Multifunctional assembled 3D printing device and multifunctional assembled 3D printing method

A 3D printing and assembly technology, applied in the field of 3D printing, can solve the problems of low printing speed and single printing form, and achieve the effect of improving printing work efficiency and adaptability to compatible products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

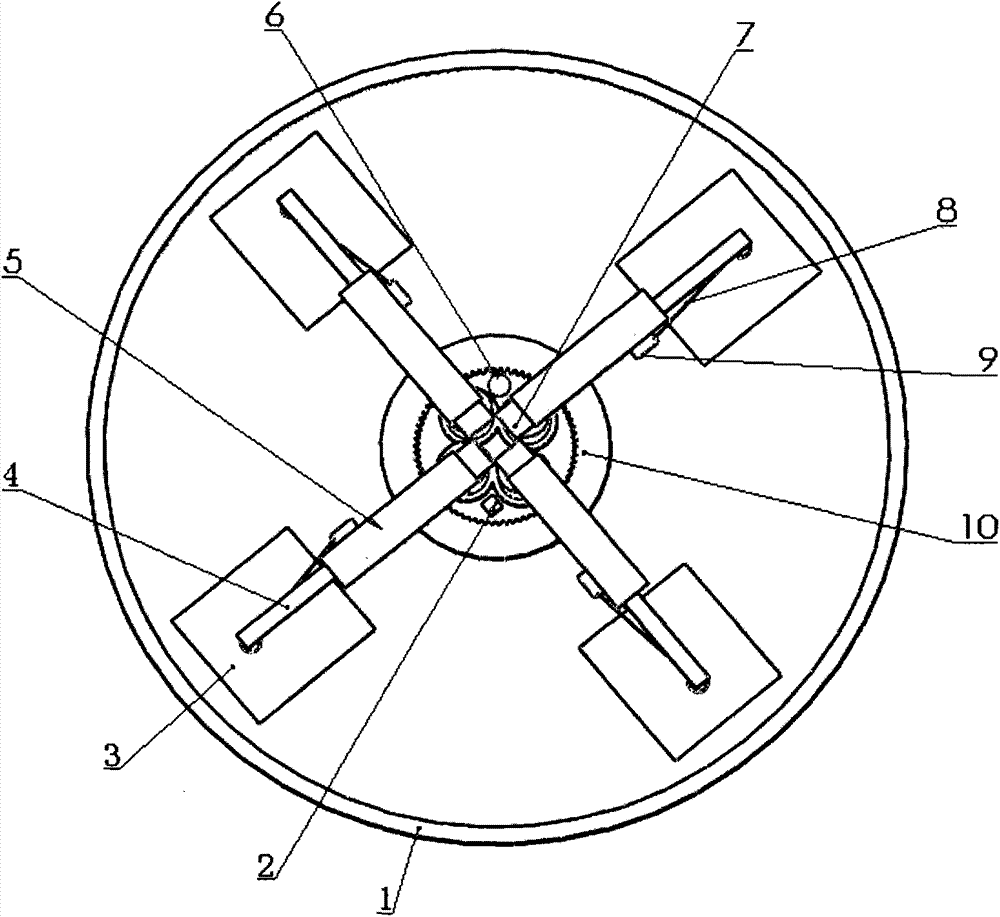

[0031] see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a multifunctional assembled 3D printing device, including a circular chassis 1, a plurality of worktables 3, a rotating motor 6, a gear ring 10, and a single printing component;

[0032] The center of the circular chassis 1 is provided with a mounting hole, the mounting hole is coaxial with the gear ring 10 in the mounting hole, and a plurality of workbenches 3 are fixed at intervals along the circumferential direction (specifically by the workbench bracket 14) on the side wall of the gear ring 10; the rotating motor 6 is used to drive the rotation of the gear ring 10 (it should be noted that since the gear ring is driven to rotate, it can drive a plurality of work fixedly connected on the gear ring side wall table rotation);

[0033] A plurality of monomer printing assemblies are located in the mounting holes, and each monomer printing assembly includes a vertical lift mechanism...

