Color planar display thin film controlled by carbon quantum dot concentration and manufacturing method thereof

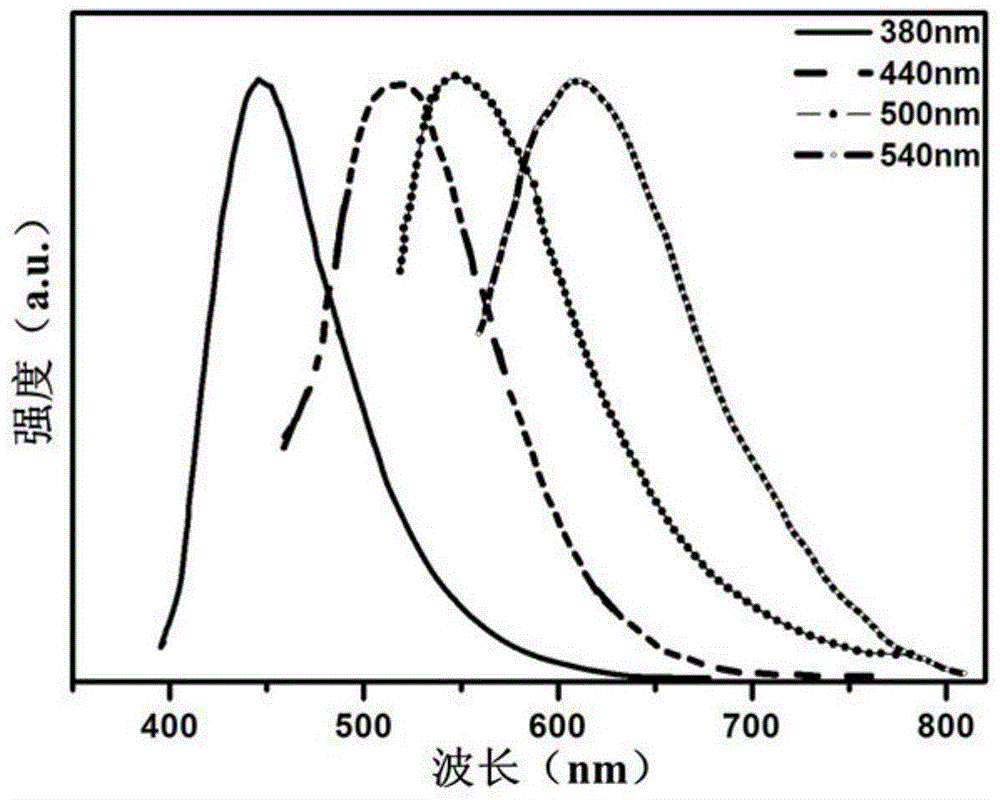

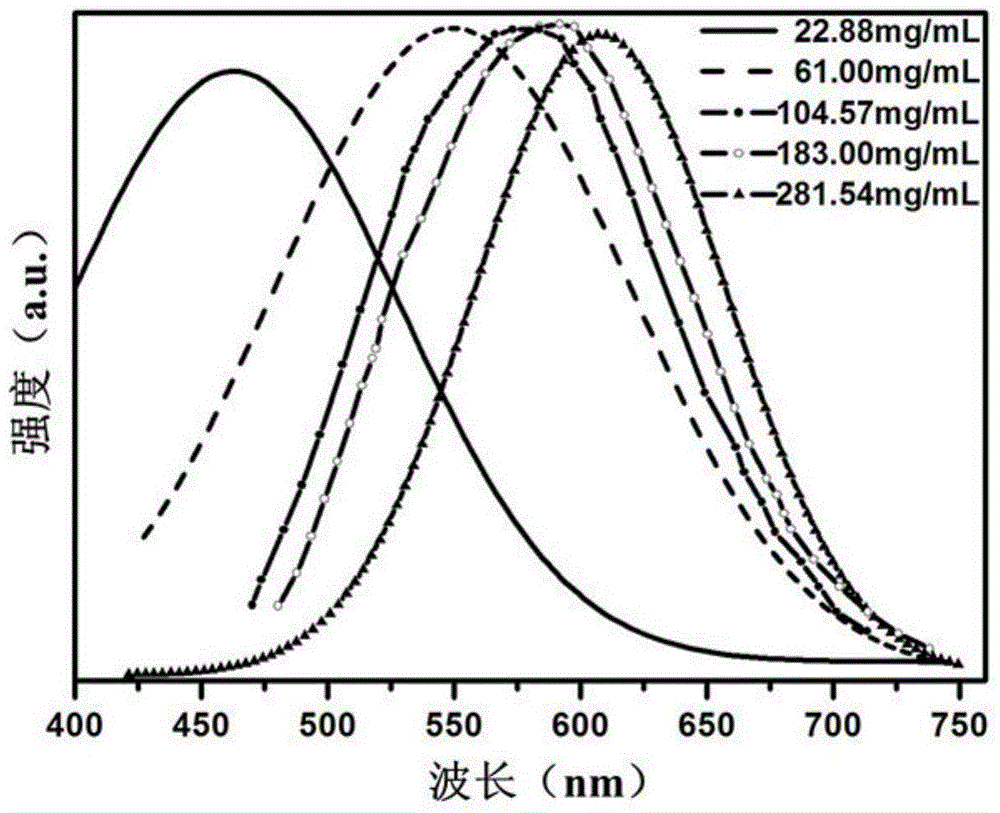

A technology of carbon quantum dots and color plane, which is applied in the field of plane display film and production, can solve the problems of serious heavy metal pollution, single luminous color, and high price, and achieve the effects of low preparation cost, high light saturation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0039] Specific examples of the color flat display film controlled by the concentration of carbon quantum dots in the present invention and the manufacturing method thereof are as follows, but the protection scope of the present invention is not limited to the following examples.

