Soft-taste style highland barley wine and preparation method thereof

The technology of highland barley wine and soft type is applied in the field of soft highland barley wine and its preparation, which can solve the problems of strong taste of highland barley wine, long production cycle, cumbersome production process, etc., and achieves improved aroma, low production cost and simplified process effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

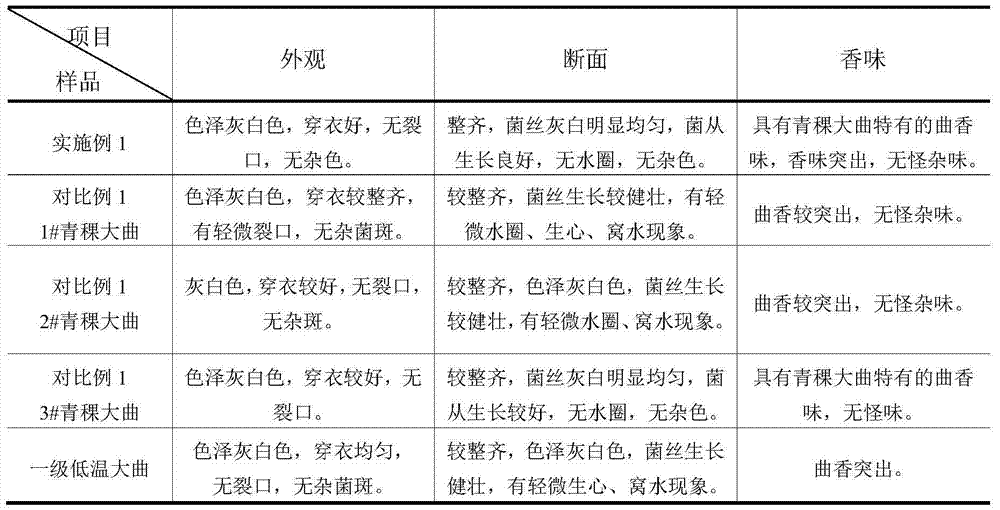

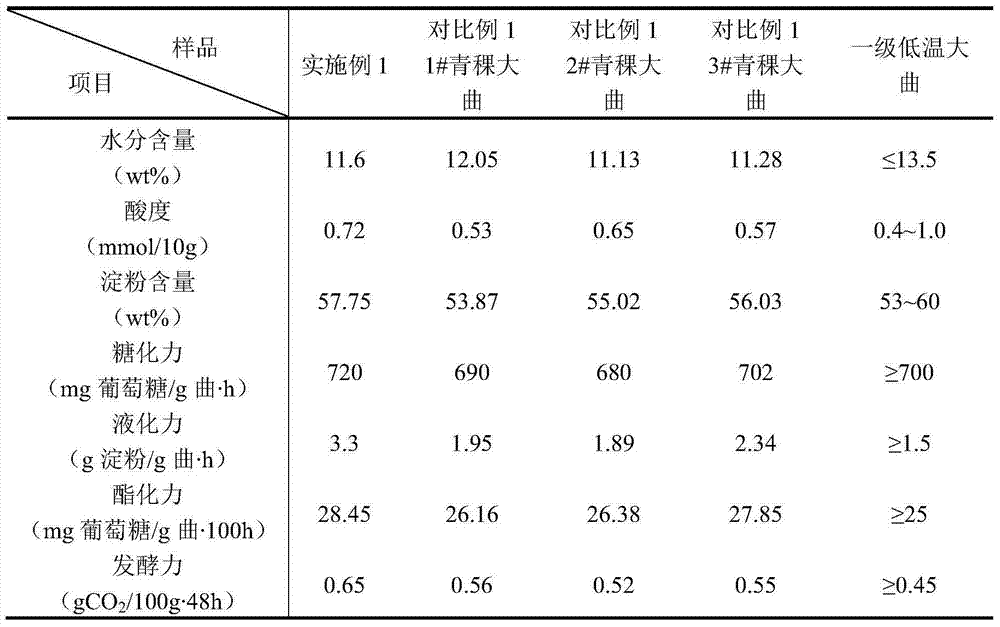

[0029] Example 1: Preparation of Highland Barley Daqu

[0030] In this embodiment, the preparation method of highland barley daqu is as follows:

[0031] ① The highland barley, peas and wheat are mixed according to the weight ratio of 6:2:2, and the total amount of the three is 100kg. The highland barley, peas and wheat are evenly mixed and crushed by a roller mill to obtain crushed materials. The fine powder that can pass through a 40-mesh sieve does not exceed 30% of the total weight of the powder; add 40kg of tap water to the crushed material and mix it evenly, then add the resulting mixture to a wooden curved box and manually press it to a size of 40cm× 30cm×10cm block curved blank;

[0032] ② Put the slab in the slab for 18 days to incubate the bacteria, and place the slab in the slab to turn it on the second, third, fourth, fifth, sixth, and eighth day. Turning refers to turning the slab inside out or Change the outside and inside, and then continue to incubate for 30 days. I...

Embodiment 2

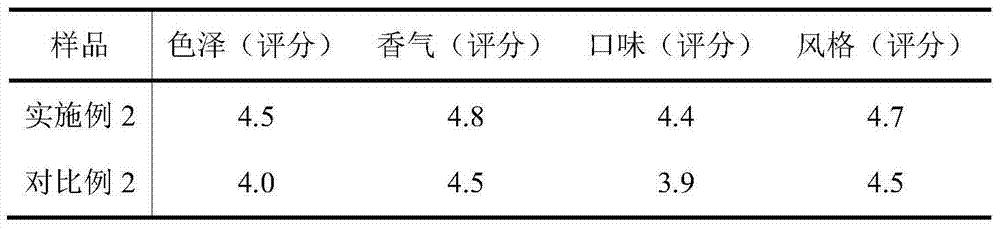

[0046] Example 2: Preparation of highland barley wine

[0047] In this embodiment, the preparation method of soft highland barley wine is as follows:

[0048] (1) Using highland barley and sorghum as raw materials, the weight ratio of highland barley to sorghum is 7:3, and the total weight of the two is 100kg. Mix the highland barley and sorghum evenly, and use a roller mill to crush. Among the raw materials, the fine powder that can pass through the 12-mesh sieve does not exceed 20% of the total weight of the raw materials, and the whole grain does not exceed 0.5% of the total weight of the raw materials.

[0049] The crushed raw materials are soaked in 60kg of tap water at a temperature of 50°C for 18 hours to facilitate cooking and gelatinization. After the soaking time expires, the soaking material is obtained by filtering and removing water.

[0050] (2) Take the highland barley daqu prepared in Example 1 and pulverize it with a roller mill. The fineness of the crushed daqu that ...

Embodiment 3

[0074] Example 3: Preparation of highland barley wine

[0075] In this embodiment, the preparation method of soft highland barley wine is as follows:

[0076] (1) Using highland barley and sorghum as raw materials, the weight ratio of highland barley to sorghum is 6:4, and the total weight of the two is 100kg. Mix the highland barley and sorghum evenly, and use a roller mill to crush. Among the raw materials, the fine powder that can pass through the 12-mesh sieve does not exceed 20% of the total weight of the raw materials, and the whole grain does not exceed 0.5% of the total weight of the raw materials.

[0077] The crushed raw materials are soaked in 50kg of tap water at a temperature of 60°C for 16h to facilitate cooking and gelatinization. After the soaking time expires, filter to remove water to obtain the soaking material.

[0078] (2) Take the highland barley daqu prepared in Example 1 and pulverize it with a roller mill. The fineness of the crushed daqu that can pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com