Gas pipe pressure tapping opening connection method

A technology for gas pipelines and pressure openings, which is applied to pipes/pipe joints/fittings, pipes, branch pipelines, etc. It can solve problems that affect the continuity of enterprise production, have not been effectively solved, and have a greater impact on related processes. , to achieve the effect of reducing maintenance personnel, reducing labor intensity and reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The gas pipeline of the present invention adopts the following specific steps for the interface method of opening holes under pressure:

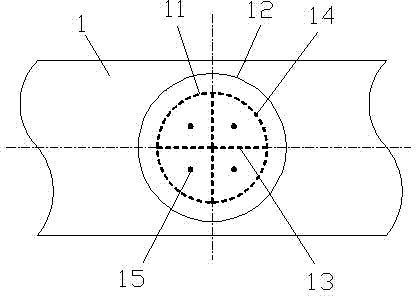

[0024] a. On the gas pipeline 1 that needs to be opened to take over, mark the circumferential position of the opening and the taking over. The opening circle 11 is located within the taking over circle 12. Divide the opening circle 11 into even 3-4 equal parts with the auxiliary line 13, Evenly get 15-20 measuring points on the hole circumference 11 and the auxiliary line 13 to measure the wall thickness of the gas pipeline 1 to prepare for the hole.

[0025] b. Drill and ream small holes 14 on the circumference of the hole 11 and the auxiliary line 13. The small holes 14 are evenly spaced along the circumference of the hole 11 and the auxiliary line 13. The depth of the small holes 14 is limited by the drill sleeve, which must be guaranteed The pipe wall of the gas pipeline 1 has at least 1-2mm thin wall.

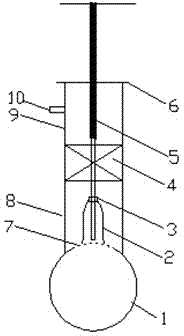

[0026] c. Weld the shac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com