Spring coil and production method thereof

A spring coil, winding technology, applied in the field of medical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

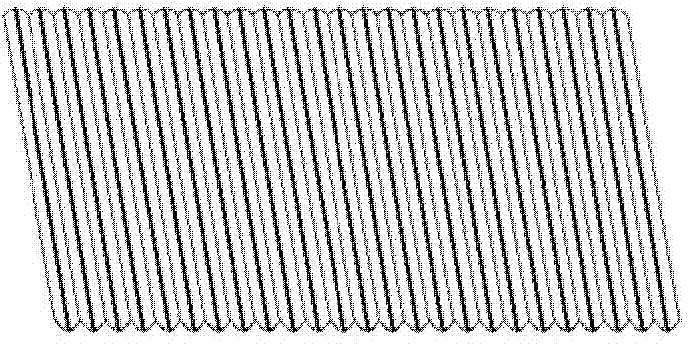

[0030] The spring wire chain is composed of platinum / tungsten alloy wire with good biocompatibility and degradable material polyglycolic acid / polylactic acid copolymer (PLGA). After PLGA is melted at high temperature, it is coated on the periphery of platinum / tungsten alloy wire by extrusion to form a spring wire chain. The diameter of the entire spring wire chain is 0.002″ (inch). The platinum / tungsten alloy wire accounts for 10% of the entire spring wire chain by volume, and the diameter is 0.0002″. A platinum / tungsten alloy wire makes the coil visible under X-rays. The first-stage spring of the spring ring is wound on a metal mandrel with a diameter of 0.003″ by a spring winding machine. The first-stage spring is as follows: figure 1 shown. Then the first-stage spring structure is wound around a 10mm stainless steel mandrel or a 10mm three-dimensional mold to form a basket, shaped and heat-treated, and implanted into the aneurysm by electrolysis. The embolization effect a...

Embodiment 2

[0032] The spring wire chain is composed of platinum / tungsten alloy wire with good biocompatibility and degradable material polyglycolic acid / polylactic acid copolymer (PLGA). After PLGA is melted at high temperature, it is coated on the periphery of platinum / tungsten alloy wire by extrusion to form a spring wire chain. The diameter of the entire spring wire chain is 0.0008″. The platinum / tungsten alloy wire accounts for 8% of the volume of the entire spring wire chain, and the diameter is 0.00008″. A platinum / tungsten alloy wire makes the coil visible under X-rays. The first-stage spring of the spring ring is wound on a metal mandrel with a diameter of 0.020 "with a spring winding machine. The first-stage spring is as follows: figure 1 shown. Then the first-stage spring structure is wound around a 1mm stainless steel mandrel or a 1mm three-dimensional mold to form a basket, heat-treated for shaping, the size is determined according to the size of the aneurysm, and the aneur...

Embodiment 3

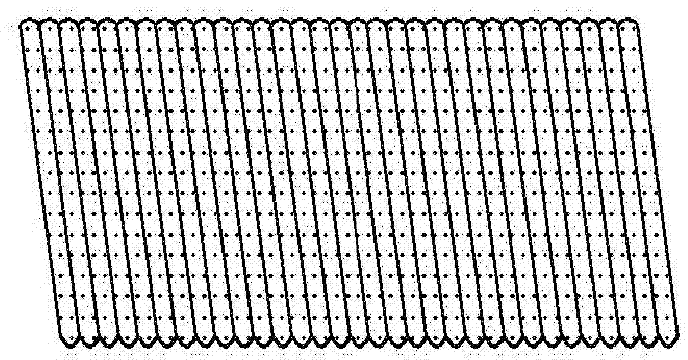

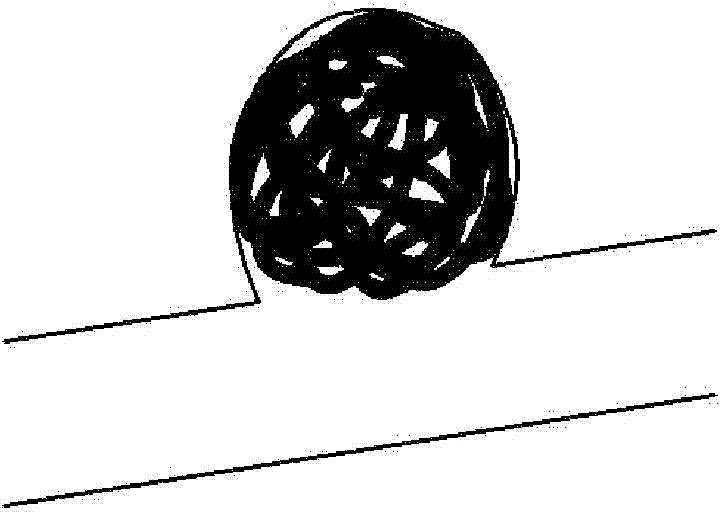

[0034] The spring wire chain is composed of radiopaque iodide and the degradable material polyglycolic acid / polylactic acid copolymer (PLGA). After the PLGA particles are melted at high temperature, silk chains are formed by high temperature melt spinning. The silk chain is soaked in iodide (iodized oil) and dried to form a whole. The diameter of the whole spring wire chain is 0.0015 ". The volume ratio of iodide is 1%, which makes the coil visible under X-ray development. The first-stage spring of the coil is wound on a metal with a diameter of 0.007 " by a spring winding machine It is wound on the mandrel, and the primary spring is as figure 2 shown. Others are the same as the specification, heat treatment process and release method used in Example 1. With the degradation of biomaterials, the aneurysm will gradually shrink, and finally shrink to less than 1% of its original size, and even reach 0%. Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com