Embodiment 2

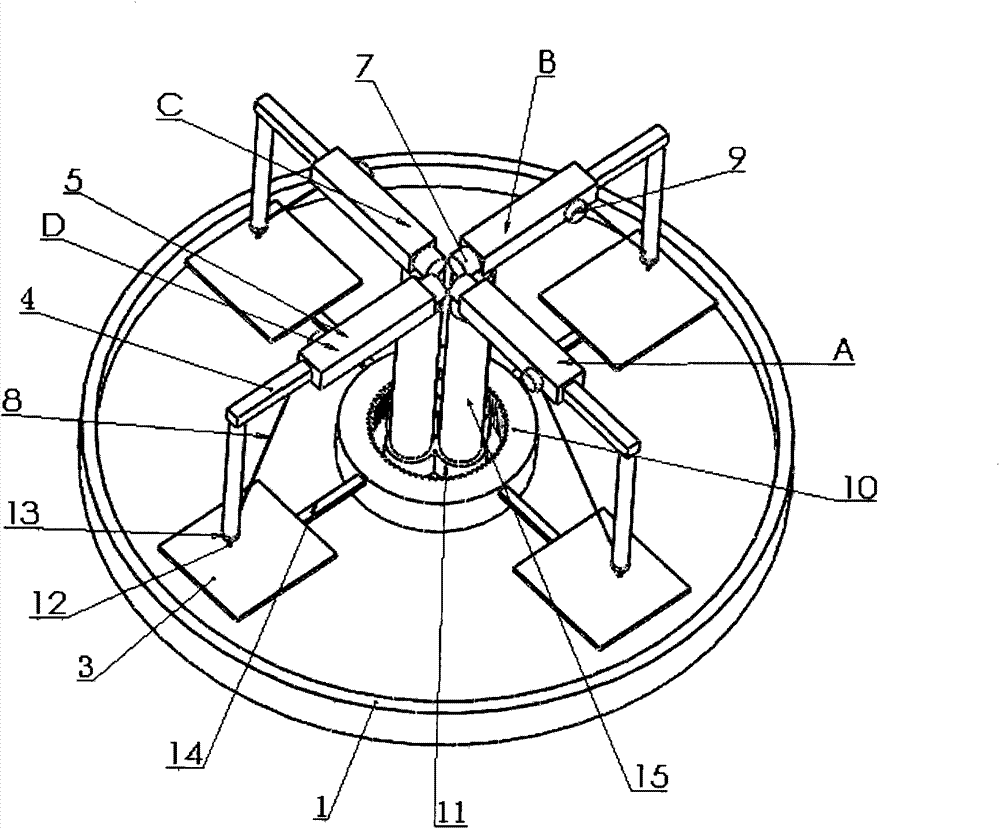

[0060] Such as Figure 4 As shown, the multifunctional assembled 3D printing device includes a circular chassis 1, a hydraulic pump station 2, a plurality of worktables 3, a telescopic rod 4, a second hydraulic cylinder 5, a rotating motor 6, a circular rotating motor 7, and a raw material box 9 , gear ring 10, first hydraulic cylinder 11, second laser generator 12, working support 14, lifting rod 15 photosensitive sheet 16, signal conversion device (built-in first laser generator) 17, vertical lifting mechanism and horizontal telescopic mechanism, etc., wherein, the vertical lifting mechanism and the horizontal telescopic mechanism are hydraulic transmission; the vertical lifting mechanism includes the first hydraulic cylinder 11 and the lifting rod 15; the horizontal telescopic mechanism includes the hydraulic cylinder 5 and telescopic rod 4; the horizontal telescopic mechanism can move on the horizontal plane perpendicular to the radial direction of the circular chassis 1 u...

Embodiment 3

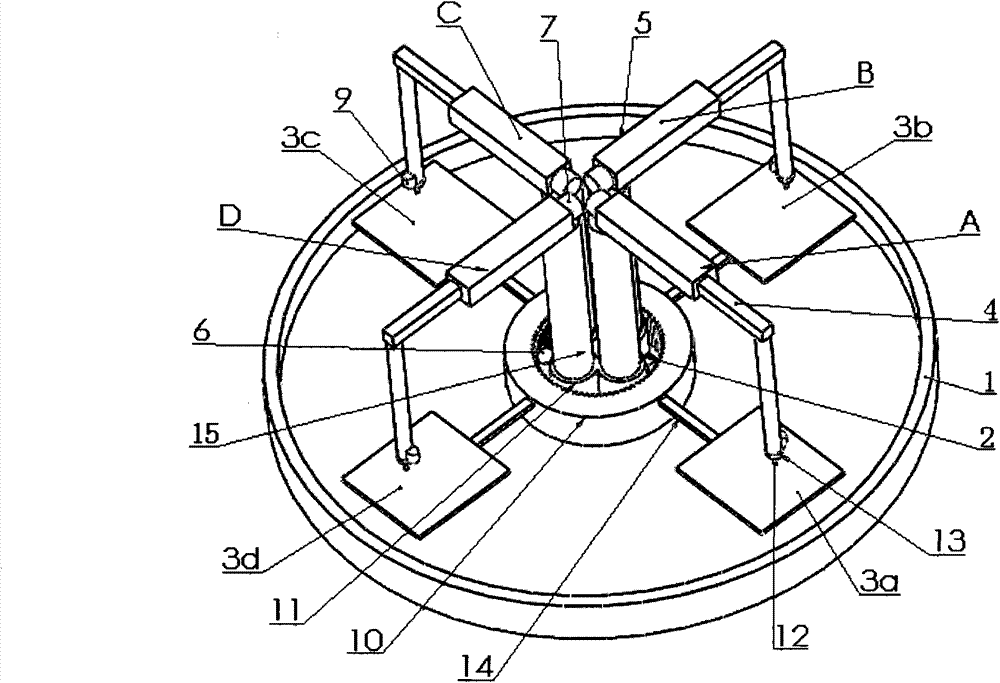

[0065] A multifunctional assembled 3D printing device provided by an embodiment of the present invention, such as Figure 5 As shown, the multifunctional assembled 3D printing device includes a circular chassis 1, a hydraulic pump station 2, multiple workbenches 3, a horizontal telescopic rod 4, a second hydraulic cylinder 5, a rotating motor 6, a circular rotating motor 7, and a raw material box 9. Gear ring 10, laser head or nozzle 12, working support 14, vertical lifting mechanism and horizontal telescopic mechanism, etc., which are also a deformation of a mechanical structure

[0066] Wherein, 4a, 4b, 4c are telescopic rods of hydraulic cylinders; 5a, 5b, 5c are hydraulic cylinders corresponding to the telescopic rods. 6a is that the workbench of the gear ring is driven by the external rotary motor to perform circular motion, and 6b is that the internal rotary motor drives 4 single machines to perform circular motion together. It not only satisfies the rotary motion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com