A density board produced by using soybean protein glue and its preparation method

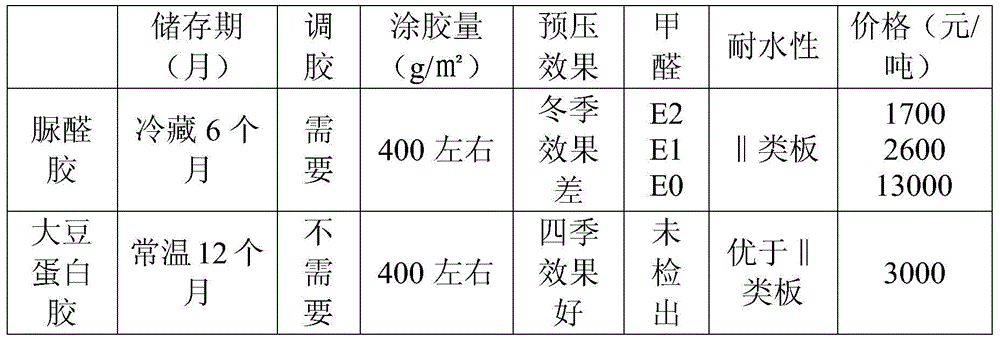

A technology of soybean protein glue and density board, which is applied in applications, household components, flat products, etc., can solve problems such as harming health, limiting the scope of use, and poor waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A density board produced by using soybean protein glue and a preparation method; material preparation→air delivery→fiber separation→glue sizing and drying→pavement molding→prepressing→hot pressing→cooling board→edge trimming→sanding→separate inspection and storage. The bonding colloid is soybean protein glue, and the preparation of soybean protein glue includes: 30 parts of soybean protein raw materials, 100 parts of water, 25 parts of modifier, 10 parts of filler, 2 parts of thickener, anionic surfactant 3 parts, preservative 2 parts; soybean protein glue does not contain formaldehyde, green and environmentally friendly, non-toxic and harmless, and the volatility of protein adhesives is particularly low, no degumming, bonding strength and water resistance can meet the technical indicators of urea-formaldehyde resin . The density board made is non-toxic, harmless, green and environmentally friendly, and its formaldehyde emission is zero.

Embodiment 2

[0028] A method for preparing a density board produced by soybean protein glue, comprising the following steps;

[0029] Step 1), material preparation section:

[0030] The raw materials are all transported by cutting and loading machine: wood chips and broad-leaved materials are put into the silo in proportion, discharged quantitatively, transported by belt, magnetically separated, and then enter the storage hopper of the thermal mill.

[0031] Step 2), fiber preparation and drying:

[0032] The fiber preparation adopts a vertical preheating cylinder, and the manufactured fiber is directly sprayed into the airflow drying system by the heat refiner, so that the wet fiber is dried to the required moisture content, and the drying heat source is steam. The dried fibers are sent to the fiber warehouse by air after continuous weighing and moisture content determination. In order to ensure the drying quality, the drying system is equipped with a temperature control feedback system...

Embodiment 3

[0057] Embodiment 3: wherein the step 3 of embodiment 2) is: sizing:

[0058] Pipeline sizing is used; the preparation of soybean protein glue includes 50 parts of soybean protein raw materials, 100 parts of water, 35 parts of modifiers, 10 parts of fillers, 3 parts of thickeners, 5 parts of anionic surfactants, and anti-corrosion 2 doses;

[0059] The automatic glue blending machine mixes the various components of the rubber material in proportion, and sprays them directly into the discharge pipe of the heat refiner through the automatic metering device. The amount of glue applied is 8%-12% of the weight of the finished product. Use a metering pump to inject into the thermal grinder, and the dosage is 1-2% of the weight of the finished product. The sizing system adopts automatic monitoring to ensure the quantitative and uniform sizing.

[0060] The automatic glue adjuster sprays soybean protein glue directly into the discharge pipe of the heat refiner, and the glue amount i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com