High-optical-subdivision grating interferometer based on plane mirrors

A technology of grating interference and plane mirror, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problem of low optical subdivision multiples, and achieve the effect of high optical subdivision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

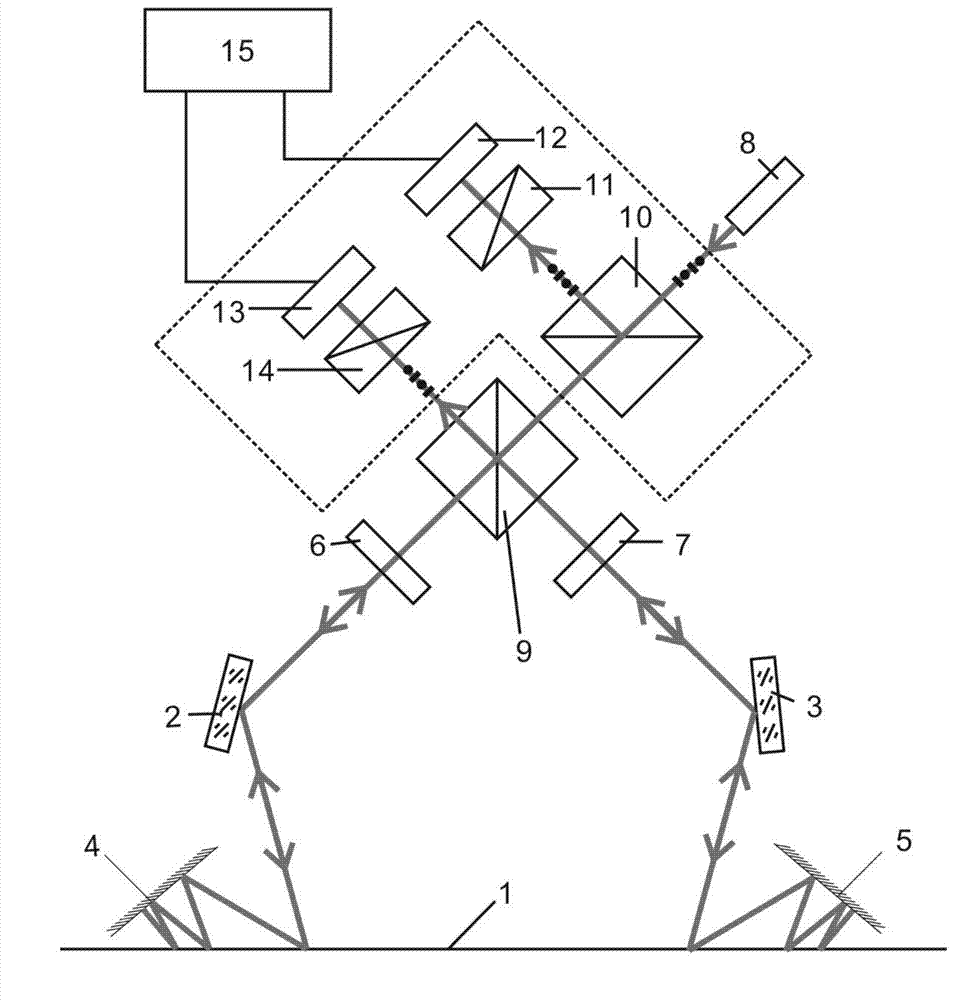

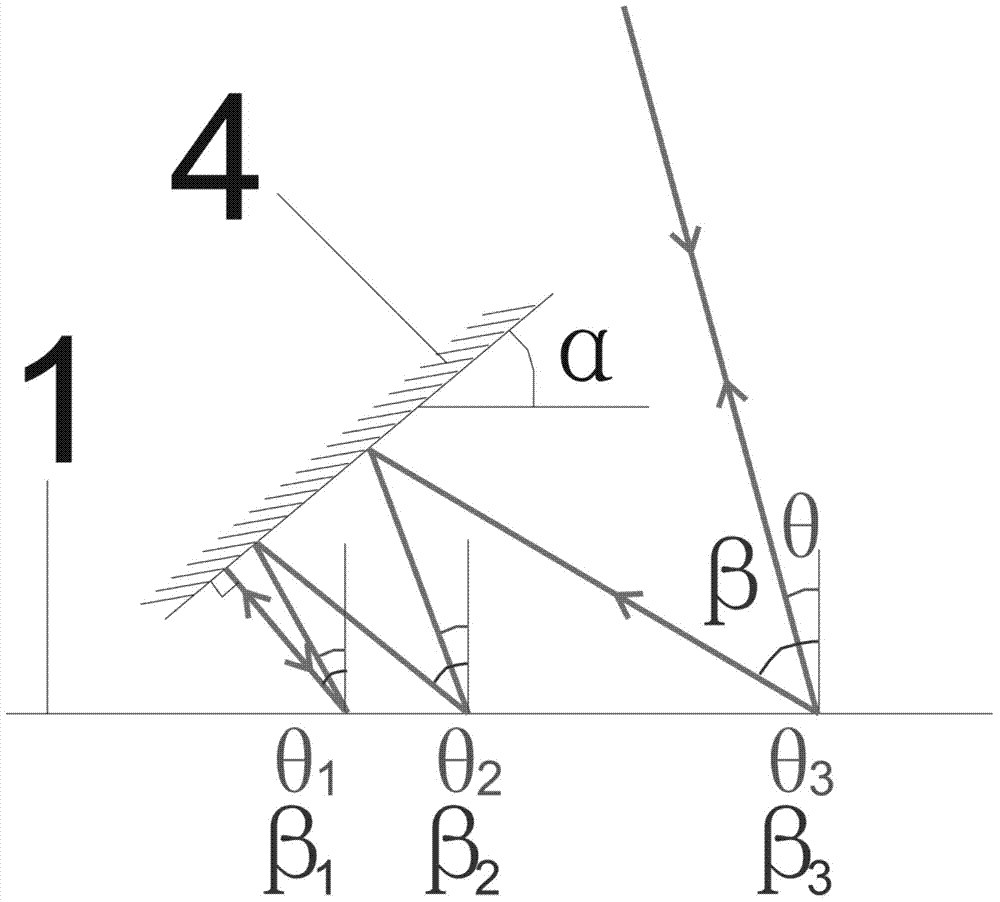

[0012] Such as figure 1 As shown, the dual-frequency orthogonal linearly polarized laser light source 8 emits an orthogonal dual-frequency polarized light beam which is divided into two beams by a non-polarizing beam splitter 10, and one beam is injected into the first analyzer 11 to form an interference signal, which is detected by the first detector 12 is received as a reference signal for dual-frequency heterodyne interferometry and transmitted to the data acquisition and processing and control unit 15, and the other beam is divided into transmitted P light and reflected S light by a polarization beam splitter 9. The P light coming out of the polarizing beam splitter 9 is transformed into right-handed circularly polarized light through the first quarter-wave plate 6, ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com