Preparation method of fig slices

A technology of figs and fruit slices, which is applied in the field of preparation of fig fruit slices, can solve the problem of no ready-to-eat food for figs, and achieve the effects of convenient carrying and eating, simple production process, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

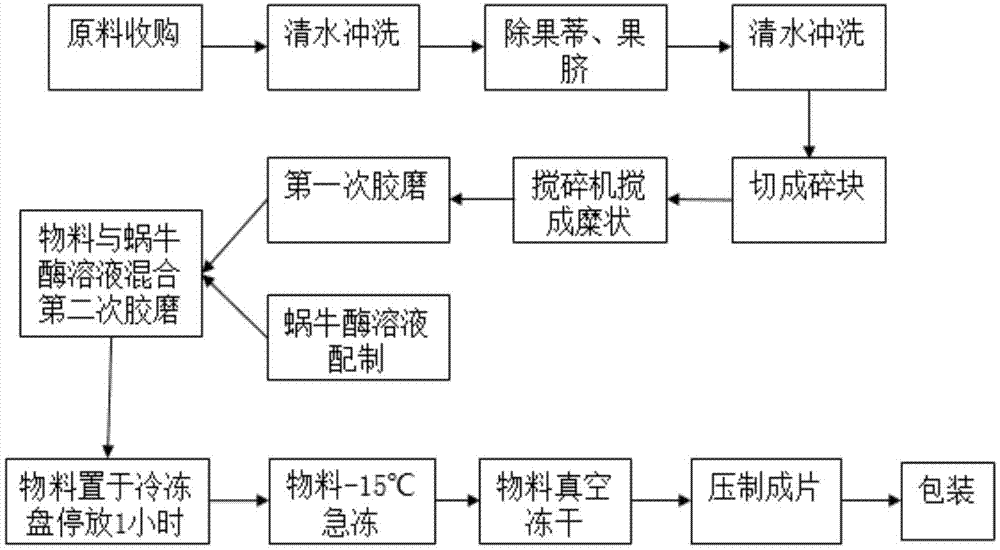

Image

Examples

Embodiment 1

[0040] (1) Raw material acquisition:

[0041] Choose figs that are pollution-free and free from diseases and insect pests, and the maturity of the figs is controlled at 9 mature.

[0042] (2) Primary treatment of raw materials:

[0043] Rinse the above-mentioned raw materials with clean water repeatedly, and remove the pedicle and navel of the fig.

[0044] (3) Raw material crushing:

[0045] Cut 100 kilograms of figs into 1cm-sized fragments through a shredder, and then stir them into mince with a shredder;

[0046] (4) Preparation of rubber mill and helicase solution for the first time:

[0047] Adopt rubber mill to carry out rubber milling for the first time to the minced fig; meanwhile, adopt 20 grams of helicase to add 3000 grams of water to dissolve into helicase solution, that is to say the weight of helicase is 2 / 10,000 of the total weight of fig.

[0048] (5) The material is mixed with the helicase solution for the second rubber mill:

[0049] Add 3 kg of adjuste...

Embodiment 2

[0058] (1) Raw material acquisition:

[0059] Choose figs that are pollution-free and free from diseases and insect pests, and the maturity of the figs is controlled at 9 mature.

[0060] (2) Primary treatment of raw materials:

[0061] Rinse the above-mentioned raw materials with clean water repeatedly, and remove the pedicle and navel of the fig.

[0062] (3) Raw material crushing:

[0063] Cut 200 kilograms of figs into 1cm-sized fragments through a shredder, and then stir them into mince with a shredder;

[0064] (4) Preparation of rubber mill and helicase solution for the first time:

[0065] Adopt rubber mill to carry out rubber milling for the first time to the minced fig; meanwhile, adopt 40 grams of helicase to add 6000 grams of water to dissolve into helicase solution, that is to say the weight of helicase is 2 / 10,000 of the total weight of fig.

[0066] (5) The material is mixed with the helicase solution for the second rubber mill:

[0067] Add 6 kg of adjuste...

Embodiment 3

[0076] (1) Raw material acquisition:

[0077] Choose figs that are pollution-free and free from diseases and insect pests, and the maturity of the figs is controlled at 9 mature.

[0078] (2) Primary treatment of raw materials:

[0079] Rinse the above-mentioned raw materials with clean water repeatedly, and remove the pedicle and navel of the fig.

[0080] (3) Raw material crushing:

[0081] Cut 300 kilograms of figs into 1cm-sized fragments through a shredder, and then stir them into mince with a shredder;

[0082] (4) Preparation of rubber mill and helicase solution for the first time:

[0083] Adopt rubber mill to carry out rubber milling for the first time to the minced fig; meanwhile, adopt 60 grams of helicase to add 9000 grams of water to dissolve into helicase solution, that is to say the weight of helicase is 2 / 10,000 of the total weight of fig.

[0084] (5) The material is mixed with the helicase solution for the second rubber mill:

[0085] Add 9 kg of adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com