An electro-hydraulic control reversing valve with internal pressure relief function

An electro-hydraulic control reversing valve and reversing valve technology, which is applied to servo meter circuits, fluid pressure actuators, servo motor components, etc., can solve the problems of lack of multi-way reversing valve core, heavy structure, and use restrictions There are many problems, so as to ensure the safety of maintenance, simplify the oil circuit of the system, and facilitate the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

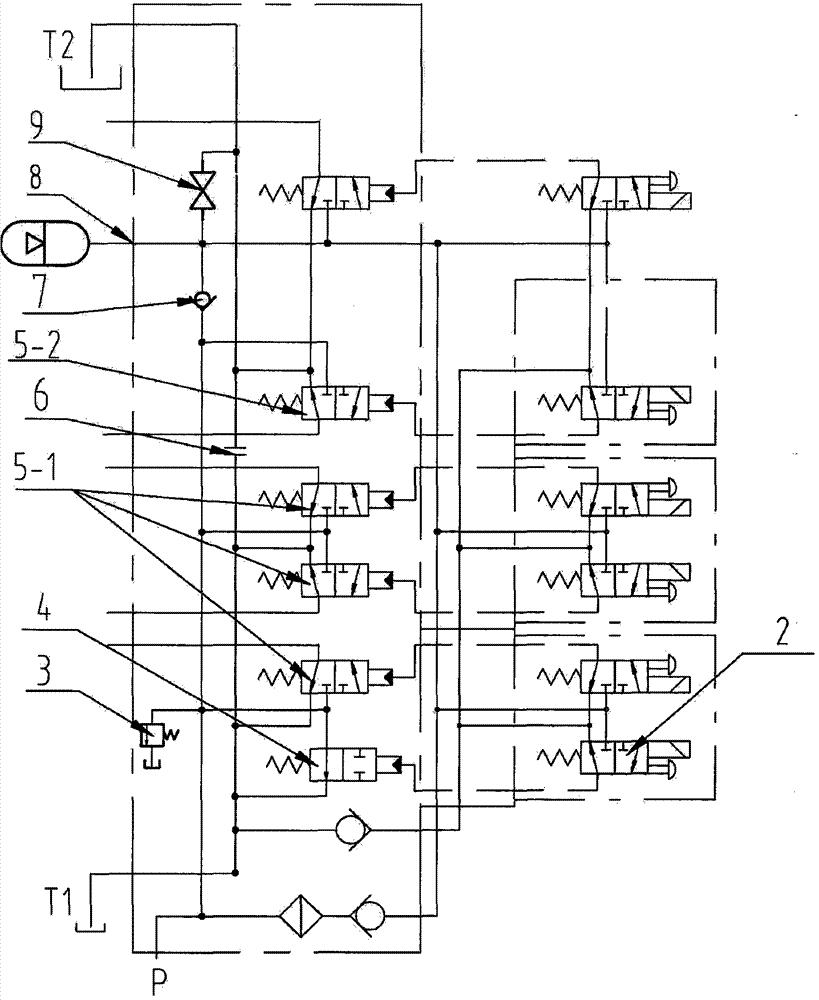

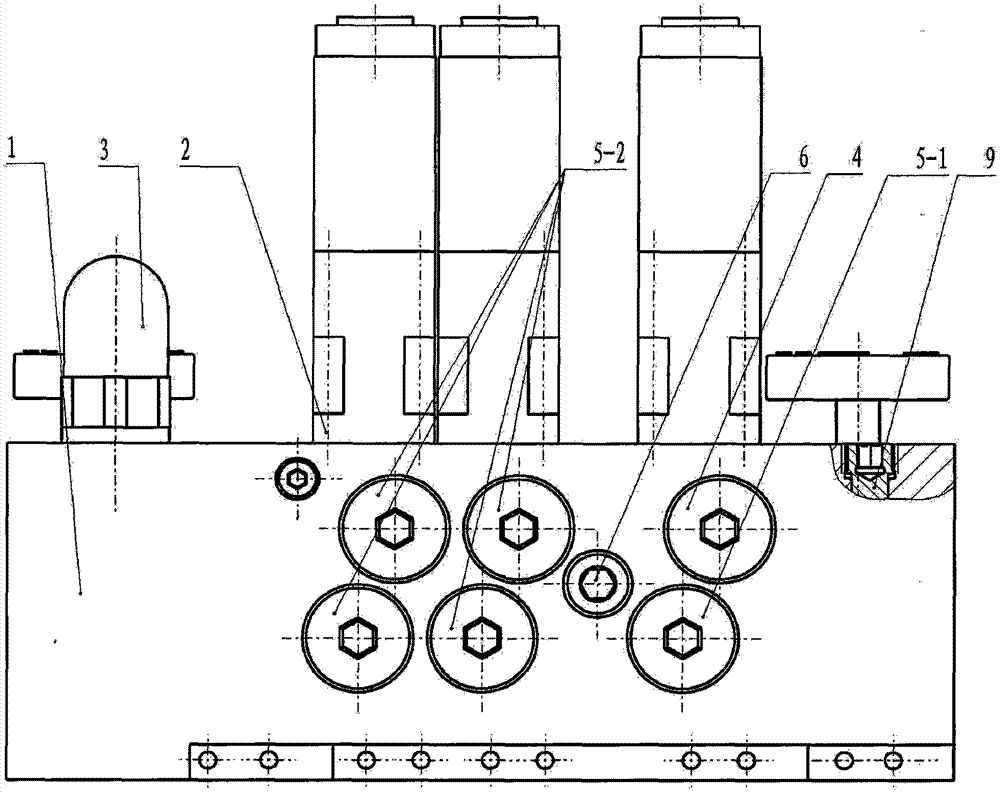

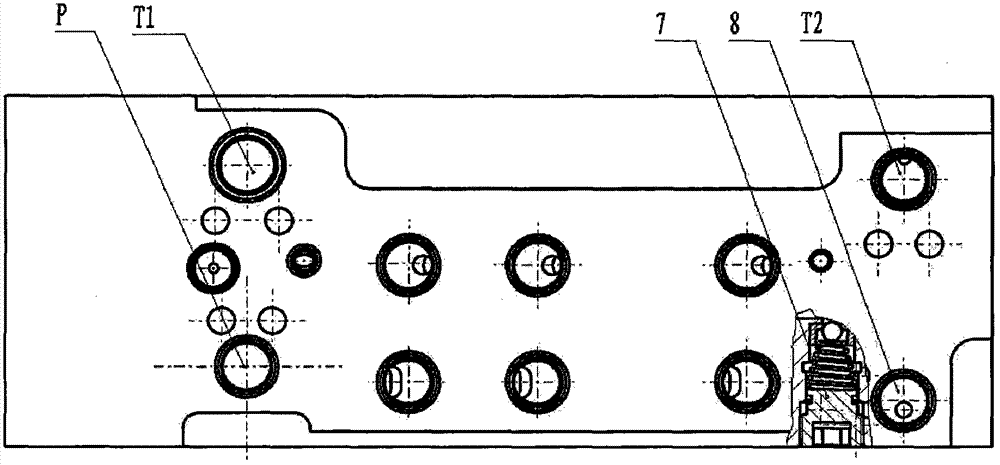

[0027] The schematic diagram of embodiment two, such as Figure 8 As shown, when the solenoid pilot valve is powered off, the unloading spool 4 disconnects the connection between the oil pump and the fuel tank; when the solenoid pilot valve is powered on, the oil pump is connected to the fuel tank; Figure 9 It is a specific implementation diagram of the integrated electro-hydraulic control reversing valve corresponding to the above schematic diagram. The difference is that there is an on-off valve in the unloading valve core. Oil pump and oil tank; when the electromagnetic pilot valve operates, the high-pressure control oil enters the back of the on-off valve, opens the on-off valve, connects the P port with the T2 port, and connects the oil pump and the oil tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com