Device and method for detecting gear shape and performance

A gear and performance technology, applied in the direction of feeding devices, measuring/indicating equipment, large fixed members, etc., can solve problems such as being susceptible to external interference, backward gear detection technology, machining errors, tooth contact stiffness and fatigue strength changes, etc., to achieve The effect of lowering the center of gravity of the machine tool, enriching measurement information, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described below in conjunction with accompanying drawing:

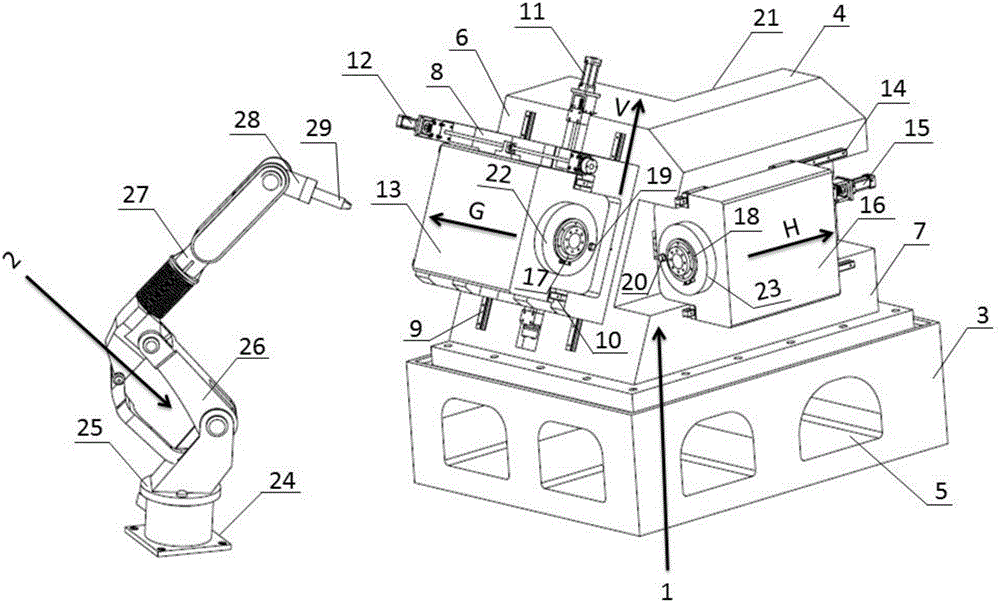

[0033] The structure of the present invention is as figure 1 As shown, the device for detecting the shape and performance of gears includes a high-precision machine tool system (1) and a mechanical arm system (2).

