Pretreatment method of harmful substances in milk samples smelted and extracted in freezing area

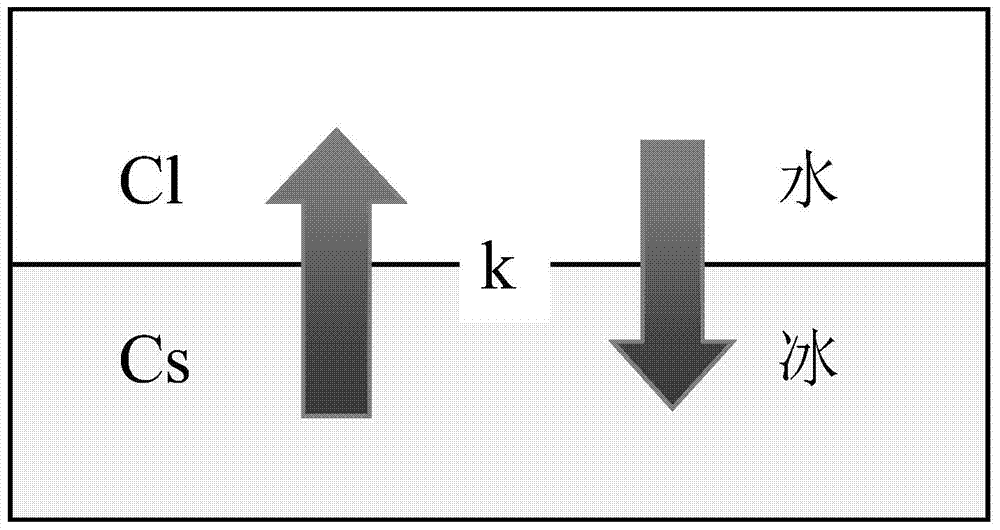

A technology for hazardous substances and regional smelting, which is used in the pretreatment of smelting and extracting hazardous substances in milk samples in freezing areas, and the pretreatment of hazardous substances in milk powder samples, which can solve problems such as increased analysis costs, high consumption, and secondary pollution. , to achieve the effect of eliminating interfering components, simple and convenient operation, and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

