System and process for producing natural gas through combined supply of coal and coke-oven gas

A technology for coke oven gas and natural gas, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of difficult wastewater treatment, environmental impact, waste of resources, etc., and achieve the effect of reducing emissions, simplifying processes, and realizing effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific implementation of the system and technology of coal and coke oven gas co-production of natural gas described in the present invention are as follows:

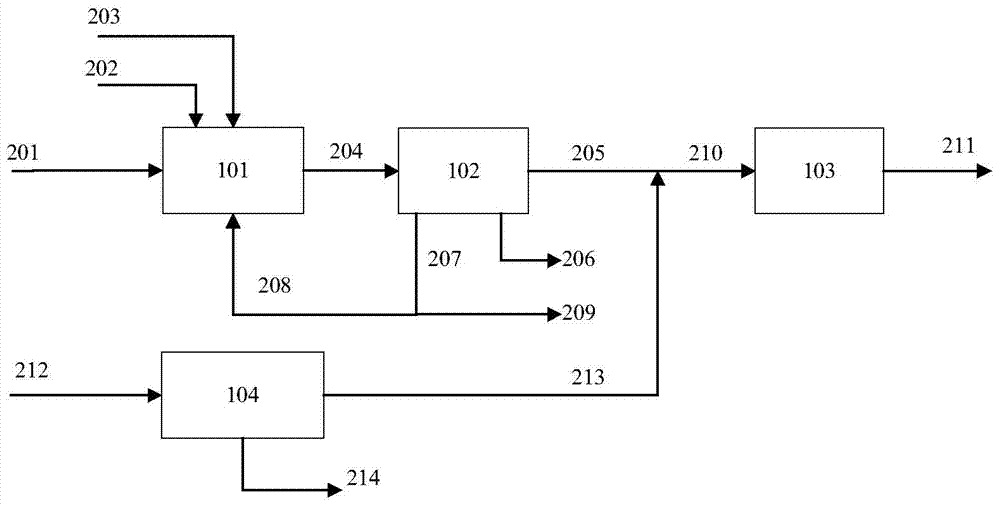

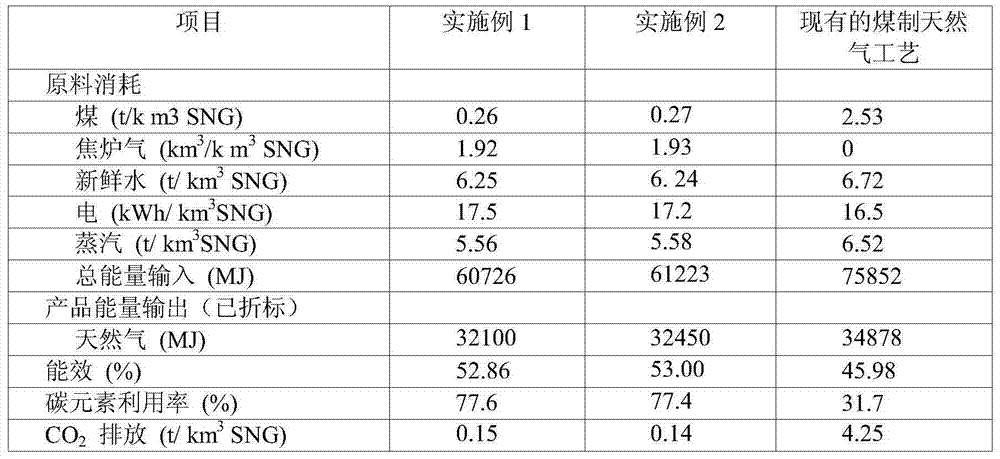

[0039] The flow rate of the raw coal entering the system of coal and coke oven gas joint supply to natural gas is 125t / h, and the flow rate of raw coke oven gas is 348t / h. The composition of crude coke oven gas is shown in Table 1. For a schematic diagram of the system and process for producing natural gas with coal and coke oven gas combined supply, see figure 1 :

[0040] Table 1 Composition of crude coke oven gas

[0041] Element

[0042] After the raw coal 201 is ground into coal powder, it enters the coal gasification unit 101 with water vapor 202 and oxygen 203 for a coal gasification reaction to produce a coal gasification crude synthesis gas 204, and the coal gasification crude synthesis gas 204 enters the acid gas removal unit 102 to The carbon dioxide 207 and sulfide 206 are removed t...

Embodiment 2

[0049] The specific implementation of the system and technology of coal and coke oven gas co-production of natural gas described in the present invention are as follows:

[0050] The flow rate of raw coal entering the system for producing natural gas through coal and coke oven gas combined supply is 100t / h, and the flow rate of raw coke oven gas is 278t / h. The composition of crude coke oven gas is the same as Table 1. For a schematic diagram of the system and process for producing natural gas with coal and coke oven gas combined supply, see figure 1 .

[0051] After the raw coal 201 is ground into coal powder, it enters the coal gasification unit 101 with water vapor 202 and oxygen 203 for a coal gasification reaction to produce a coal gasification crude synthesis gas 204, and the coal gasification crude synthesis gas 204 enters the acid gas removal unit 102 to The carbon dioxide 207 and sulfide 206 are removed to obtain coal gasification synthesis gas 205, the removed sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com