A process for biological desulfurization of high-sulfur coal mines using exclusive desulfurization mixed bacteria

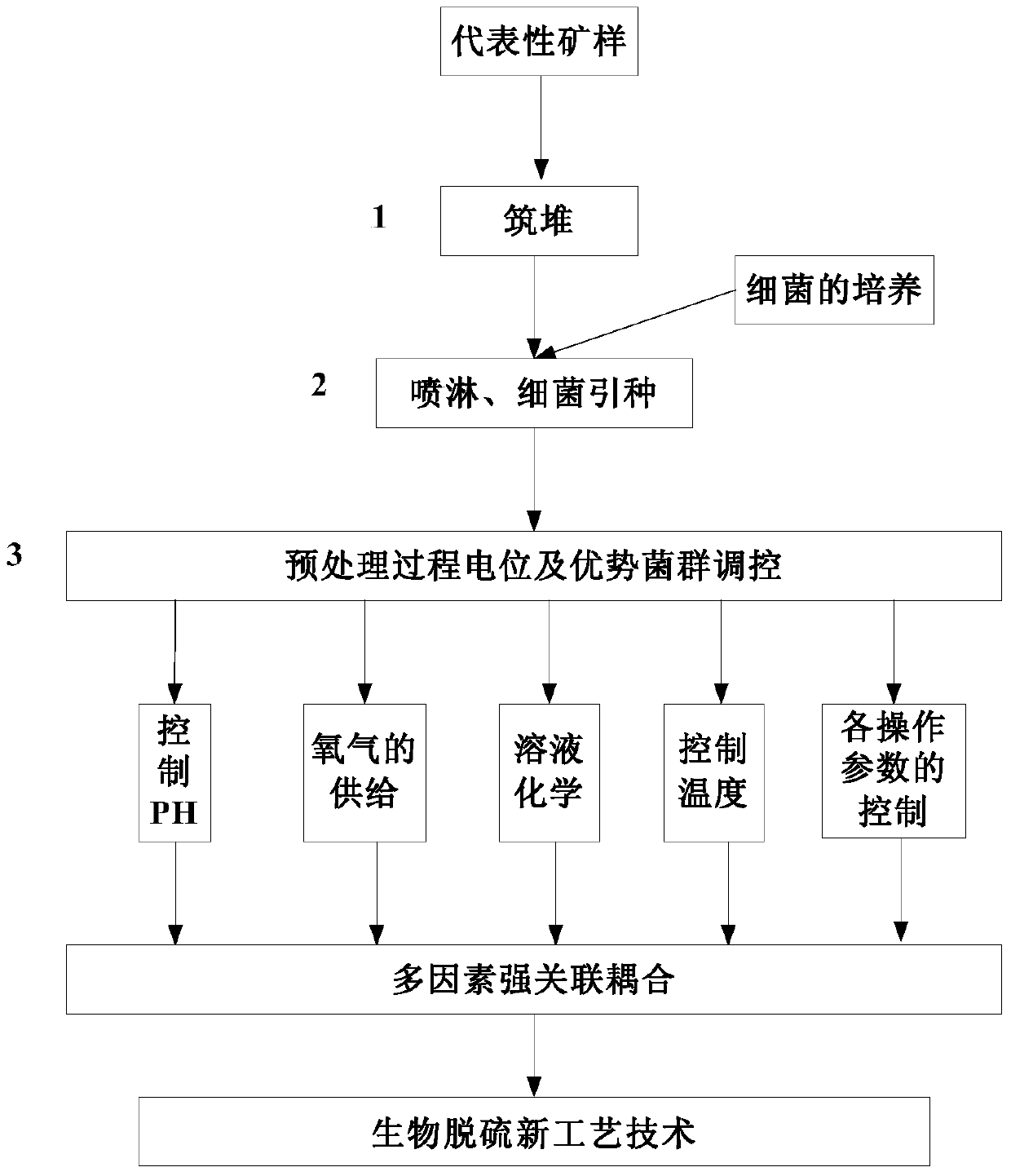

A technology of biological desulfurization and mixed bacteria, which is applied in the field of biological desulfurization of high-sulfur coal mines, can solve the problems of low removal rate, high cost, destruction of chemical structure and performance, etc., and achieves broad application prospects, low cost, and expanded resource utilization. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The coal ore used comes from a sulfur-containing coal mine in Inner Mongolia. The sulfur in the coal ore mainly exists in the form of pyrite, followed by organic sulfur, and the sulfur in the form of sulfate is less. The specific content is shown in Table 1.

[0033] Table 1 Sulfur content in coal mines

[0034]

Total sulfur

pyrite sulfur

organic sulfur

sulfate sulfur

Content / wt%

3.35

2.21

0.82

0.32

[0035] (1) Stacking and paving

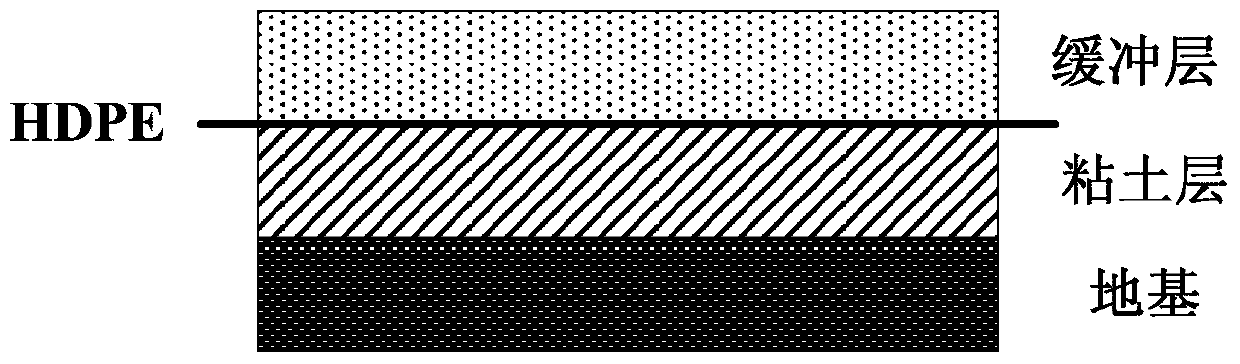

[0036] Before the ore is piled up, operations such as leveling and compaction of the stockyard, anti-seepage bottom pad, and pipeline laying are required; among them, the thickness of the anti-seepage clay layer is not less than 120mm, and the thickness of the ore buffer layer is not less than 800mm. The specific laying procedure is: anti-seepage clay layer-HDPE waterproof layer-fine sand layer-ore buffer layer (buried immersion liquid collection pipe at the same time) and inflatable pipe. ...

Embodiment 2

[0047] The coal ore used comes from a sulfur-bearing coal mine in Outer Mongolia. The sulfur in the coal ore mainly exists in the form of pyrite, followed by organic sulfur and sulfate. The specific content is shown in Table 2.

[0048] Table 2 Sulfur content in coal mines

[0049]

Total sulfur

pyrite sulfur

organic sulfur

sulfate sulfur

Content / wt%

3.02

1.58

0.63

0.81

[0050] (1) Stacking and paving

[0051] Before the ore is piled up, operations such as leveling and compaction of the storage yard, anti-seepage pad, and pipeline laying are required; among them, the thickness of the anti-seepage clay layer is 140mm, and the thickness of the ore buffer layer is 850mm. The specific laying procedure is: anti-seepage clay layer-HDPE waterproof layer-fine sand layer-ore buffer layer (buried immersion liquid collection pipe at the same time) and inflatable pipe. The bottom pad of the yard is generally composed of three parts: the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com