Hydrophobic surface dropwise condensation capillary force pickup and vibration control micro-object operation device and method

A technology of droplet condensation and hydrophobic surface, which is applied in the direction of manipulating single atoms, nanostructure manufacturing, nanotechnology, etc., can solve the problems of ineffective control of the operation droplet size, failure of operation tasks, etc., and achieve the effect of stable release and realization of release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

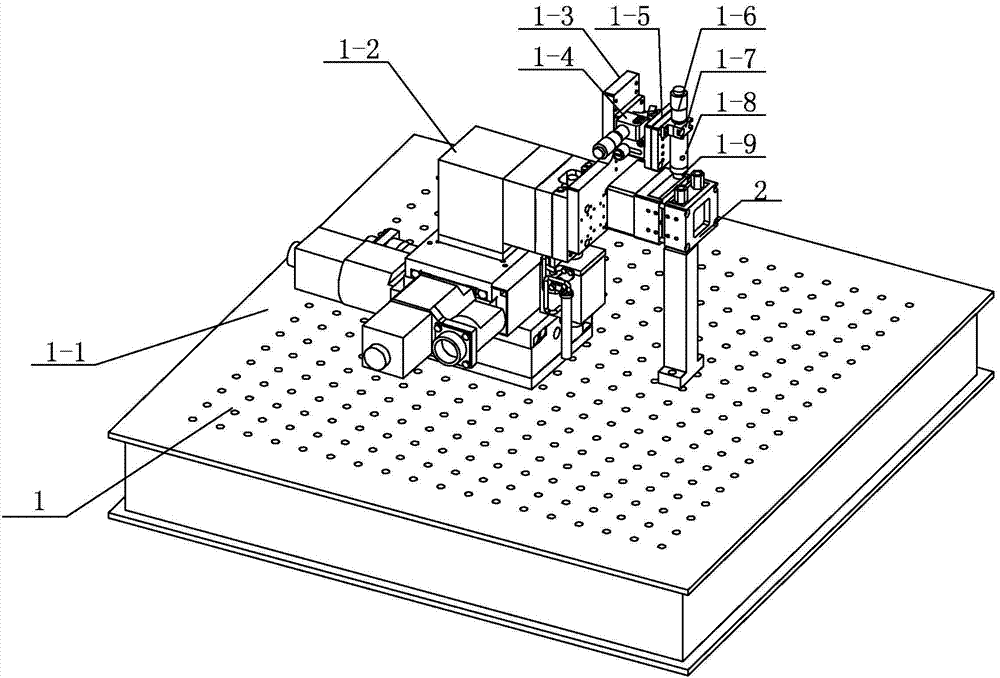

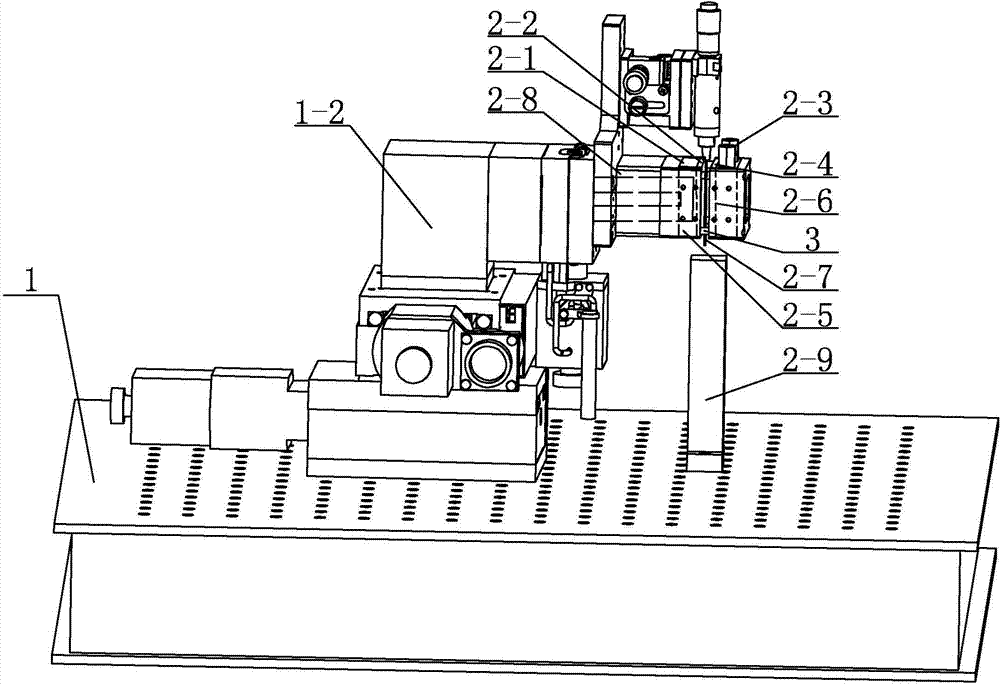

[0014] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, the micro-object operation device and method for capillary force pickup and vibration control of drop-like condensation on hydrophobic surfaces described in this embodiment, which includes a displacement control mechanism 1, a cooling operation mechanism 2 and four connecting studs 3, The displacement control mechanism 1 includes a vibration isolation table 1-1, a three-axis precision electric displacement platform 1-2, a connecting base plate 1-3, a manual displacement lifting table 1-4, a vibration module connection plate 1-5, and a micrometer head 1-6 , micrometer head fixture 1-7, piezoelectric ceramic vibration module 1-8 and probe fixture 1-9, refrigeration work operating mechanism 2 includes the first cooling head 2-1, the first cooling plate 2-2, the second Heat dissipation water block 2-3, second cooling plate 2-4, first cooling plate clamp 2-5, second cooling plate clamp 2-6...

specific Embodiment approach 2

[0017] Specific embodiment two: combine Figure 1-Figure 2 This embodiment will be described. The micro-object manipulation device and method for capillary force pick-up and vibration control of droplet condensation on a hydrophobic surface described in this embodiment, the vibration isolation table 1-1 is arranged horizontally.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination Figure 1-Figure 2 Describe this embodiment, the micro-object manipulation device and method for capillary force pick-up and vibration control of drop-like condensation on a hydrophobic surface described in this embodiment, the method is implemented according to the following steps:

[0019] Step 1: Configure dilute hydrochloric acid and FeCl with a mass fraction of 36% 3 ·6H 2 An etching solution composed of O and deionized water in a weight ratio of 2.4:12.5:30, and a hydrophobic solution composed of oxalic acid, heptadecafluorodecyltrimethoxysilane and absolute ethanol in a weight ratio of 3:4.62:240, The operating probes 2-7 are subjected to surface etching and fluorination treatment in sequence to make them hydrophobic;

[0020]Step 2: Pass the bottom end of the operation probe 2-7 under the first cooling plate 2-2 and the second cooling plate 2-4;

[0021] Step 3: Make the first refrigerating sheet 2-2 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com