Rare earth ion Tb < 3 + > doped LiTaO3 multiband emission pressure luminescent material and preparation method and application thereof

A technology of rare earth ions and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of increased manufacturing costs, complex synthesis conditions, and reduced optical properties, and achieves easy control of preparation conditions, simple preparation process, and high luminous intensity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

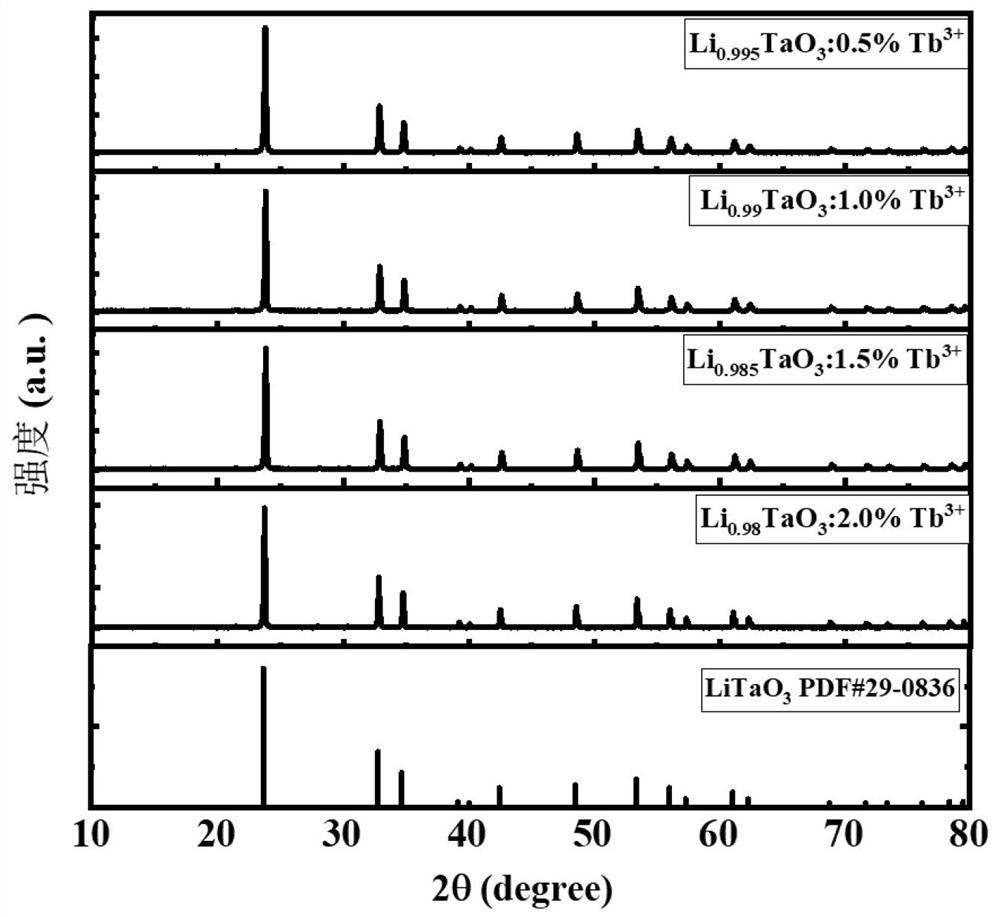

[0040] According to the molar ratio of each element Li:Ta:Tb=0.995:1:0.005 (equivalent to Tb doping amount x=0.005), lithium carbonate, tantalum oxide and tetraterbium heptoxide were selected as raw materials, and the weighing amount was 0.3676g , 2.2097g and 0.0094g. Fully grind in an agate mortar for 1 hour to make it mix uniformly to obtain a mixed powder. Put the mixed powder into a muffle furnace, raise the temperature from room temperature to 600°C at a rate of 5°C / min, pretreat for 2 hours in an air atmosphere, and obtain calcined powder after cooling. Grind the calcined powder again, put it into a muffle furnace from room temperature to a calcination temperature of 1100°C at a rate of 3°C / min, calcinate in an air atmosphere for 5 hours, and cool to room temperature with the furnace to obtain Li 0.995 TaO 3 :0.005Tb 3+ (x=0.005) pressure luminescence powder. The synthetic powder has high crystallinity, see figure 1 The XRD diffraction phase analysis results shown. ...