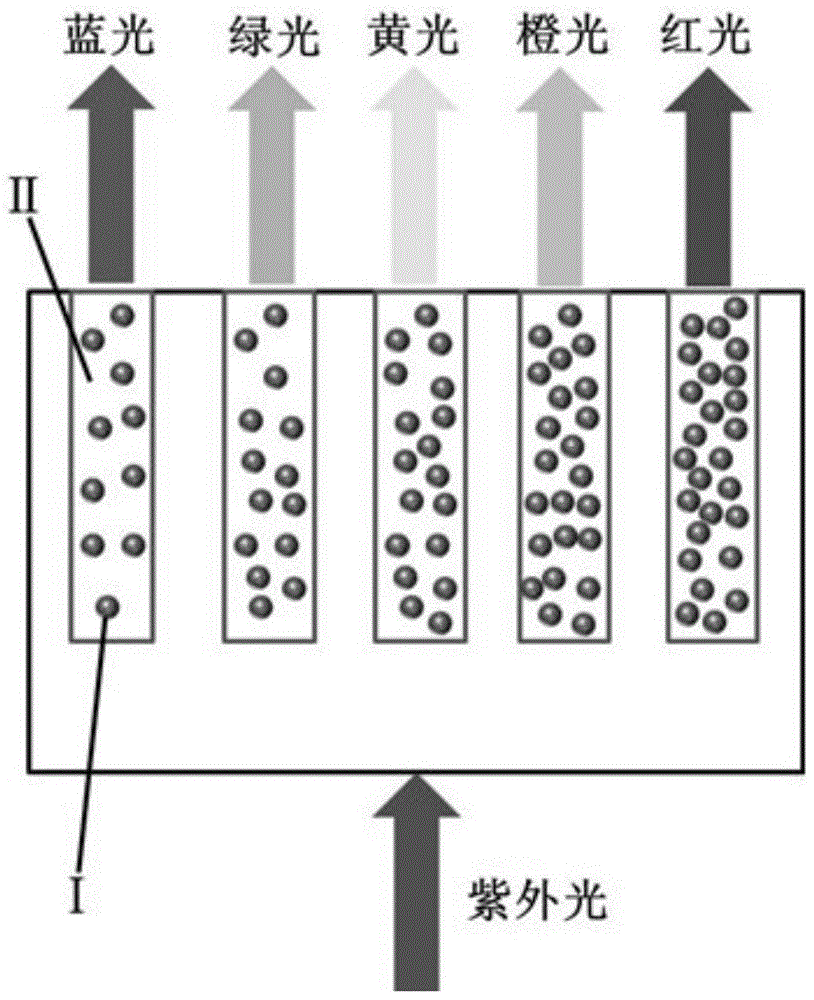

[0040] Such as Figure 4 , Figure 5 As shown, the color flat display film controlled by carbon quantum dot concentration is mainly composed of a heat dissipation substrate, an ultraviolet light source layer, and a carbon quantum dot light-emitting layer; the ultraviolet light source layer is composed of an ultraviolet light-emitting device 5, two electrodes 3, and a gold wire 4 Composition, the ultraviolet light emitting device 5 and two electrodes 3 are mounted on the heat dissipation substrate 1, the two electrodes 3 are respectively located on both sides of the ultraviolet light emitting device 5, gold wires 4 connect the two electrodes 3, the ultraviolet light emitting device 5, and the ultraviolet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com