Methanol-diesel oil additive and preparation method thereof

An additive and methanol technology, applied in the field of methanol diesel additive and its preparation, can solve the problems such as the methanol diesel additive technology has not been solved well, the methanol diesel has not solved the stability, the original structure of the power vehicle, etc., and can achieve strong economy. and social benefits, good power performance, and high combustion calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

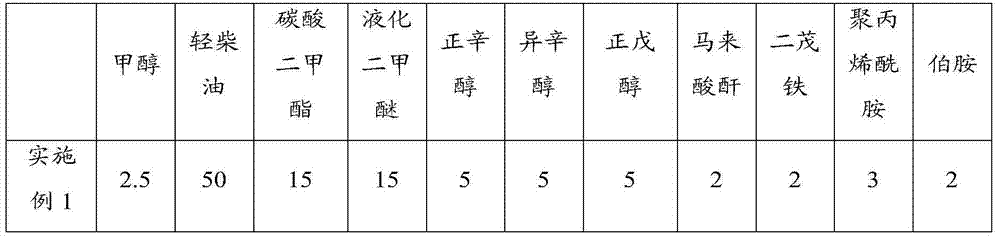

[0027] The raw material composition and proportion of methanol diesel additive are shown in the following table:

[0028] Table 1 Composition and dosage of raw materials

[0029] Unit:kg

[0030]

[0031] The concrete preparation method of methanol diesel additive is as follows:

[0032] Fully dissolve and mix refined methanol and ferrocene in a stirred tank at room temperature to form a homogeneous system to obtain denatured methanol; then add light diesel oil and dimethyl carbonate through a constant pressure funnel to continue stirring and mixing, and finally liquefied dimethyl ether , n-octanol, isooctyl alcohol, n-pentanol, maleic anhydride, primary amine and polyacrylamide were added, and fully stirred to form a homogeneous methanol diesel additive with a clear and transparent appearance. Store at a temperature of 20-25°C.

Embodiment 2

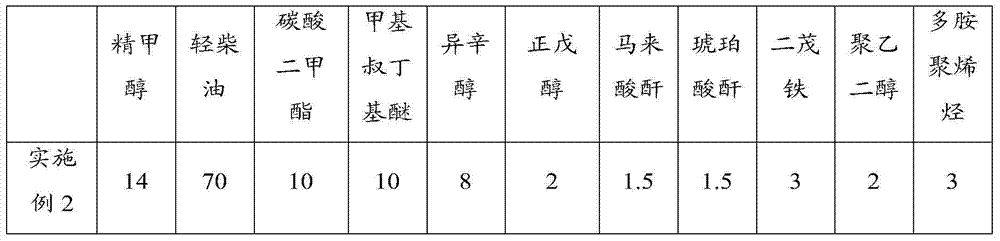

[0034] The raw material composition and proportion of methanol diesel additive are shown in the following table:

[0035] Table 2 Composition and dosage of raw materials

[0036] Unit:kg

[0037]

[0038] The concrete preparation method of methanol diesel additive is as follows:

[0039] Fully dissolve and mix refined methanol and ferrocene in a stirred tank at room temperature to form a homogeneous system, control the stirring rate at 200rad / min, and control the stirring time at 20-25min to obtain denatured methanol; then add light diesel oil in sequence through a constant pressure funnel , dimethyl carbonate continue to stir and mix to form a mixture, now adjust the stirring rate to 300rad / min and stir for 10-15min, and finally methyl tert-butyl ether, isooctyl alcohol, n-amyl alcohol, maleic anhydride, succinic anhydride, Add polyethylene glycol and polyamine polyolefin, and reduce the speed to 200rad / min and fully stir for ...

Embodiment 3

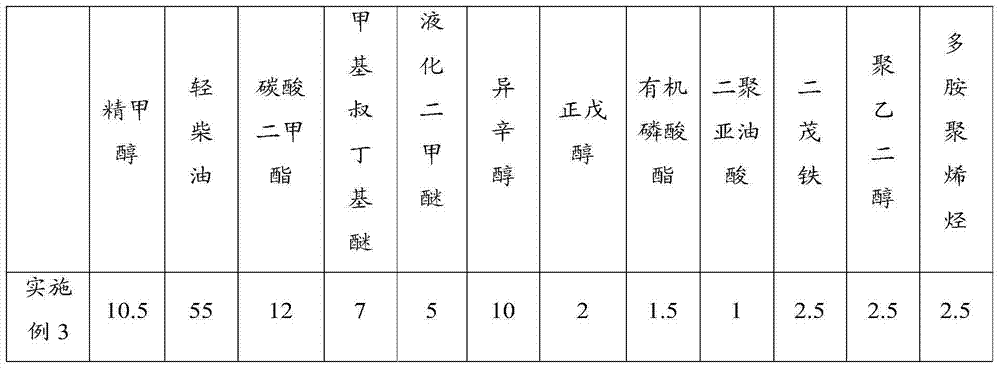

[0041] The raw material composition and proportion of methanol diesel additive are shown in the following table:

[0042] Table 3 Composition and dosage of raw materials

[0043] Unit:kg

[0044]

[0045] The concrete preparation method of methanol diesel additive is as follows:

[0046] Fully dissolve and mix refined methanol and ferrocene in a stirred tank at room temperature to form a homogeneous system, control the stirring rate at 200rad / min, and control the stirring time at 20-25min to obtain denatured methanol; then add light diesel oil in sequence through a constant pressure funnel , dimethyl carbonate continue to stir and mix to form a mixture, now adjust the stirring rate to 300rad / min and stir for 10-15min, finally methyl tert-butyl ether, liquefied dimethyl ether, isooctyl alcohol, n-pentanol, dimer Add linoleic acid, organic phosphate, polyethylene glycol and polyamine polyolefin, and reduce the speed to 200rad / min a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com