Soil leaching quality-improvement restoration device with tail gas treatment function

A technology for exhaust gas treatment and soil leaching, which is applied in the field of soil remediation to achieve the effects of improving remediation efficiency, simple structure and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

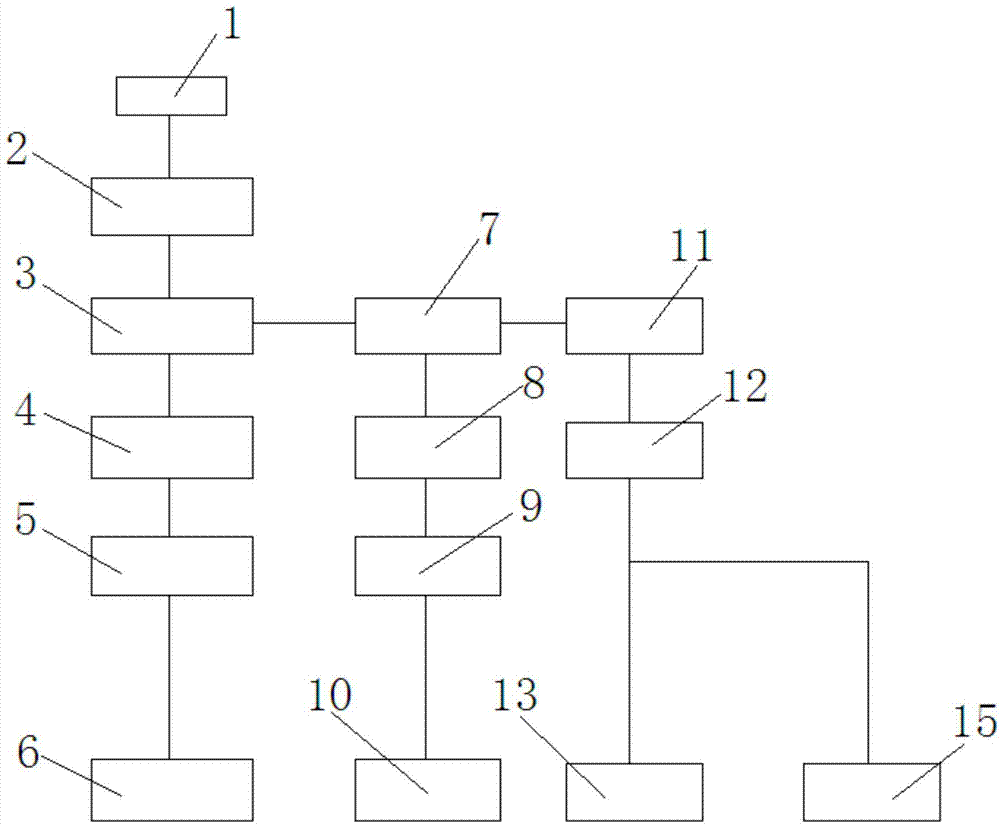

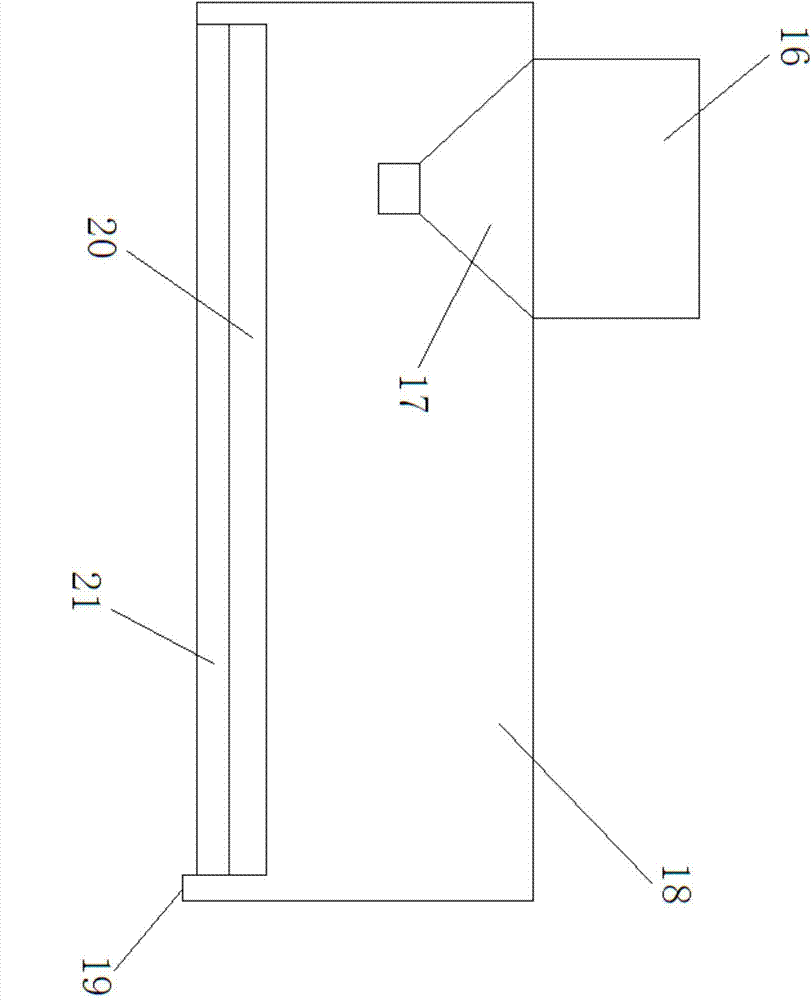

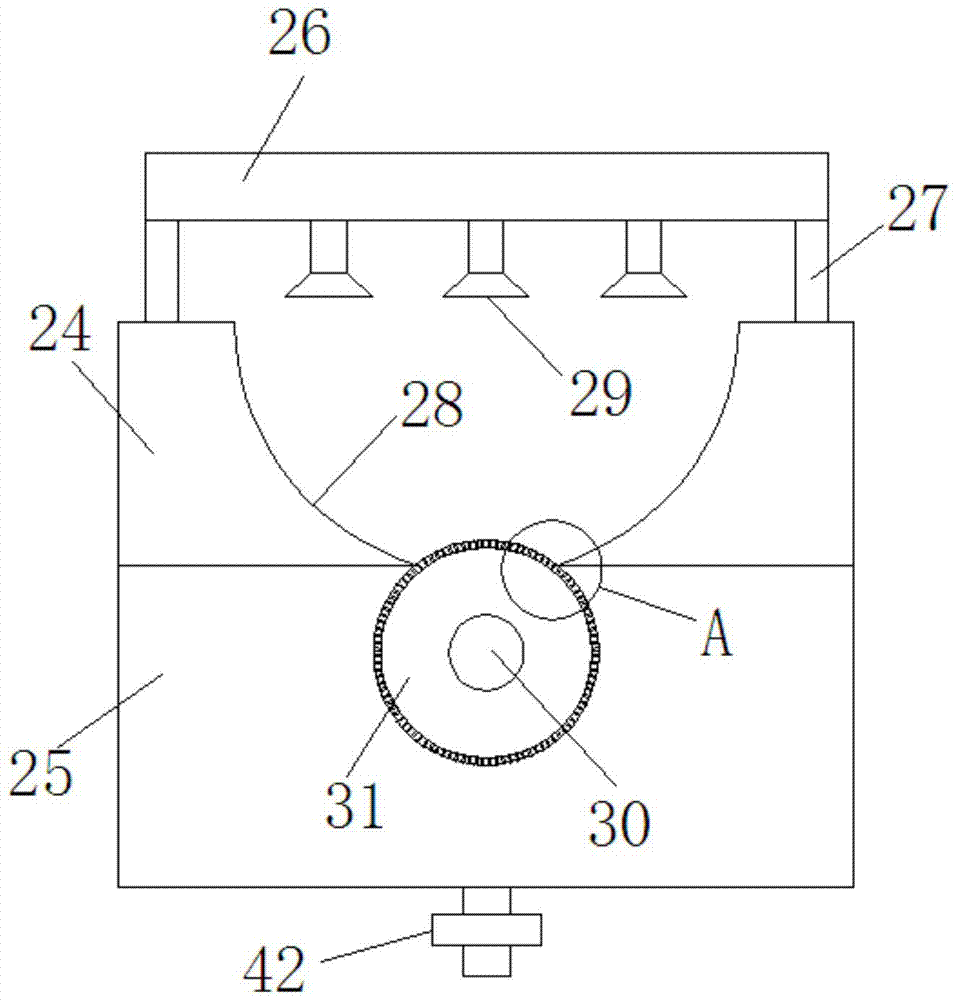

[0024] like figure 1 Shown is a soil leaching and upgrading repair device with tail gas treatment function, including contaminated soil feeding system 1, leaching and separation system 2, solid-liquid separator 3, precipitation reaction system 4, filter press 5, rotary heating System 7, cyclone separator 8, condenser 9, screw excavator 10, dust removal system 11, condensation tower 12, pollutant discharge system 13, tail gas treatment system 14 and gas discharge system 15, the described polluted soil feeding system 1 is connected to the rinsing and separation system 2, the leaching and separation system 2 is connected to the precipitation reaction system 4 and the rotary heating system 7 respectively through the solid-liquid separator 3, and the described precipitation reaction system 4 is connected to the filter press 5, The rotary heating system 7 is respectively connected to the spiral excavator 10 and the dust removal system 11 through the cyclone separator 8, and a conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com