System and method for recycling waste heat of air compressor and heating etching chemical liquid by using waste heat

A technology of waste heat recovery and etching liquid medicine, which is applied in the production of other non-combustion heat, heating devices, mechanical equipment, etc., can solve the problems of waste heat waste of air compressors, liquid medicine heating, liquid medicine decomposition, etc., to save production costs and medicines. The effect of high cost and electricity cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

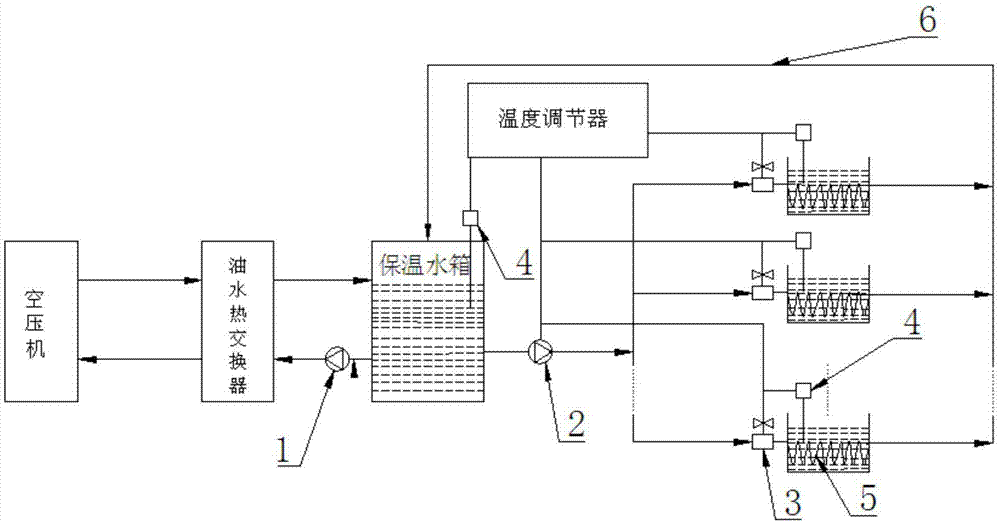

[0039] like figure 1 As shown, on the one hand, the embodiments of the present invention provide an air compressor waste heat recovery and utilization waste heat

[0040] A system for heating etching potion, including an oil-water heat exchanger and an insulated water tank, the hot oil inlet of the oil-water heat exchanger communicates with the hot oil outlet of the air compressor, and the cold oil return outlet of the oil-water heat exchanger It is connected with the cold oil inlet of the air compressor; the air compressor is a screw air compressor.

[0041] The hot water outlet of the oil-water heat exchanger communicates with the hot water inlet of the thermal insulation water tank, the cold return water outlet of the thermal insulation water tank communicates with the cold water inlet of the oil-water heat exchanger, and connects to There is a first circulating water pump 1; the communication pipes between each device can adopt thermal insulation pipes.

[0042] The hot ...

Embodiment 2

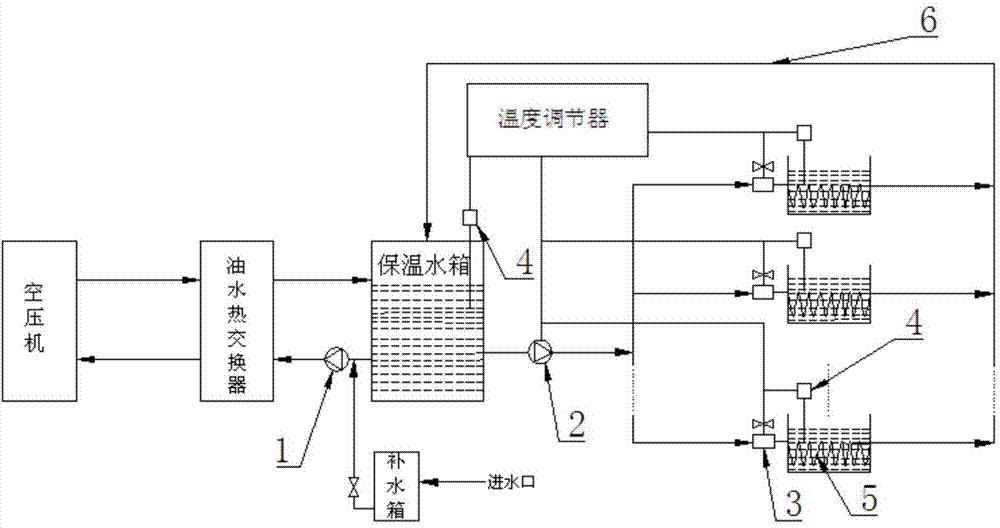

[0056] like figure 2 As shown, the difference from Example 1 is that a replenishment water tank is connected to the heat preservation water tank, and when the water in the heat preservation water tank is insufficient, the heat preservation water tank is replenished, and a check valve is also arranged on the water outlet pipeline of the water replenishment tank.

Embodiment 3

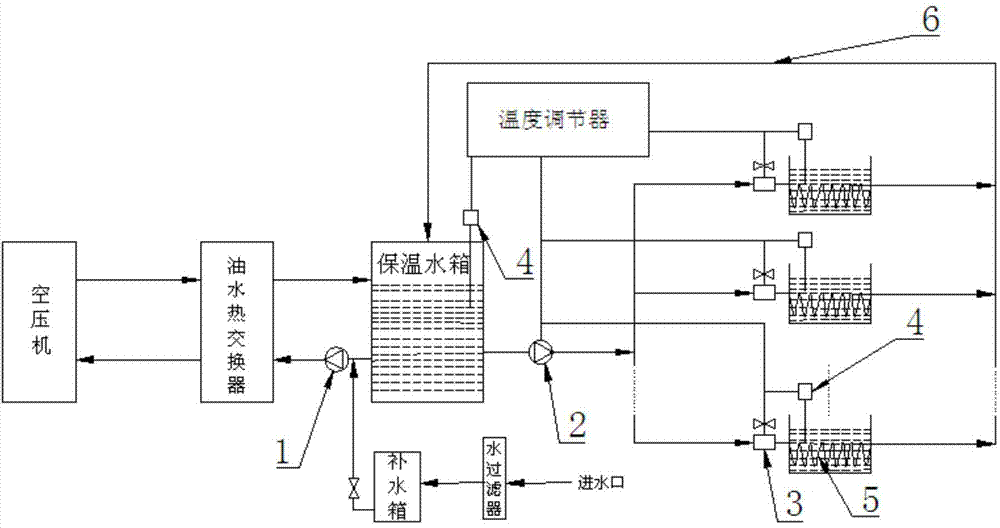

[0058] like image 3 As shown, the difference from Embodiment 2 is that a water filter is added at the water inlet of the replenishment tank.

[0059] In the embodiment of the present invention, the waste heat of the air compressor is stored in the form of hot water at 70-80°C to obtain free heat energy at a temperature between 70-80°C, and this part of the heat energy stored in the form of hot water, Through the insulation pipeline, it is transported to the potion tank of the PCB etching line, browning line, copper sinking line, developing line, etc. that need to be heated, or other hardware surface treatment processes, or other product surface treatment processes. Through the water and the water heat exchanger, the chemical medicine or solution in the above process, or the water used for cleaning is exchanged for heat.

[0060] For example, the electric heating pipe (or steam heating produced by diesel, gas, and coal combustion) equipped with a standard PCB sinking copper w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com