Method for producing an environment-friendly enzyme organic fertilizer

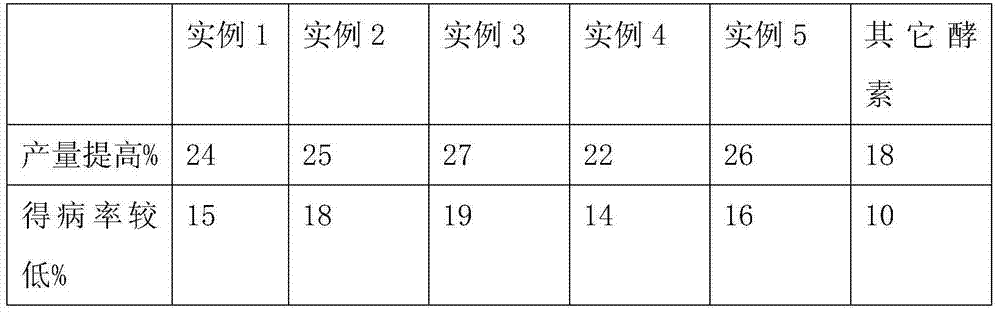

An environmentally friendly enzyme and production method technology, applied in organic fertilizer, biological organic part treatment, climate change adaptation and other directions, can solve the problems of reducing the quality and yield of organic fertilizer, long time, waste of nutrients, etc., to speed up the start of fermentation , The incidence of disease is reduced, and the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The production method of the environment-friendly ferment organic fertilizer is carried out according to the following steps:

[0029] (1) Put 1 kg of brown sugar and 9 kg of water in a closed container with a lid, leave 30% of the space in the container, and stir evenly;

[0030] (2) Put 4 kg of kitchen waste into the sugar water mixed in step (1), stir evenly, and fully mix with the sugar water;

[0031] (3) adjusting the pH value of the mixed solution to 4.0 with a concentration of 10mM / mL citric acid solution;

[0032] (4) add Saccharomyces cerevisiae by 400,000 Saccharomyces cerevisiae content in every liter of material liquid, stir;

[0033] (5) seal and carry out anaerobic fermentation, control the fermentation temperature to be 25°C, and the fermentation time is 6 months to obtain the fermentation feed liquid;

[0034] (6) Add sodium chloride according to the proportioning ratio of sodium chloride:fermentation feed liquid=1:80 parts by weight, and fully mix to...

Embodiment 3

[0046] The production method of the environment-friendly ferment organic fertilizer is carried out according to the following steps:

[0047] (1) Put 1 kg of brown sugar and 10 kg of water in a closed container with a lid, leave 20% of the space in the container, and stir evenly;

[0048](2) Put 3 kg of kitchen waste into the sugar water mixed in step (1), stir evenly, and fully mix with the sugar water;

[0049] (3) adjust the pH value of the mixed solution to 5.0 with a concentration of 10mM / mL citric acid solution;

[0050] (4) add Saccharomyces cerevisiae by 300,000 Saccharomyces cerevisiae content in every liter of material liquid, stir evenly;

[0051] (5) seal and carry out anaerobic fermentation, control the fermentation temperature to be 27°C, and the fermentation time is 4 months to obtain the fermentation feed liquid;

[0052] (6) Add sodium chloride according to the proportioning ratio of sodium chloride:fermentation feed liquid=1:90 parts by weight, and fully mi...

Embodiment 4

[0055] The difference is that 150,000 acetic acid bacteria are added in addition in step (4) according to the content of acetic acid bacteria in every liter of material liquid, and the others are respectively the same as in Examples 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com