Cyanide-free silver plating solution and electroplating method

A technology of electroplating silver and solution, which is applied in the field of cyanide-free electroplating silver solution and electroplating, and achieves the effects of reasonable formula, good solution stability and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

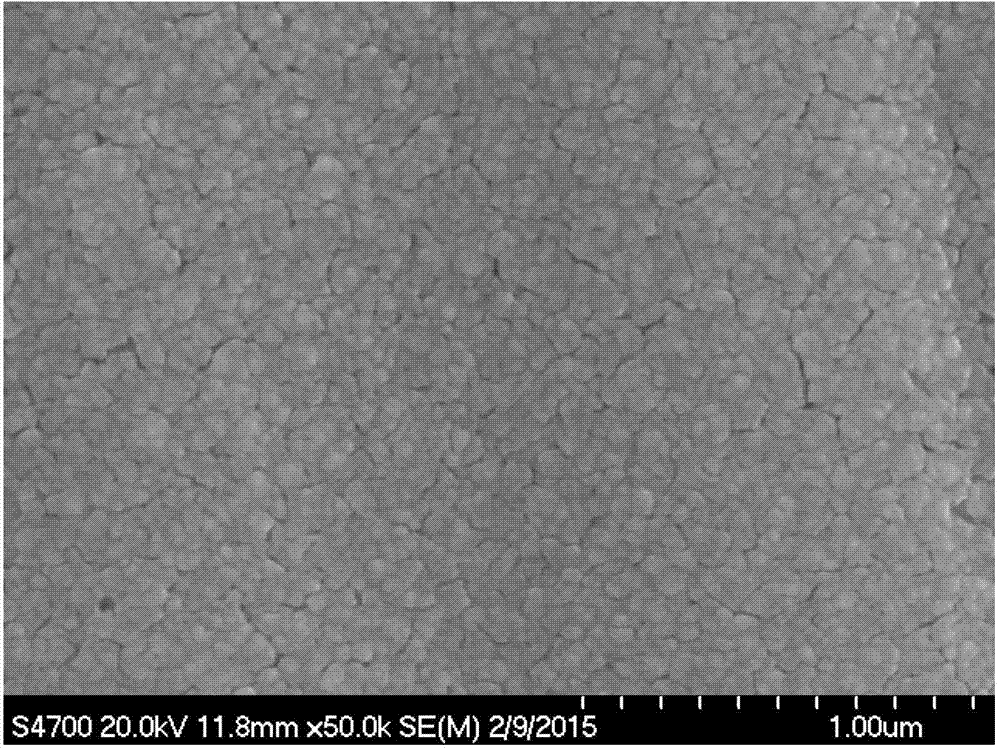

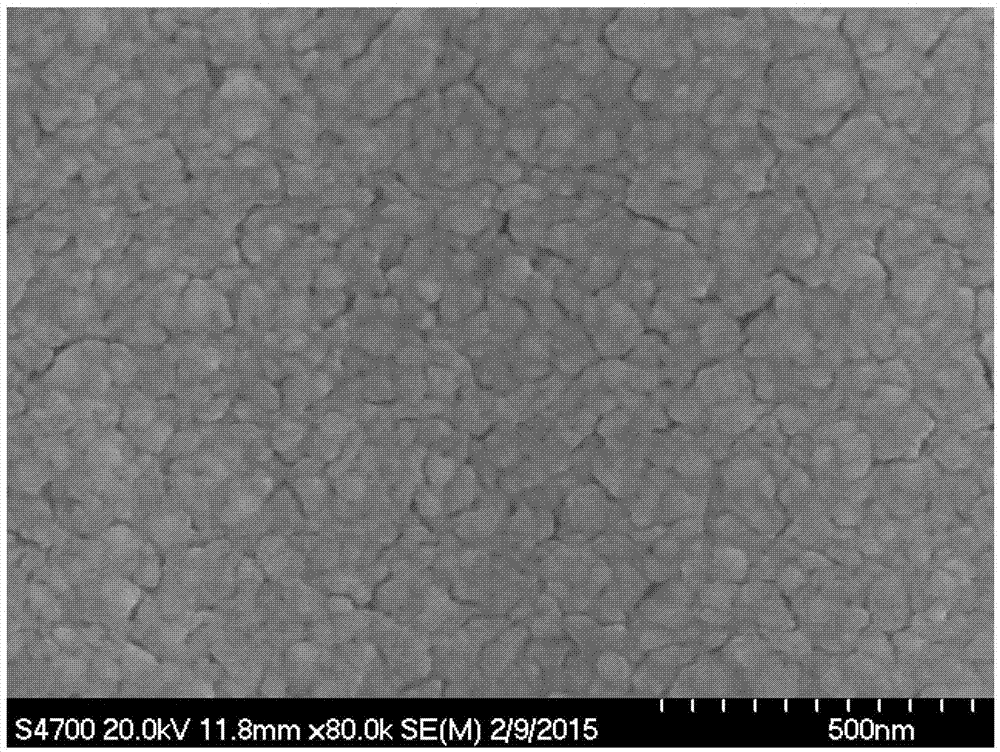

Image

Examples

Embodiment 1

[0025] A kind of cyanide-free electroplating silver solution of the present embodiment 1, be 40g / L silver nitrate, 20g / L disodium edetate, 120g / L succinimide, 20g / L nitric acid, 80g by comprising mass concentration / L potassium hydroxide, 0.06g / L sodium lauroyl sarcosinate and 0.8g / L nicotinamide.

[0026] Adopt the electroplating method of the cyanide-free electroplating silver solution of embodiment 1, as follows:

[0027] Step 1, prepare the cyanide-free electroplating silver solution according to the proportioning mentioned above, and adjust the pH value of the cyanide-free electroplating silver solution to 10.2;

[0028] Step 2. Use the silver plate as the anode and the copper piece (pre-plated piece) as the cathode, control the temperature of the cyanide-free silver plating solution at 25°C to 35°C, use a DC power supply, and control the current density to 1A / dm 2 ; Perform electroplating for 1-5min to obtain an electroplated silver layer on the surface of the copper pi...

Embodiment 2

[0034] A kind of cyanide-free electroplating silver solution of the present embodiment 2, be 50g / L silver nitrate, 40g / L disodium edetate, 160g / L succinimide, 30g / L nitric acid, 100g by comprising mass concentration / L potassium hydroxide, 0.1g / L sodium lauroyl sarcosinate and 10g / L nicotinamide.

