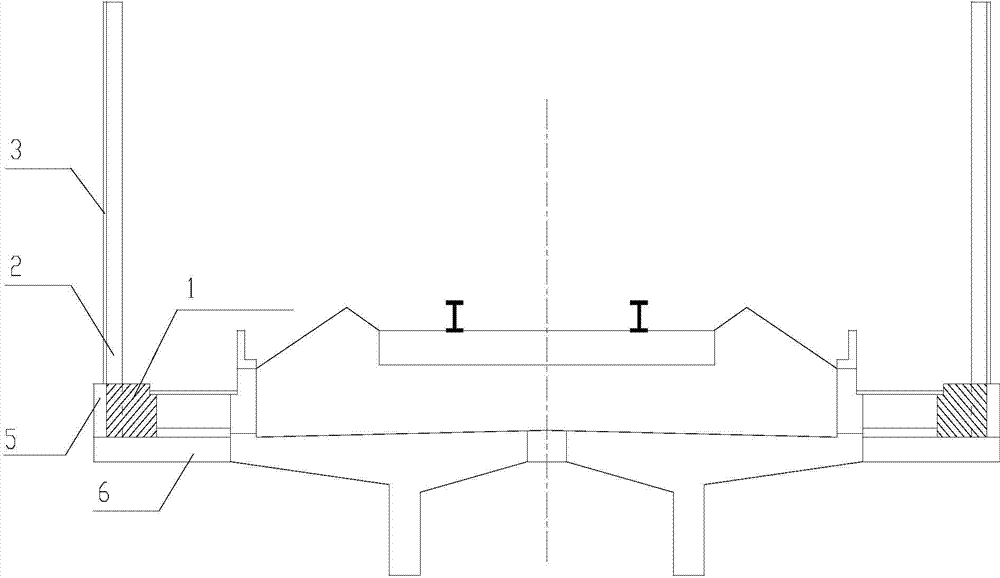

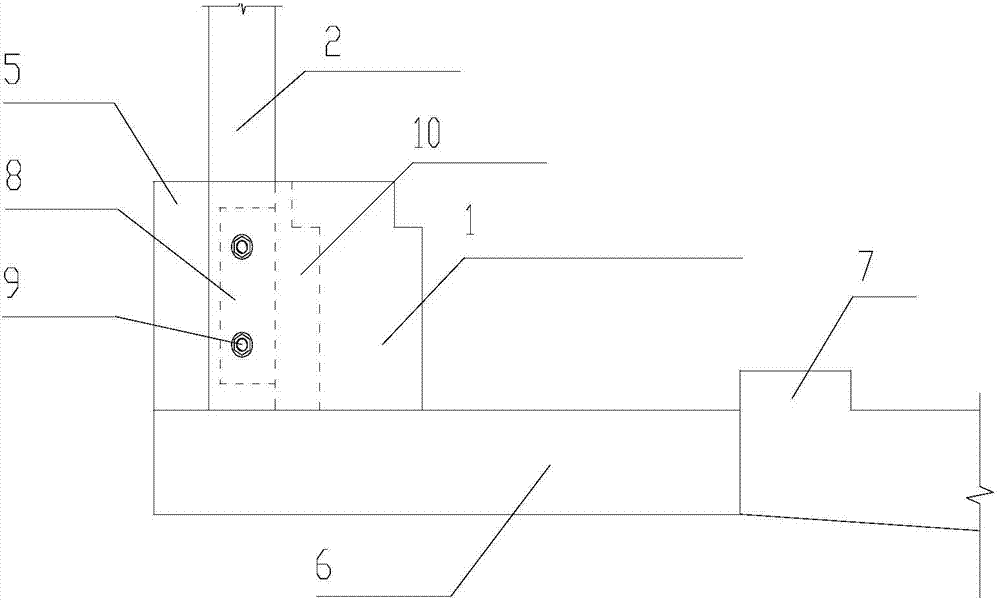

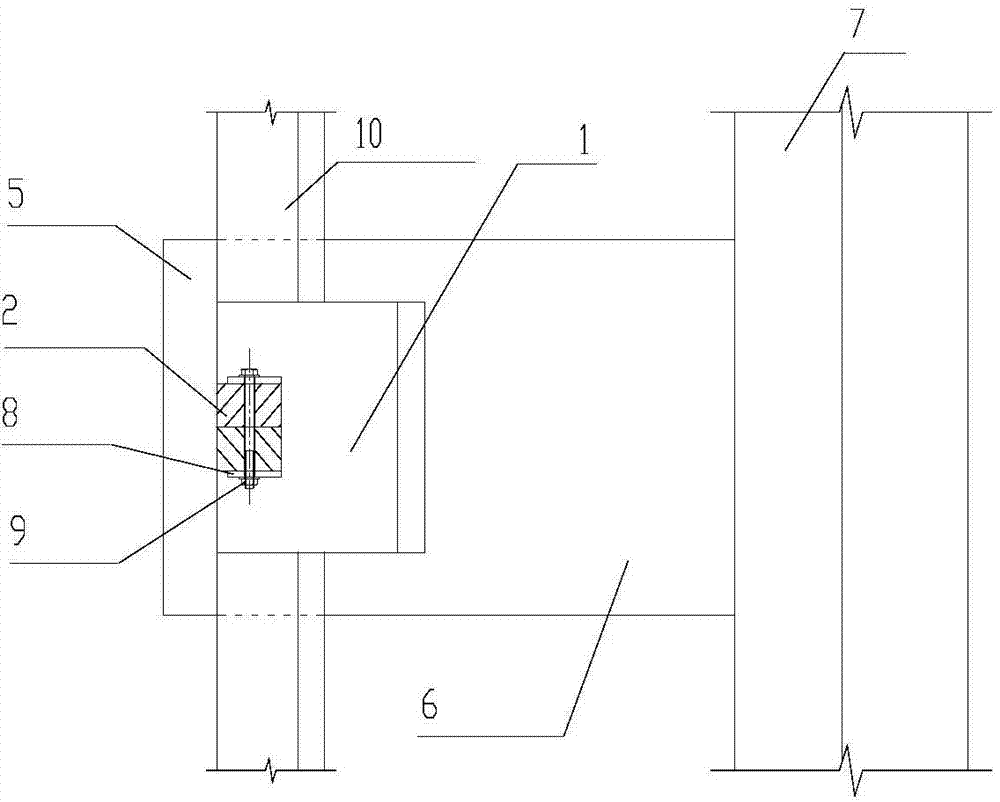

[0034] combine Figure 1 to Figure 8 .

[0035] Railway T-beam integrated ultra-high-strength concrete-microporous ceramic composite sound barrier, including railway foundation beams 6 for fixing the sound barrier, rib columns 2 arranged on the foundation beams 6 at intervals, and sound barriers fixed on the rib columns 2 The lower end of the rib column 2, the upper surface of the foundation beam 6, and the prefabricated retaining parts 5 outside the lower end of the rib column 2 are connected with each other by embedded reinforce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com