Adsorption type thermosensitive cross-linking agent masterbatch and preparation method thereof

It is an adsorption type and adsorption heat technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc. It can solve the problems that the melt processing method is not suitable for preparing masterbatches, so as to reduce thermal degradation and contribution to VOC, prevent adhesion and The effect of uneven dispersion and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

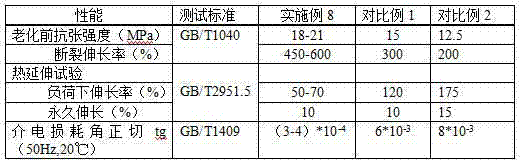

Examples

Embodiment 1

[0028] (1) Put 100 grams of porous polyethylene in a stirring device;

[0029] (2) Spray 900 g of liquid vinyltrimethoxysilane (A171) into polyethylene, and stir at 300 rpm for 60 min at 25 °C to obtain an adsorption-type heat-sensitive crosslinking agent masterbatch.

Embodiment 2

[0031] (1) 500 grams of porous polyurethane is placed in a stirring device;

[0032] (2) Spray 500 g of liquid vinyltriethoxysilane (A151) into polyurethane, and stir at 20 rpm for 60 min at 100 °C to obtain an adsorption-type heat-sensitive crosslinking agent masterbatch.

Embodiment 3

[0034] (1) 300 grams of porous polypropylene is placed in a stirring device;

[0035] (2) Spray 700 g of liquid γ-aminopropyltriethoxysilane (KH550) into porous polypropylene, and stir at 100 rpm for 30 min at 100°C to obtain an adsorption-type heat-sensitive crosslinking agent master grain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com