[0035] Adopt the electroplating method of the cyanide-free electroplating silver solution of embodiment 2, as follows:

[0036] Step 1, prepare the cyanide-free electroplating silver solution according to the proportioning mentioned above, and adjust the pH value of the cyanide-free electroplating silver solution to 10.2;

[0037] Step 2. Use the silver plate as the anode and the pre-plated parts (such as copper parts) as the cathode, control the temperature of the cyanide-free electroplating silver solution at 25°C to 35°C, use a DC power supply, and control the current density to 1A / dm 2 ; Perform electroplating for 1-5min to obtain an electroplated silver layer on the surface of...

Embodiment 3

[0041] A kind of cyanide-free electroplating silver solution of the present embodiment 3, be 30g / L silver nitrate, 20g / L edetate disodium, 100g / L succinimide, 10g / L nitric acid, 50g by comprising mass concentration / L potassium hydroxide, 0.01g / L sodium lauroyl sarcosinate and 0.1g / L nicotinamide.

[0042] Adopt the electroplating method of the cyanide-free electroplating silver solution of embodiment 3, as follows:

[0043] Step 1, prepare the cyanide-free electroplating silver solution according to the proportioning mentioned above, and adjust the pH value of the cyanide-free electroplating silver solution to 10.2;

[0044] Step 2. Use the silver plate as the anode and the copper piece as the cathode, control the temperature of the cyanide-free electroplating silver solution at 25°C to 35°C, use a DC power supply, and control the current density to 1A / dm 2 ; Perform electroplating for 1-5min to obtain an electroplated silver layer on the surface of the copper piece.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com