Solid electrolyte material with low interface impedance and preparation method of solid electrolyte material

A solid electrolyte and interface impedance technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as reducing the interface impedance of electrolyte materials, and achieve the effects of avoiding damage, reducing interface impedance, and increasing battery impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

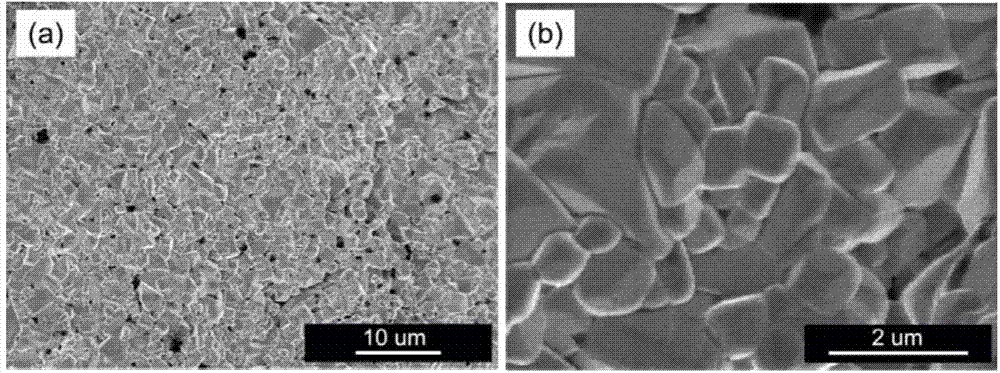

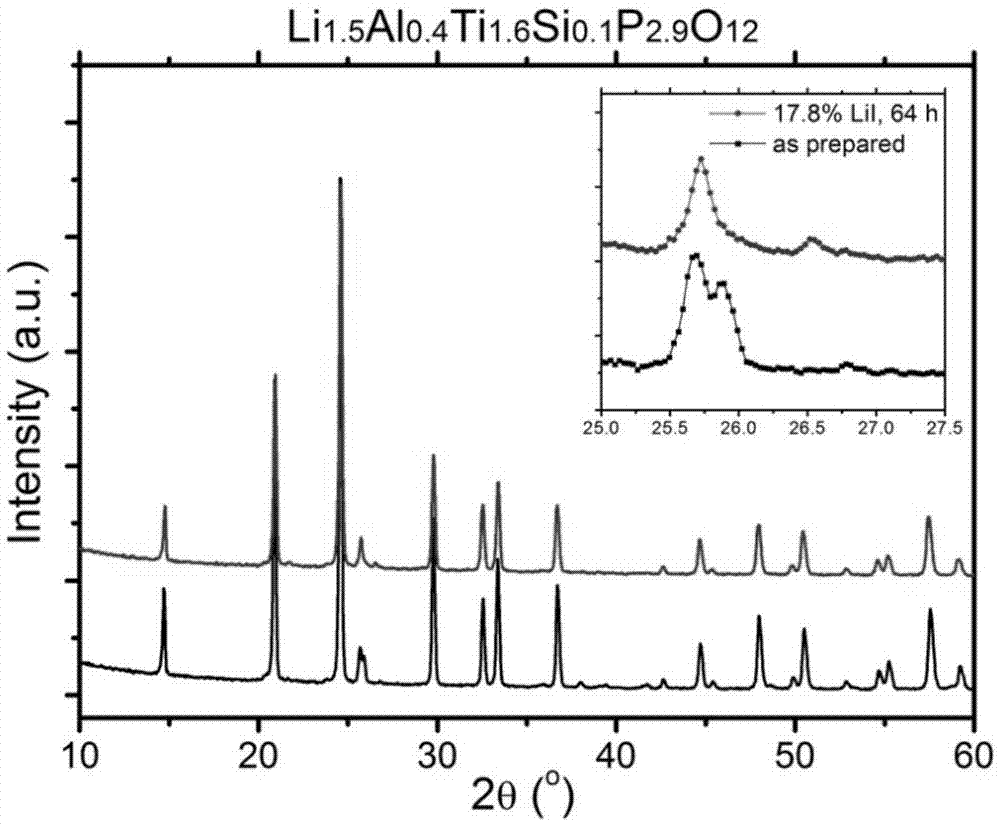

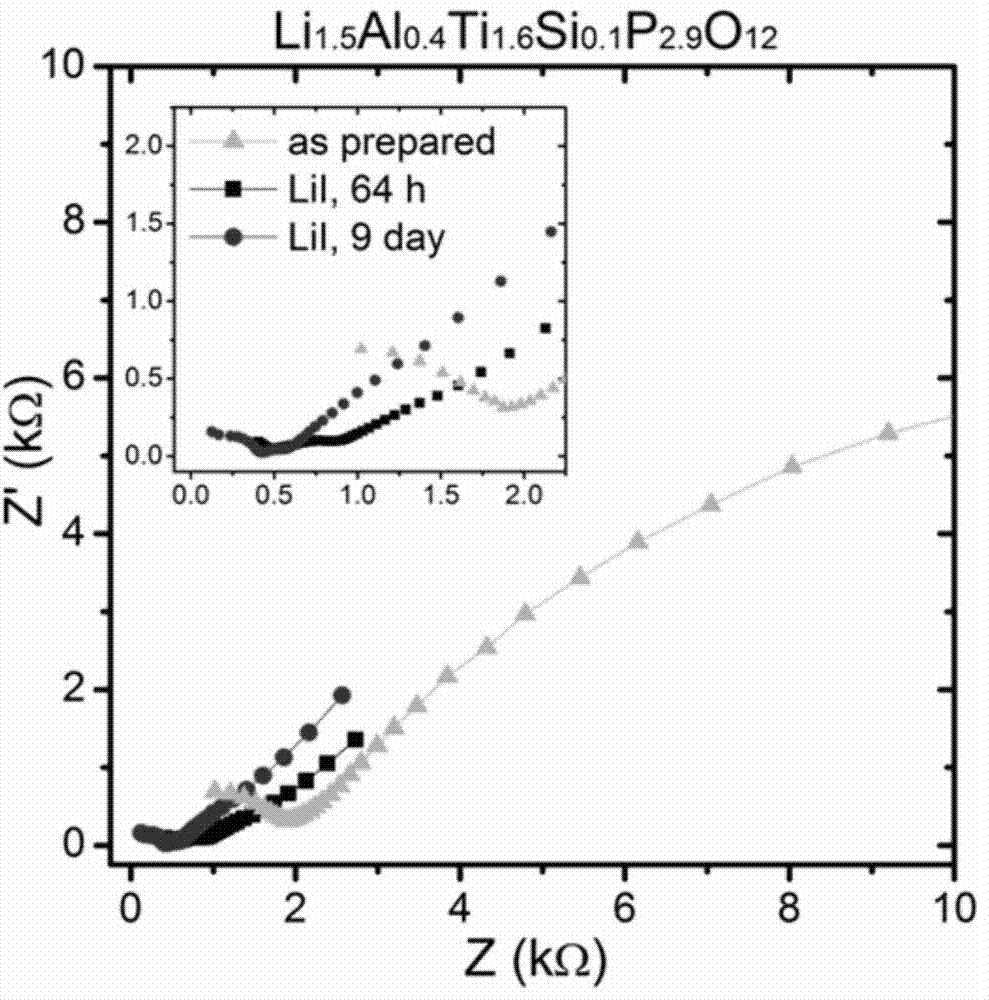

[0036] With Li 1.5 Al 0.4 Ti 1.6 Si 0.1 P 2.9 o 12 Weigh the stoichiometric Li 2 CO 3 , Al(OH) 3 , SiO 2 、TiO 2 , NH 4 h 2 PO 4 , Preliminary mixing was carried out by a planetary ball mill (ball milling speed: 500rpm, ball milling method: forward and reverse alternating each 0.1h, interval 0.2h, cycle 3 times), using Ar as the carrier gas, heat treatment at 700°C for 2h to remove volatile impurities. After grinding and crushing, put it in a polytetrafluoro tank, and ball mill at 500rpm for 20h (forward / reverse alternately, each 1h, interval 12min). After taking it out, put the powder in a stainless steel mold with d=22mm, and cold press it under a pressure of 15-24MPa (holding time for 3 minutes), and put the obtained sheet material in a muffle furnace for sintering at 900°C for 6 hours. The heating rate is 5°C / min. The sample after the high-temperature solid phase reaction was taken out, soaked in a 17.8% LiI (mass fraction) solution, and placed in a 50° C. wat...

Embodiment 2