Embodiment 2

[0042] On the basis of Example 1, increase Tb 3+ Doping amount. According to the molar ratio of each element Li:Ta:Tb=0.99:1:0.01 (equivalent to Tb doping amount x=0.01), lithium carbonate, tantalum oxide and tetraterbium heptoxide were selected as raw materials, and the weighing amount was 0.3621g , 2.2097g and 0.0187g were fully ground in an agate mortar for 1 hour, and mixed evenly to obtain a mixed powder. Put the mixed powder into a muffle furnace, raise the temperature from room temperature to 600°C at a rate of 5°C / min, pretreat for 2 hours in an air atmosphere, and obtain calcined powder after cooling. Grind the calcined powder again, put it into a muffle furnace from room temperature to a calcination temperature of 1100°C at a rate of 3°C / min, calcinate in an air atmosphere for 5 hours, and cool to room temperature with the furnace to obtain Li 0.990 TaO 3 :0.01Tb 3+ (x=0.01) pressure luminescent powder. The synthetic powder has high crystallinity, see figure 1 ...

Embodiment 3

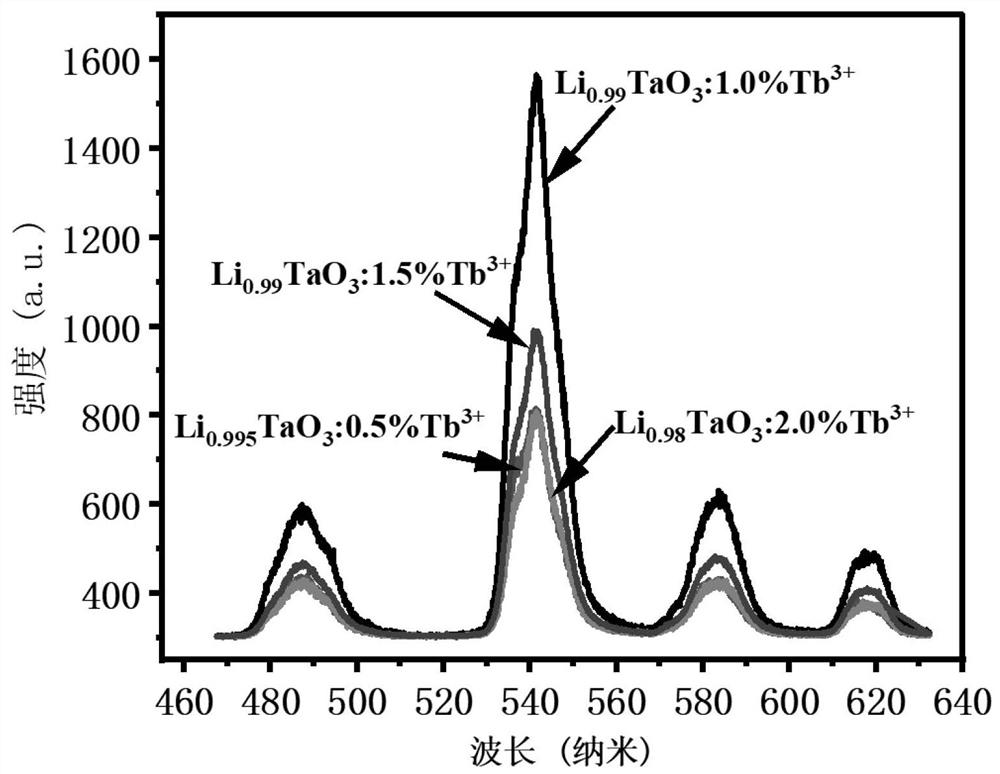

[0044] Rare earth ion Tb in the present embodiment 3 3+ Doped LiTaO 3 The preparation process of the multi-band emission piezoluminescent material is referred to Example 2, the difference is: x=0.015. See figure 1 The XRD diffraction phase analysis results shown. It is detected that the pressure luminescent material prepared in Example 3 has a luminous emission peak of a line spectrum under a pressure of 2000N, and has blue light emission at 487nm, green light emission at 541nm, and yellow light emission at 583nm. and orange emission at 618nm, see figure 2 The results of pressure emission spectroscopy are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com