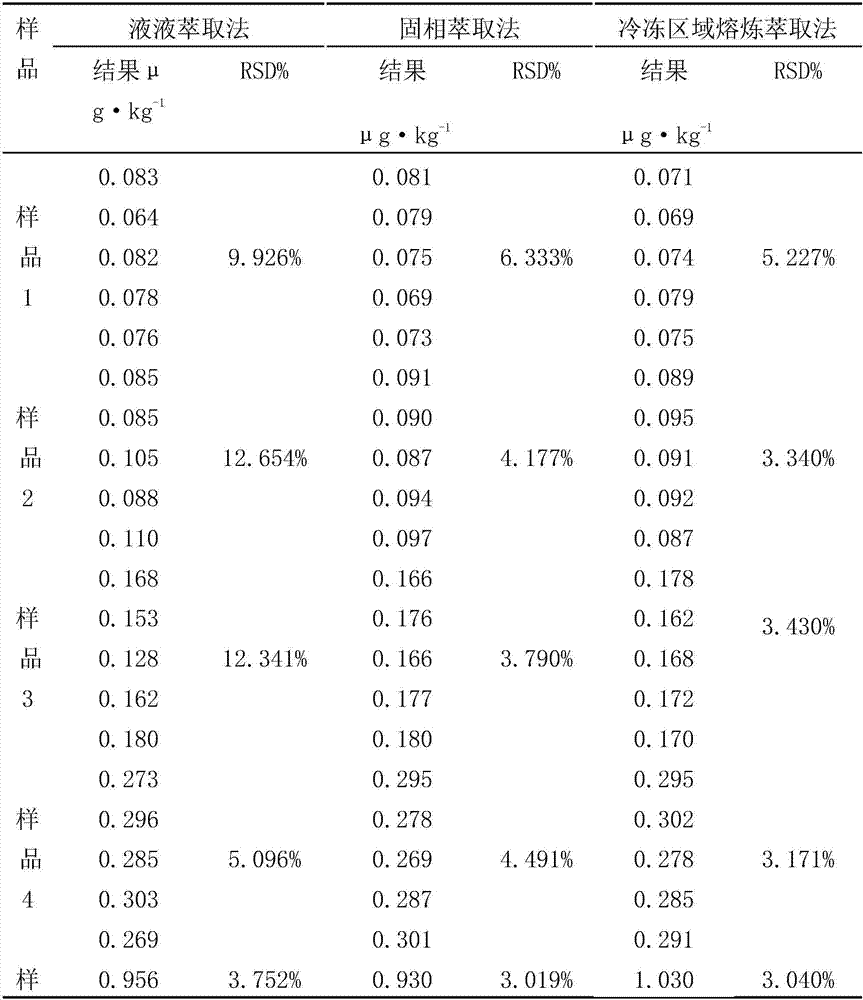

Examples

Embodiment 1-1

[0056] (1) Weigh 8g of solid milk powder sample, add 65mL of ultrapure water to the solid milk powder sample, mix with 35mL of saturated ethyl acetate, vortex extract for 3min, and shake at medium speed for 3min to obtain the treatment solution;

[0057] (2) Pour the treatment liquid obtained in step (1) into a high-pressure freezing extraction kettle, cover the lid tightly, and tighten the lid of the kettle body, then open the sealing bolt on the lid of the kettle, and use a syringe to pass through the small hole in the lid of the kettle Inject an appropriate amount of saturated ethyl acetate into the high-pressure freezing extraction kettle, and discharge the remaining air bubbles in the high-pressure freezing extraction kettle;

[0058] (3) Screw the sealing bolt on the lid of the kettle into the lid of the kettle, and tighten it, put the high-pressure freezing extraction kettle in a refrigerator at -20°C for 2 hours, or put it in an ice bath for 30 minutes;

[0059] (4) Take...

Embodiment 1-2

[0061] (1) Weigh 5 g of the solid milk powder sample, add 50 mL of ultrapure water to the solid milk powder sample, mix with 20 mL of saturated ethyl acetate, vortex extract for 1 min, and then shake at a medium speed for 2 min to obtain the treatment solution;

[0062] (2) Pour the treatment liquid obtained in step (1) into a high-pressure freezing extraction kettle, cover the lid tightly, and tighten the lid of the kettle body, then open the sealing bolt on the lid of the kettle, and use a syringe to pass through the small hole in the lid of the kettle Inject an appropriate amount of saturated ethyl acetate into the high-pressure freezing extraction kettle, and discharge the remaining air bubbles in the high-pressure freezing extraction kettle;

[0063] (3) Screw the sealing bolt on the lid of the kettle into the lid of the kettle, and tighten it, put the high-pressure frozen extraction kettle in a refrigerator at -18°C for 1.8 hours, or put it in an ice bath for 25 minutes; ...

Embodiment 1-3

[0066] (1) Weigh 10 g of solid milk powder sample, add 80 mL of ultrapure water to the solid milk powder sample, mix with 50 mL of saturated ethyl acetate, vortex extract for 5 minutes, and then oscillate at medium speed for 5 minutes to obtain the treatment solution;

[0067] (2) Pour the treatment liquid obtained in step (1) into a high-pressure freezing extraction kettle, cover the lid tightly, and tighten the lid of the kettle body, then open the sealing bolt on the lid of the kettle, and use a syringe to pass through the small hole in the lid of the kettle Inject an appropriate amount of saturated ethyl acetate into the high-pressure freezing extraction kettle, and discharge the remaining air bubbles in the high-pressure freezing extraction kettle;

[0068] (3) Screw the sealing bolt on the lid of the kettle into the lid of the kettle, and tighten it, put the high-pressure freezing extraction kettle in a refrigerator at -22°C for 2.2 hours, or put it in an ice bath for 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com