[0038] With Li 1.4 Al 0.4 (Ge 0.2 Ti 0.8 ) 1.6 (PO 4 ) 3 Weigh the stoichiometric Li 2 CO 3 , Al(OH) 3 、GeO 2 、TiO 2 , NH 4 h 2 PO 4 , Preliminary mixing was carried out by a planetary ball mill (ball milling speed: 500rpm, ball milling method: forward and reverse alternating each 0.1h, interval 0.2h, cycle 3 times), using Ar as the carrier gas, heat treatment at 700°C for 2h to remove volatile impurities. After grinding and crushing, put it in a polytetrafluoro tank, and ball mill at 500rpm for 20h (forward / reverse alternately, each 1h, interval 12min). After taking it out, put the powder in a stainless steel mold with d=22mm, and cold press it under a pressure of 15-24MPa (holding time for 3 minutes), and put the obtained sheet material in a muffle furnace for sintering at 850°C for 6 hours. The heating rate is 5°C / min. The sample after the high-temperature solid phase reaction was taken out, immersed in a 17.8% LiI (mass fraction) solution, and placed in a wa...

Embodiment 3

[0040] With Li 1.5 Al 0.4 Ti 1.6 Si 0.1 P 2.9 o 12 Weigh the stoichiometric Li 2 CO 3 , Al(OH) 3 , SiO 2 、TiO 2 , NH 4 h 2 PO 4 , Preliminary mixing was carried out by a planetary ball mill (ball milling speed: 500rpm, ball milling method: forward and reverse alternating each 0.1h, interval 0.2h, cycle 3 times), using Ar as the carrier gas, heat treatment at 700°C for 2h to remove volatile impurities. After grinding and crushing, put it in a polytetrafluoro tank, and ball mill at 500rpm for 20h (forward / reverse alternately, each 1h, interval 12min). After taking it out, put the powder in a stainless steel mold with d=22mm, and cold press it under a pressure of 15-24MPa (holding time for 3 minutes), and put the obtained sheet material in a muffle furnace for sintering at 900°C for 6 hours. The heating rate is 5°C / min. Take out the sample after the high-temperature solid-state reaction, soak it in a saturated LiCl solution, and place it in a 50°C water bath for 70 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com