An ultrasonic spray pyrolytic coating device

A technology of ultrasonic spray pyrolysis and coating device, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., and can solve the problems of limiting the continuous operation of ultrasonic sprayers, large heat generation of ultrasonic sprayers, and long coating time, etc. Achieve the effects of product area and thickness control, ingenious structural design, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

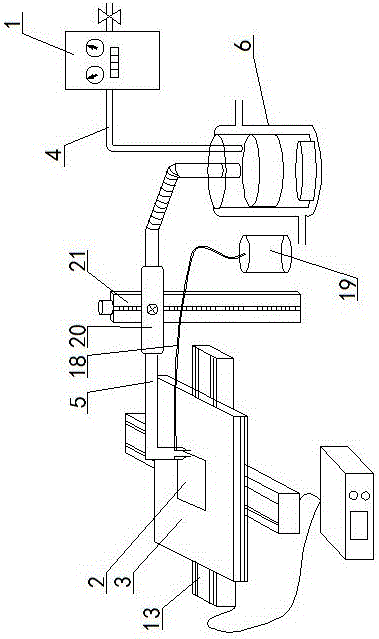

[0016] Embodiment 1: as figure 1 As shown, an ultrasonic spray pyrolysis coating device includes a gas cabinet 1, an ultrasonic atomization device, a spray head, and a heating table 3 with a substrate 2, and the gas cabinet 1 communicates with the ultrasonic atomization device through an air inlet pipe 4 , the ultrasonic atomization device communicates with the spray head through the pipeline 5, the spray head is located above the heating table 3 and corresponds to the heating table 3, an XY mobile platform 13 is arranged below the heating table 3, and the ultrasonic A cooling device is arranged outside the atomizing device.

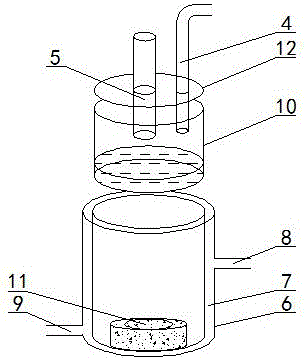

[0017] Such as figure 2 As shown, the cooling device of the present invention includes a double-layer cup body cooling barrel 6, a cooling chamber 7 is arranged between the double-layer cup bodies, and a cooling chamber communicated with the cooling chamber 7 is respectively provided at the upper and lower parts of the cooling barrel 6. Cooling water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com