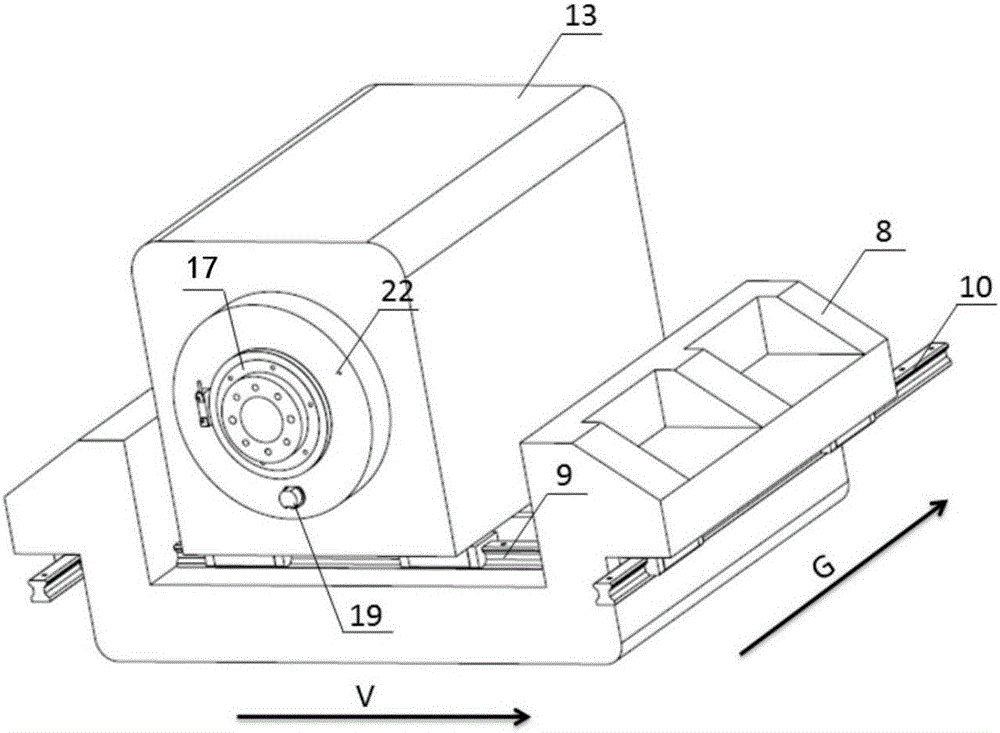

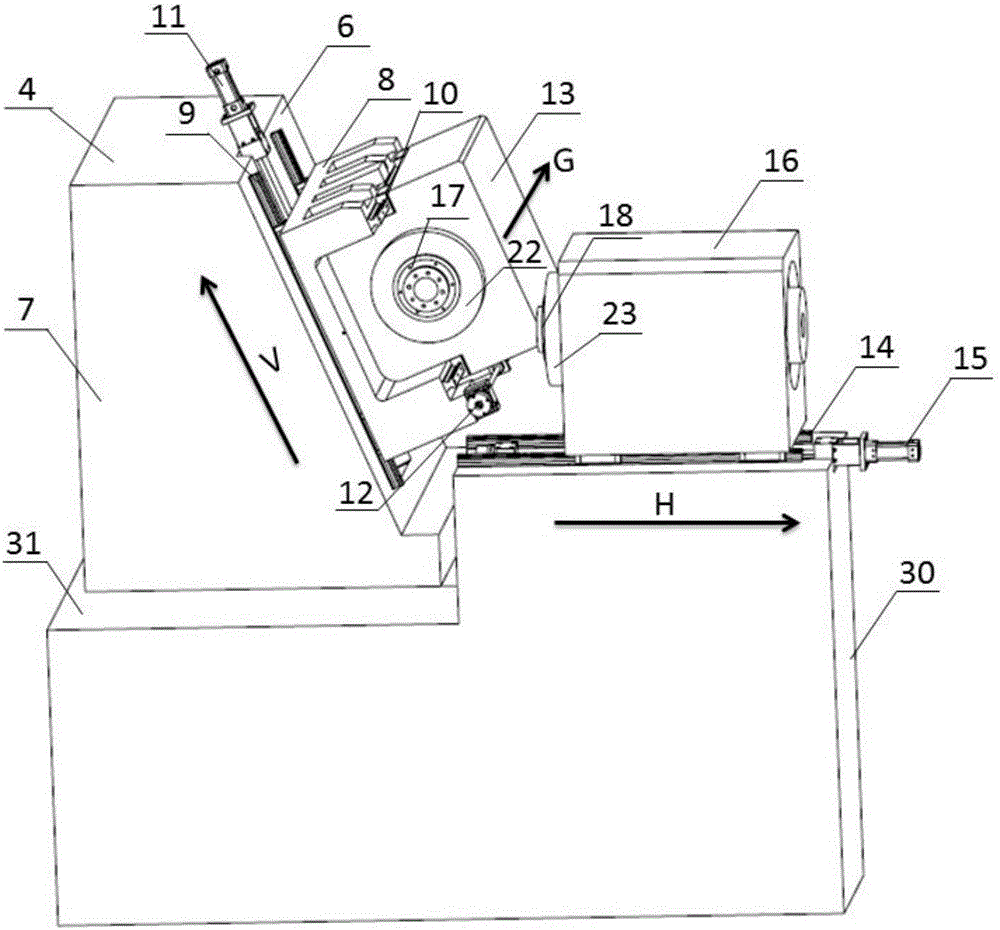

[0034] Specifically, the high-precision machine tool system (1) includes a base (3), an inclined bed (4), a weight reduction hole (5), an inclined surface (6), an adjacent surface of the inclined surface (7), a slide table (8 ), V-guided guide pair (9), G-guided guide pair (10), V-directed screw motor (11), G-directed screw motor (12), first direct drive motor headstock (13), H-guided guide Vice (14), H-direction screw motor (15), second direct drive motor spindle box (16), ring encoder a (17), ring encoder b (18), acceleration sensor a (19), acceleration sensor b (20), groove (21), the first direct drive motor (22), the second direct drive motor (23), L-shaped base (30). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com